PVC Waterproof Membrane in 1.5mm Thickness and Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Waterproof Membrane in 1.5mm Thickness

Product Description of PVC Waterproof Membrane in 1.5mm Thickness:

PVC Membrane Waterproof /Waterproofing membrane For Roof is a new polymer waterproof membrane. The PVC Membrane Waterproof /Waterproofing membrane For Roof raw material is polyvinyl chloride resin, mixed with plasticizer, filler, antioxygen, ultraviolet absorber and other auxiliaries.

Thickness: 1.2mm/1.5mm/1.8mm/2.0mm

Width:2050mm

Length:20m( Special specifications can be customized)

Size: 2.05mx20m

Color: white/grey, or any other colors.

Features of PVC Waterproof Membrane in 1.5mm Thickness:

1. Excellent aging resistance. Service life of roofing material is over 20 years; service life of underground material is over 50 years.

2. Root resistant penetration, specially used on planting roofings.

3. Welding installation. Joints are solid and environment friendly, no pollution.

4. High tensile strength, good elongation and dimensional stability.

5. Good plasticity, easy and suitable for details installation.

6. Fireproof. Fire extinguished out of the ignition resource.

7. Surface is smooth, no fading and dirty resistant.

8. Width is over 2m. Construction wastage is small, more economical.

Classification of PVC Waterproof Membrane in 1.5mm Thickness:

1. N: Homogeneous PVC membrane

2. L: PVC membrane with fabric backing

3. W: Reinforced PVC membrane

Advantage of PVC Waterproof Membrane in 1.5mm Thickness:

1.) Mixing automation. Apply automatic temperature control automatic time control and automatic feed control.

2.) Extrusion equipment uses twin screw coextrusion. Screw temperature uses computer automatic temperature control system.

3.) Handpiece uses large width didhead extrusion equipment.

4.) Sophisticated three-roller calender equipment. The space between equiment is controlled by automation system.

Technical Data of PVC Waterproof Membrane in 1.5mm Thickness:

No. | Item | Model Ⅱ | |

1 | Tensile Strength Mpa ≥ | 12.0 | |

2 | Elongation at break% ≥ | 250 | |

3 | Shrinkage rate % ≤ | 2.0 | |

4 | Flexibility at low temperature | No crackle at -25oC | |

5 | Water tightness | Watertight | |

6 | Puncture resistance | Watertight | |

7 | Heat aging treatment | Appearance | Free from bubble, crack, cohesion and void |

Change rate of tensile strength % | +20oC | ||

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

8 | Chemical corrosion resistance | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

9 | Artificial weathering | Change rate of tensile strength % | +20 |

Change rate of elongation at break | |||

Flexibility at low temperature | No crack at -20oC | ||

Application of PVC Waterproof Membrane in 1.5mm Thickness:

PVC waterproof membrane forms an effective barrier to liquid water or water vapor in the steel structure for industrial and civil engineering, underground engineering, such as subway, bridges , tunnel, water pools, shelter, grain depot, land filling and subwayProducts display.

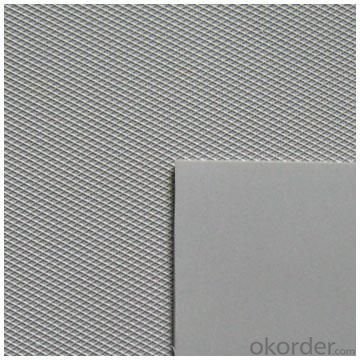

Images of PVC Waterproof Membrane in 1.5mm Thickness:

FAQ:

1. Can you produce 4m width?

Yes, no problem for us. We have four bases in China, largest one in this field.

2. How many quantity in one 20'' container for 1.2mm and 1.5mm?

480rolls, 11520m2 for 1.2mm and 400rolls, 9600m2 for 1.5mm

3. Can you provide free samples?

Yes, our samples are free, but express fees usually on buyer's account.

- Q:Can a waterproofing membrane be used on planter boxes?

- Planter boxes can indeed benefit from the use of a waterproofing membrane. Typically employed to prevent water from seeping through surfaces, a waterproofing membrane safeguards the wood or other materials of the planter box from moisture damage. When applied to the interior, this membrane acts as a barrier, stopping water from infiltrating the material and potentially causing decay or rot. Consequently, the planter box's lifespan is prolonged, ensuring it remains in excellent condition for an extended period. Moreover, the waterproofing membrane aids in retaining moisture within the planter box, which proves advantageous for the growth of plants or flowers. Overall, the application of a waterproofing membrane enhances protection and durability for planter boxes.

- Q:What is the best waterproofing membrane for my project?

- The best waterproofing membrane for your project depends on various factors such as the type of project, the specific requirements, and the budget. There are several options available in the market, each offering different features and benefits. One popular choice is a bituminous waterproofing membrane. It is a cost-effective option suitable for a wide range of projects, including roofs, basements, and foundations. Bituminous membranes are durable, flexible, and capable of withstanding extreme weather conditions. They can be applied using torch-on, self-adhesive, or hot-melt methods. Another option to consider is a polyurethane liquid membrane. This type of membrane provides excellent elasticity, making it ideal for areas that require flexibility, such as balconies, terraces, and swimming pools. Polyurethane membranes are resistant to UV rays and can be easily applied by brush or roller. For projects that require a high level of durability and resistance, a cementitious waterproofing membrane might be the best choice. It is a mixture of cement, sand, and special additives that create a thick, protective layer. Cementitious membranes are commonly used for underground structures, tunnels, and water tanks. If your project involves below-grade applications or areas with high water pressure, a bentonite waterproofing membrane could be the best option. Bentonite membranes are made of clay minerals that swell when exposed to water, forming a watertight barrier. They are commonly used in basements, foundations, and retaining walls. Ultimately, the best waterproofing membrane for your project will depend on the specific requirements, budget, and preferences. It is recommended to consult with a professional waterproofing contractor who can assess your project's needs and recommend the most suitable membrane system.

- Q:Can a waterproofing membrane be used in tunnels or underground structures?

- Yes, a waterproofing membrane can be used in tunnels or underground structures. Waterproofing membranes are designed to create a barrier against water penetration, making them effective in preventing water ingress in underground environments. These membranes are commonly used in tunnel construction to protect against moisture and water-related damages.

- Q:Can a waterproofing membrane be used on stone block surfaces?

- Stone block surfaces can indeed benefit from the use of a waterproofing membrane. This particular membrane is specifically designed to create a protective barrier against water and moisture, making it suitable for application on various surfaces, including stone blocks. By acting as a barrier, this membrane effectively prevents water from seeping into the stone and causing detrimental effects such as cracking, spalling, or efflorescence. It offers valuable protection against water-related issues such as freeze-thaw damage and the growth of mold and mildew. Moreover, the application of a waterproofing membrane can significantly enhance the durability and longevity of stone blocks by shielding them from water damage. Consequently, it is highly recommended to utilize a waterproofing membrane on stone block surfaces to ensure their long-term integrity and aesthetics.

- Q:Can a waterproofing membrane be used on parking garages?

- Indeed, utilizing a waterproofing membrane is highly recommended for parking garages to safeguard the structure against water damage. Parking garages are exposed to varying weather conditions, including rain, snow, and ice, which can lead to water infiltration through cracks, joints, or porous concrete. This infiltration can result in corrosion of reinforcing steel, degradation of concrete, and compromise the overall integrity of the structure. A waterproofing membrane serves as a specialized barrier system designed explicitly to impede water penetration and shield the underlying structure. Typically composed of materials like modified bitumen, PVC, or liquid applied coatings, the flexible membrane is applied to the surface of the parking garage, delivering a seamless and resilient waterproof barrier. Using a waterproofing membrane for parking garages offers numerous advantages. Firstly, it significantly prolongs the lifespan of the structure by shielding it from water-induced deterioration. Secondly, it upholds the structural integrity of the garage by preventing reinforcing steel corrosion, which can gradually weaken the structure. Furthermore, a waterproofing membrane maintains a dry and secure environment within the parking garage, thereby reducing the risk of slip and fall accidents. It is crucial to consider the specific requirements and conditions of the parking garage when selecting the appropriate waterproofing membrane. Factors such as the type of parking garage (underground, above ground, or rooftop), traffic volume, presence of vehicular fluids, and climate should all be taken into account when choosing the suitable waterproofing membrane system. In conclusion, to safeguard parking garages from water damage, extend their lifespan, and ensure a safe environment for users, the use of a waterproofing membrane is both viable and essential.

- Q:Can a waterproofing membrane be used for podium decks and plaza areas?

- Podium decks and plaza areas can benefit from the use of waterproofing membranes. These membranes are specifically designed to safeguard against water and moisture, and are widely utilized in different settings like roofs, basements, and decks. Considering that podium decks and plaza areas are also exposed to water and weather elements, they are ideal locations for installing waterproofing membranes. By acting as a waterproof layer, the membrane prevents water from infiltrating the underlying structure and causing any harm. It also plays a crucial role in preserving the durability and lifespan of the deck or plaza by shielding it from moisture-related problems such as leaks, mold, and deterioration. Moreover, there is a range of waterproofing membranes available in different types and materials, allowing for flexibility in selecting the most suitable option based on specific project requirements.

- Q:Can a waterproofing membrane be used in conjunction with a drainage system?

- Yes, a waterproofing membrane can be used in conjunction with a drainage system. In fact, it is often recommended to use both together for effective waterproofing and drainage in areas such as basements, roofs, and foundations. The waterproofing membrane acts as a barrier to prevent water from seeping through the surface, while the drainage system helps to remove any excess water that may accumulate. By combining these two systems, it ensures a comprehensive solution to protect the structure from potential water damage.

- Q:Can waterproofing membranes be used on rooftop terraces?

- Indeed, rooftop terraces can utilize waterproofing membranes. In fact, they are frequently employed to safeguard the terrace's structural integrity and prevent water damage to the underlying structure. Rooftop terraces are exposed to diverse weather conditions, encompassing rain, snow, and UV rays, which can result in leaks and deterioration. Waterproofing membranes function as a barrier, impeding water from permeating the surface and causing harm. These membranes are specifically engineered for outdoor usage and can endure the harsh conditions commonly encountered on rooftops. They are obtainable in various materials, such as modified bitumen, EPDM (ethylene propylene diene terpolymer), and PVC (polyvinyl chloride), allowing for flexibility in selecting the most suitable option for a specific terrace. Moreover, waterproofing membranes can be installed beneath a variety of terrace finishes, including pavers, tiles, and decking, offering a versatile solution for diverse design preferences. Overall, it is highly advisable to employ waterproofing membranes for rooftop terraces to ensure their longevity, durability, and resistance to water-related problems.

- Q:Can a waterproofing membrane be used for a roof?

- Yes, a waterproofing membrane can be used for a roof. Waterproofing membranes are specifically designed to provide a barrier against water penetration, making them an ideal choice for protecting roofs from leaks and water damage. They are durable, flexible, and can be applied to various types of roofs, including flat and sloped surfaces.

- Q:Can waterproofing membranes be used in swimming pools?

- Indeed, swimming pools can make use of waterproofing membranes. To prevent water leakage and safeguard the pool's structural integrity, it is common practice to employ waterproofing membranes in swimming pools. These membranes, often constructed from sturdy materials like PVC or EPDM, are specifically engineered to endure continuous exposure to water and pool chemicals. They are applied to the concrete or other pool structures, forming a watertight barrier that thwarts any seepage of water. Furthermore, waterproofing membranes offer an added layer of defense against cracks, corrosion, and other types of harm, thus guaranteeing the long-lastingness and resilience of the pool.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Waterproof Membrane in 1.5mm Thickness and Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords