PVC Transparent Sheet Used for Desk Top

- Loading Port:

- TianJin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

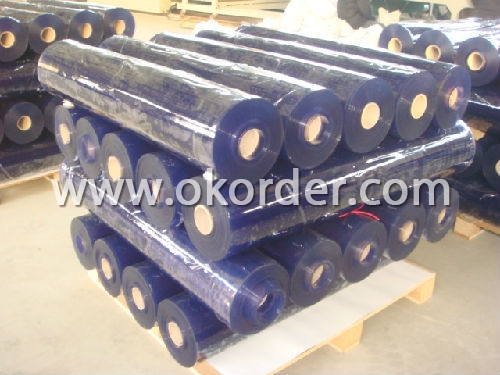

Specifications of Factory-sale PVC Transparent Sheet Use For Desk Top

Flexible PVC sheet is widely applied for purpose of building and industrial partition ,swing doors,furniture protection,we can provide different dimensions and color solutions for customer's requirement of pvc sheet,which application temperature range from -15 ℃ to +50 ℃,different match of width,thickness and color bring out difference pvc sheet solutions and applications.

* width solution:

600mm/800mm/900mm/1000mm/1200mm/1300mm/1400mm/1500mm/1600mm/1800mm

* thickness solution:

1mm/1.5mm/2mm/3mm/4mm/5mm/6mm/7mm/10mm

Applications of Factory-sale PVC Transparent Sheet Use For Desk Top

I) these 1mm/1.5mm/2mm pvc sheet is ideal for application such as the partition of workshops and warehouses,printing,furniture protection,building insulation.

II) these 2mm/3mm pvc sheet is ideal to manufacture automatic roll-up doors,or if compatible,fully transparent light duty swing door panels for pedestrians.

III) these 4mm/5mm/6mm/7mm/10mm thickness sheet is best suitable for manufacturing of fully transparent light weight flexible doors,or the upper part of two color doors.

Package& Delivery of Factory-sale PVC Transparent Sheet Use For Desk Top

Wooden pallet,shirnk film according to custom requires.

Colors of Factory-sale PVC Transparent Sheet Use For Desk Top

clear: blue/yellow/nature

opaque: black/silver grey/milk white

- Q:How does the choice of plastic in electric canister vacuum bodies affect durability?

- The choice of plastic in electric canister vacuum bodies can significantly affect durability. High-quality, durable plastics, such as ABS or polycarbonate, offer excellent impact resistance, heat resistance, and overall strength. These plastics are less likely to crack, break, or deform under normal usage conditions, making the vacuum body more resistant to damage. On the other hand, using low-quality or brittle plastics may result in a vacuum body that is more prone to cracking, breaking, or wearing down over time, reducing its overall durability and lifespan. Therefore, selecting the right plastic for the vacuum body is crucial in ensuring its long-term durability.

- Q:How do plastic home appliances compare in terms of fire resistance?

- Plastic home appliances vary in terms of fire resistance, as it depends on the specific type and quality of plastic used. Some plastic materials can be inherently fire-resistant or have additives to enhance their fire resistance. However, not all plastics offer the same level of protection, and some may be more susceptible to fire hazards. It is crucial to check the fire resistance ratings and safety features of plastic home appliances before purchasing and using them to ensure proper fire safety precautions.

- Q:Are there any specific cleaning methods or products recommended for plastic parts in home appliances?

- Yes, there are specific cleaning methods and products recommended for plastic parts in home appliances. It is generally recommended to use mild soap or a non-abrasive cleaner along with a soft cloth or sponge to clean plastic parts. Harsh chemicals and abrasive cleaners should be avoided as they can damage the plastic. Additionally, it is important to follow the manufacturer's instructions and guidelines for cleaning and maintenance to ensure the longevity of the plastic parts in home appliances.

- Q:Are there any specific guidelines for using home appliances with plastic parts in high-humidity environments?

- Yes, there are specific guidelines for using home appliances with plastic parts in high-humidity environments. It is recommended to choose appliances with plastic parts that are specifically designed for high-humidity conditions. Additionally, it is important to ensure proper ventilation and air circulation to minimize moisture buildup. Regular cleaning and maintenance of these appliances is also crucial to prevent mold or mildew growth.

- Q:How does the texture or finish of plastic parts in home appliances affect user experience?

- The texture or finish of plastic parts in home appliances can significantly impact the user experience. A smooth and sleek finish enhances the overall aesthetic appeal, making the appliance look more modern and sophisticated. It also makes the appliance easier to clean and maintain. On the other hand, a textured or matte finish can provide a better grip and prevent slipping, ensuring safer handling of the appliance. Additionally, the texture or finish can also affect the perceived quality and durability of the product, influencing the user's confidence and satisfaction with their purchase.

- Q:Are there any health concerns with plastic parts in air conditioners?

- Yes, there can be health concerns associated with plastic parts in air conditioners. Some plastics used in air conditioners may release harmful chemicals such as phthalates, bisphenol A (BPA), or volatile organic compounds (VOCs) when exposed to heat or sunlight. These chemicals can potentially cause respiratory issues, allergies, hormone disruption, or contribute to indoor air pollution. It is important to ensure that air conditioners meet safety standards and regulations to minimize any potential health risks.

- Q:Can plastic home appliances be easily operated and controlled?

- Yes, plastic home appliances can be easily operated and controlled. The use of plastic in the manufacturing of appliances allows for lightweight and user-friendly designs. Additionally, the incorporation of modern technologies and intuitive control interfaces further enhances the ease of operation for users.

- Q:Can home appliance plastics be customized or personalized?

- Yes, home appliance plastics can be customized or personalized. Manufacturers often offer options for customers to select different colors, finishes, or even add custom designs to their appliances. This allows consumers to match their personal style or the aesthetic of their home. Additionally, some companies may offer personalized engravings or labels on the appliance, further enhancing the customization options.

- Q:How do plastic parts in fans and heaters handle constant temperature changes?

- Plastic parts in fans and heaters are designed to handle constant temperature changes by using materials that have good thermal stability and resistance to heat. These materials are carefully selected to ensure that the plastic parts do not deform or degrade when exposed to fluctuating temperatures. Additionally, the design and manufacturing process of these parts take into consideration the expansion and contraction that can occur due to temperature changes, allowing them to maintain their structural integrity over time.

- Q:Can plastic parts in air conditioners handle the constant exposure to outdoor elements like rain and sunlight?

- Plastic parts in air conditioners are typically designed to withstand outdoor elements like rain and sunlight. They are made from durable materials such as high-quality plastics or polymers that are UV-resistant and water-resistant. However, it is essential to consider the specific brand and model of the air conditioner, as the quality and durability of plastic parts can vary. Additionally, regular maintenance and proper care can significantly prolong the lifespan of these plastic components.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

PVC Transparent Sheet Used for Desk Top

- Loading Port:

- TianJin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords