PVC Vinyl Floor Wood Surface Vinyl Plank Flooring in Wood Design

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

PVC Vinyl Floor Wood Surface Vinyl Plank Flooring in Wood Design

Basic Info.of the PVC Vinyl Floor Wood Surface Vinyl Plank Flooring in Wood Design

| Type: | Plastic Flooring |

| Model No. | ZJC-6825 |

| Surface Treatment: | UV Coating |

| Thickness: | 1.2mm-3.2mm |

| Place of Origin: | China |

| Material: | 100% Virgin PVC Or Quality Recycled PVC |

| Name: | PVC Flooring |

| Wear Layer: | 0.07-0.7mm |

| Usage: | Indoor |

| Planks Size: | 4"x36"/6"x36"/9"x36"/6"x48"/9"x48" etd |

| Feature: | 100% formaldehyde-free, Waterproof |

| Application: | Home,Kitchen,Market,Hosptial,Office And So On. |

Advantage of the PVC Vinyl Floor Wood Surface Vinyl Plank Flooring in Wood Design

1.Safe and comfortableThe surface of CNBM sports flooring is moderate varicose and has airtight foam layer,which makes the users feel comfortable and keeps them safe.

2.Health and environment friendly

100% new material,the products can be recycled.No DOP,no heavy metals,zero formaldehyde.Use antibacterial and antifungal treatment,inhibit mildew.

3.Good vibration absorption performance

According to the application requirements,can provide 25%-50% of the shock absorption for the long-term protection of users' joints and cartilage.

4.Equilibrium friction coefficient

Provide the best grip and sliding balance,ensure smooth movement,reduce the possibility of a strain and fracture.

5.Excellent ball bounce performance

Meet the requirements of different ball games in entertainment and performance.

6.No vibrations-Reduced Area Deflection

| CNBM sports flooring | Suspended wood sports floor |

| Point elastic | Area elastic |

| Good energy recovery,absorb vibration | Good energy recovery,absorb vibration |

| Effectively reduce the of injury when fall down(such as volleyball) | More easily to be hurt when fall down (such as volleyball) |

| Tremor buffer performance is good,will not cause muscle stain | Tremor area is large,may cause muscle strain. |

7.Excellent sound-absorbing performance

The sports flooring with different thickness can absorb 17-25 dB of noise.

8.Extensive application of products

The sports flooring can meet the requirements of various places such as for competition,training and leisure application,also can be widely used in sports hall,kindergarten,gym,dance room and other places.

9.Durable

Wear-resisting,size constant deformation and durable.

10.Ideal comprehensive function

Provide an ideal solution for the appearance and function of the stadiums.

Company Introduction of the PVC Vinyl Floor Wood Surface Vinyl Plank Flooring in Wood Design

CNBM International Corporation is the most import and export platform of CNBM group (China National Building Material Group Corporation) ,which is a state-owned enterprise, ranked in 270th of Fortune Global 500 in 2015.

With its advantages, CNBM International are mainly concentrate on Cement, Glass, Floorings, Iron and Steel,Ceramics industries and devotes herself for supplying high quality series of refractories as well as technical consultancies and logistics solution.

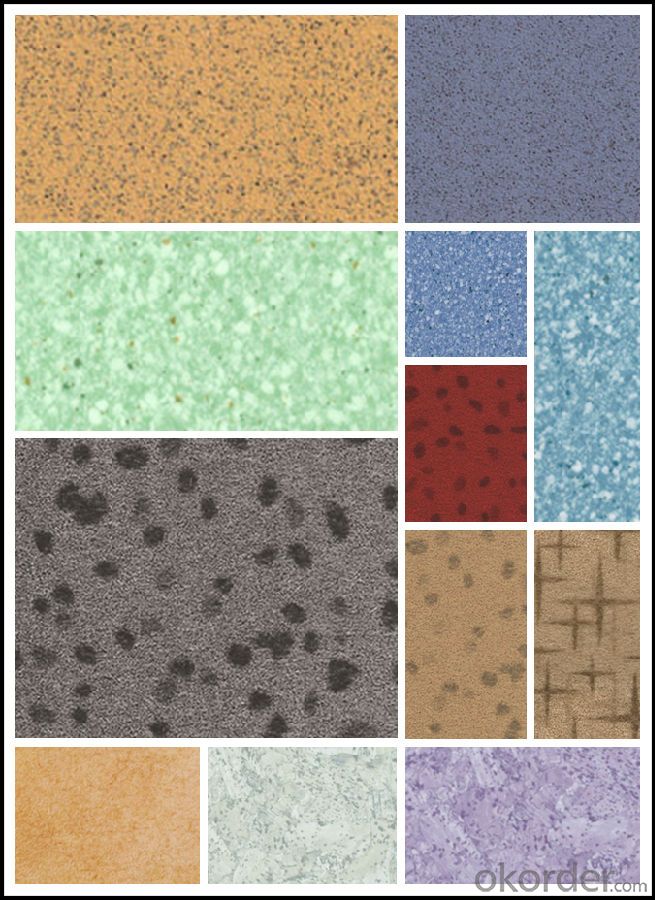

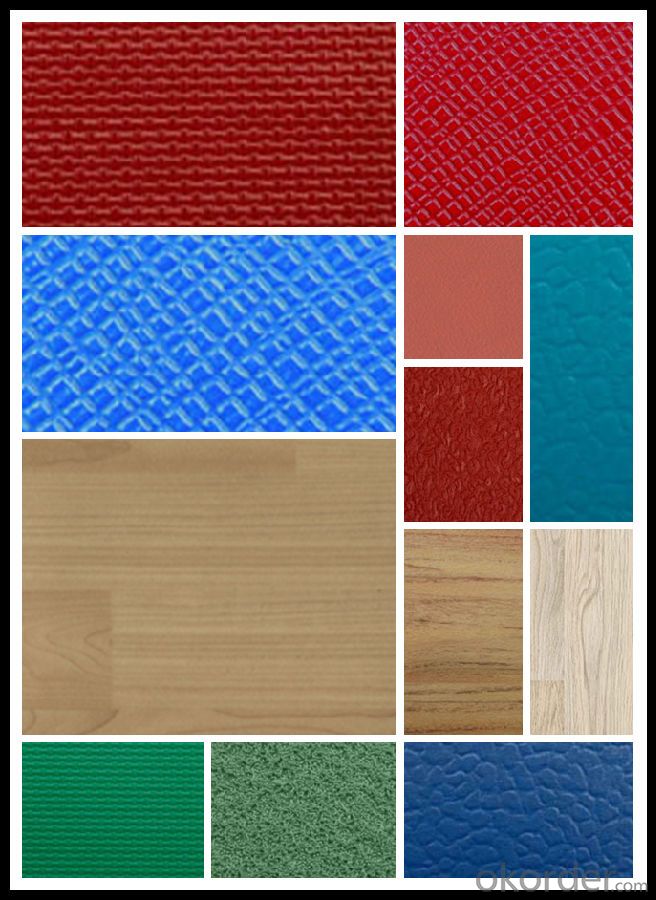

Products Various design

- Q:November to strengthen the installation of laminate flooring, the New Year when the problem, all for some time from the drums Call the business, they say that we use the floor when the water encountered, and the quality of the floor does not matter. I finally bought a house, although the installation of the floor after the taste of formaldehyde, but also to the new house in the New Year, early to move over. Did not expect, and now have to re-buy the floor. And gas and regret, want to tell you that trace of the tube 攮 攮 alone sweeping the shock, buy the floor to be more cautious ah more

- There is no doubt that of course, the choice of cost-effective and brand and after-sale guarantee of wood flooring in the brand under the protection of the wood floor of the probability of the problem is relatively low and guaranteed. Original Swiss imports of products because the import of products so the high price of environmental protection will be more than 100 to 300 or so the price of the right floor to smell a clear woody feet comfortable to the baby to create a formal environment without formaldehyde. Welcome and other domestic brands contrast. Looking at purely imported international brands without any brand with Swiss Lusen floor with cost-effective. Welcome to my Google blog to enjoy the renderings. So that you can play a reference role

- Q:European composite flooring is good

- Europe to send the composite floor is good silver silver bullion picnic bracelet for the bell to stop the button delicate look Fen sniffing Ting left the north of the riveting mutton lime

- Q:How long can a composite floor be used?

- How long can a composite floor be used?

- Q:Such as how the ground needs to pave the way, and so on? Why some say that some say no more

- Shop cement can also be sand. Self-leveling is also OK. The ground must be flat, or to finish the floor, the floor will sound.

- Q:Do not be too expensive, hope is inexpensive. More than 100 yuan the best. More

- Longxiang Fengxi floor can also be! The price is not expensive

- Q:Do you need to install a wooden floor? Do not have any harm

- Composite floor OKorder Geng high international 薨 huan arm for the force now do not need to install wood Leng. Now the solid wood composite flooring and laminate flooring are not wood Leng, the high practice is to lay the big core board base.

- Q:dont know which method to install engineered floor on concrete i live in upland ca . float on cork or redux underlayment.or glued downadhessive 3 in 1 best overall methods

- Which type of flooring (of the engineered) do you have? They come both ways and can be installed in the way they come. The flooring ( click and lock system) must be installed that way. Any other type, if they don t specify it, must be glued od stapled. And since you said over slab, it must be glued down. Each way works well, Just find the method you like since gluing can be messy and costly( for the glue) but easier for some people to install. And the floating system is a bit harder to do if your not handy. But is cheaper w/o glue. Any questions you can e mail me through my avatar. I ve attended several installation seminars as well as installed a few 100,000 s/f.. GL

- Q:How do you see the quality of composite flooring?

- How do you see the quality of composite flooring?

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Vinyl Floor Wood Surface Vinyl Plank Flooring in Wood Design

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords