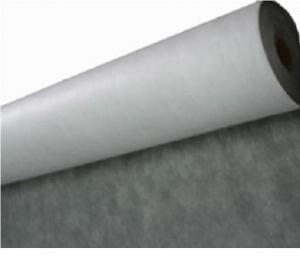

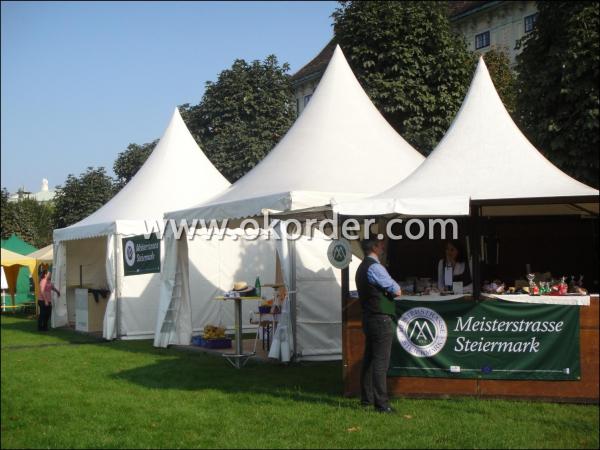

PVC Tarpaulin for Covers and Tents

- Loading Port:

- Wuhan

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Meter m²

- Supply Capability:

- 20 Containers Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC tarpaulin, is vinyl coated fabtic with characteristics of light-weight, fire-retardant,good tensile strength, easy to print,waterproof, UV protection,long-lifetime etc. is an idea covering material in different fields.

Specification of PVC tarpaulin

Product :PVC Tapaulin for Covers and Tents

Weight : 240gsm-1000gsm

Width :1.0-3.2m

Yarn(Denier) :200D,300D,500D,840D,1000D,1200D etc.

Yarn count : 9*9,18*12,17*30,20*20,30*30

Color :customized

Special treatment :UV proteciton, flame resistance(B1,M2 level etc),acrylic coating, anti-static, customized

Application of PVC tarpaulin:

Tarpaulin has multiple use in agricultural, industrial and transportation field etc,such as

Tarpaulin for train cover and construction site cover;

Tarpaulin for shelter from the elements, such as rain, wind,sunlight or relief tent, party tent, pavilion,canopy

Tarpaulin for ventilation duct,,

Tarpaulin for inflatable toys, inflatable boat

Tarpaulin for advertisement digital printing

- Q:Why do the basics of the cushion waterproofing

- The general basis of the foundation, the bar base is not necessary to do, like a raft in the basement, it is necessary to prevent the water from dipping into the basement (so the basement design may have to do anti-floating calculations). Assuming (just suppose) the raft can easily turn over, then we do waterproof (like roof) directly on it, not waterproof on the cushion.

- Q:Is foam concrete suitable for use as a cushion?

- The foamed concrete is a foaming system through a foaming machine that allows the foaming agent to be fully mechanically foamed and the foam is mixed evenly with the slurry.

- Q:Basement floor mattress dry to what degree can do coil waterproof?

- Third, the membrane waterproof in the construction should first do the basement floor of the waterproof, and then the membrane along the basement floor continuous paste to the outer surface of the wall. Basement floor waterproofing first in the foundation pouring C10 concrete cushion, the thickness of about 100mm. And then paste the membrane, and then in the coil to wear 20 thick 1: 3 cement mortar, and finally pouring reinforced concrete floor. The outer surface of the wall first wip 20mm thick 1: 3 cement mortar, cold base oil, and then paste the membrane, the membrane should be stitched paste, adjacent coil lap width of not less than 100mm. The top of the coil should be higher than the maximum water level of about 500mm, the outer side of the brick wall.

- Q:What is the relationship between the cushion and the ring beam?

- Ring beam is reinforced concrete. Is to increase the overall wall and overall stiffness, improve the side resistance performance, according to the earthquake or masonry specifications set. There may be in the ground wall, there may be in the underground wall.

- Q:Do you need a cushion on the ground floor?

- First to ask the use of your huts, there is the strength of the huts. If you just get a little, then a few years into a dangerous floor, then calculate the ground, walls, roof (slope roof) area, doors and windows can be used as a wood plate loss.

- Q:Roof waterproof mattress should play the number of centimeters appropriate

- Roof leaking of the construction program: ? 1. Need to remove the previous waterproof, such as paint, coil, etc., if it is to do the mortar waterproof can not be eradicated.

- Q:How to build a fine stone concrete cushion?

- Reduce ground cracking, plus steel mesh. Reinforced mesh, should be placed in the middle of the concrete, because the protective layer of concrete thick Fang generally only 5CM thickness, so the middle is the best.

- Q:When the cushion is used, the thickness of the protective layer is not less than ()

- Basement roof: non-load protection layer generally use C20 fine stone concrete or reinforced concrete, the thickness of 50 ~ 80mm. The road, driving the protective layer is determined by design.

- Q:Basement cushion waterproof

- Second, when the design of the highest groundwater level above the bottom of the basement floor, you must do waterproofing. As the waterproof waterproof effect is good, so the application of more. Internal waterproofing is generally used for repair works.

- Q:Can the floor tiles be removed from the cement mats on the prefabricated board floor?

- Cement cushion as a leveling layer on the floor, not designed to the structure of the load-bearing, the general can be dug, the cushion is generally 3 to 5 cm, chisel in addition to unloading the floor of the heavy objects, chisel in addition to the use of strong vibration Machine or penetrating machine is too large, with a small hammer small chisel, along the horizontal plane horizontal chisel, stripping cement cushion.

1. Manufacturer Overview |

|

|---|---|

| Location | Hubei,China |

| Year Established | 1990 |

| Annual Output Value | Above US$100 Million |

| Main Markets | |

| Company Certifications | ISO9001 Certificate |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Wuhan |

| Export Percentage | 31% - 40% |

| No.of Employees in Trade Department | 15 People |

| Language Spoken: | English;Chinese |

| b)Factory Information | |

| Factory Size: | 10,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | High;Average |

Send your message to us

PVC Tarpaulin for Covers and Tents

- Loading Port:

- Wuhan

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 Meter m²

- Supply Capability:

- 20 Containers Per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products