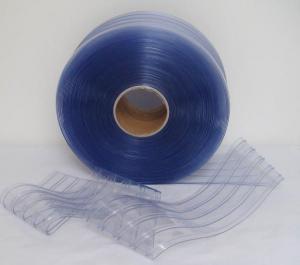

PVC Transparent Sheet in Soft Type

- Loading Port:

- TianJin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Soft PVC Transparent Sheet

Flexible PVC sheet is widely applied for purpose of building and industrial partition ,swing doors,furniture protection,we can provide different dimensions and color solutions for customer's requirement of pvc sheet,which application temperature range from -15 ℃ to +50 ℃,different match of width,thickness and color bring out difference pvc sheet solutions and applications.

* width solution:

600mm/800mm/900mm/1000mm/1200mm/1300mm/1400mm/1500mm/1600mm/1800mm

* thickness solution:

1mm/1.5mm/2mm/3mm/4mm/5mm/6mm/7mm/10mm

Applications of Soft PVC Transparent Sheet

I) these 1mm/1.5mm/2mm pvc sheet is ideal for application such as the partition of workshops and warehouses,printing,furniture protection,building insulation.

II) these 2mm/3mm pvc sheet is ideal to manufacture automatic roll-up doors,or if compatible,fully transparent light duty swing door panels for pedestrians.

III) these 4mm/5mm/6mm/7mm/10mm thickness sheet is best suitable for manufacturing of fully transparent light weight flexible doors,or the upper part of two color doors.

Package& Delivery of Soft PVC Transparent Sheet

Wooden pallet,shirnk film according to custom requires.

Colors of Soft PVC Transparent Sheet

clear: blue/yellow/nature

opaque: black/silver grey/milk white

- Q:How does plastic affect the overall reliability of home appliances?

- Plastic can both positively and negatively impact the overall reliability of home appliances. On one hand, plastic components in appliances can contribute to their durability by being lightweight, corrosion-resistant, and less prone to breakage. Additionally, plastic parts often help reduce costs, making appliances more affordable for consumers. However, excessive use of low-quality or cheap plastic materials can compromise the reliability of appliances, resulting in shorter lifespan, frequent repairs, and reduced performance. Therefore, the choice of plastic materials and their quality play a significant role in determining the overall reliability of home appliances.

- Q:What are the most common types of plastic used in refrigerator components?

- The most common types of plastic used in refrigerator components are polypropylene (PP), polystyrene (PS), and acrylonitrile butadiene styrene (ABS).

- Q:Can plastic parts in home appliances be affected by exposure to magnetic fields?

- Yes, plastic parts in home appliances can be affected by exposure to magnetic fields. Magnetic fields can induce electric currents in the plastic, leading to heating or distortion of the material. However, the extent of the impact depends on factors such as the strength and duration of the magnetic field, as well as the specific properties of the plastic used.

- Q:How does the flame resistance of plastic affect the safety of home appliances?

- The flame resistance of plastic significantly enhances the safety of home appliances. By using flame-resistant plastic materials in the construction of appliances, the risk of fire accidents is greatly reduced. This is especially crucial for devices that generate heat or have electrical components, as the flame-resistant properties of the plastic help prevent the spread of fire and limit potential damage. The ability of plastic to withstand high temperatures without igniting or releasing toxic fumes ensures that home appliances can operate safely and reliably, providing peace of mind to users.

- Q:Can home appliance plastics be easily customized for different appliance brands?

- Yes, home appliance plastics can be easily customized for different appliance brands. Manufacturers can modify the color, texture, shape, and branding elements of the plastic components to match the specific requirements and aesthetics of each appliance brand.

- Q:What types of plastic are commonly used in electric grater and slicer bodies?

- The types of plastic commonly used in electric grater and slicer bodies are typically food-grade and durable plastics such as ABS (Acrylonitrile Butadiene Styrene) or polycarbonate. These plastics offer good strength, impact resistance, and are safe for contact with food.

- Q:Can plastic parts in washing machines be affected by water and detergent?

- Yes, plastic parts in washing machines can be affected by water and detergent. The constant exposure to water and detergent can cause certain types of plastic to degrade over time, leading to cracking, warping, or even complete failure of the plastic components. It is important to choose washing machines with high-quality and durable plastic parts to minimize the risk of damage.

- Q:How do home appliance plastics compare to metal appliances in terms of durability?

- Home appliance plastics generally have a lower durability compared to metal appliances. While plastics are lightweight and cost-effective, they can be prone to cracking, warping or breaking over time. Metal appliances, on the other hand, are known for their sturdiness and resilience, making them more durable in the long run.

- Q:Can plastic parts in home appliances be affected by physical impact or dropping?

- Yes, plastic parts in home appliances can be affected by physical impact or dropping. Plastic is a relatively brittle material compared to other metals, and it can crack, break, or deform under the force of a physical impact. Dropping an appliance can cause damage to its plastic parts, leading to functionality issues or even rendering the appliance unusable. It is important to handle home appliances with care to avoid such damages.

- Q:What are the aesthetic considerations when using plastic in home appliances?

- When using plastic in home appliances, aesthetic considerations involve the overall appearance, texture, color, and finish of the plastic materials. Designers and manufacturers take into account factors such as the desired style, visual appeal, and harmony with the surrounding environment. Additionally, considerations like durability, ease of cleaning, and resistance to wear and tear are also important to ensure that the plastic components maintain their aesthetic appeal over time.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei, China |

| Year Established | 1991 |

| Annual Output Value | US$ 1 Million - US$ 2.5 Million |

| Main Markets | 40.00% Southeast Asia 15.00% Mid East 10.00% South America 5.00% Southern Europe 5.00% Northern Europe 5.00% Western Europe 5.00% Oceania 5.00% Africa 5.00% Eastern Europe 5.00% North America |

| Company Certifications | ISO 9001:2000; |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 81% - 90% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 40,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

PVC Transparent Sheet in Soft Type

- Loading Port:

- TianJin Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 20 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords