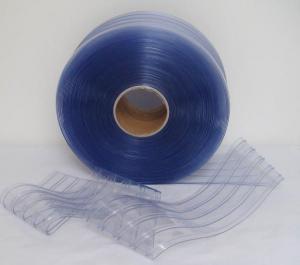

PVC Strip Door Curtain Used for Food Factory

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Best Selling PVC Strip Door Curtain

1. the CHEAPEST and the FASTEST solution to divide small or large rooms.

2.Strips: made of transparent or coloured plastic in full or partial overlap and are supported by fixed or sliding metal junctions.

3.can create real partion walls suitable to divide rooms and sheds.

4.a barrier against bugs and birds. they can be installed either in food or in pharmaceutical areas.

5.Suitable for LOW TEMPERATURES: -50 °C to -50 °C is also available.

6.Easy and quick to install and do not require any particular maintenance.

7.Solid or sliding track manufactured in either stainless or galvanized finishes.

8.This product is manufactured to suit the clear open specified by the client.

Applications of Best Selling PVC Strip Door Curtain

PVC flexible strip doors are widely used in the following area:

Door construction, lamellar doors

Trade and industry

Seperation of production and storage sites

Cold stores,cold store depots

Door area screening for cold stire vehicle

Coloured warning strips for industrial doors

As a view protection, also with frosted surfaces

Package& Delivery of Best Selling PVC Strip Door Curtain

Wooden pallet,shirnk film according to custom requires.

Colors of Best Selling PVC Strip Door Curtain

Blue, Green, Orange, White and Yellow.

Other colours are available on request.

- Q:What are the common plastic components found in microwaves?

- Some common plastic components found in microwaves include the control panel, door handle, buttons, and the interior cavity.

- Q:How does plastic contribute to the ease of installation for home appliances?

- Plastic contributes to the ease of installation for home appliances by being lightweight, durable, and flexible. These characteristics make it easier to handle and transport appliances, reducing the physical effort required during installation. Additionally, plastic components can be molded into various shapes and sizes, allowing for precise fitting and easy assembly.

- Q:Can home appliance plastics be made from biodegradable materials?

- Yes, home appliance plastics can be made from biodegradable materials. Biodegradable plastics are designed to break down naturally through the action of microorganisms, reducing their impact on the environment. These materials can be used to manufacture various components of home appliances, offering a more eco-friendly alternative to traditional plastics.

- Q:How does plastic contribute to the noise level of home appliances?

- Plastic components in home appliances can contribute to the noise level by transmitting and amplifying vibrations and mechanical sounds.

- Q:How does plastic impact the overall ease of use of home appliances?

- Plastic greatly enhances the overall ease of use of home appliances due to its lightweight nature, durability, and versatility. It allows for the creation of ergonomic designs, making appliances easier to handle and maneuver. Moreover, plastic parts often contribute to smoother operation, as they reduce friction and noise. Additionally, plastic's resistance to corrosion and heat ensures the longevity of appliances, while its ability to be molded into various shapes enables the inclusion of intricate features that enhance functionality. Overall, plastic positively impacts the ease of use, performance, and lifespan of home appliances.

- Q:Are there any innovations or advancements in plastic technology for home appliances?

- Yes, there have been several innovations and advancements in plastic technology for home appliances. Manufacturers are now using more durable and heat-resistant plastics in the production of appliances, making them more reliable and long-lasting. Additionally, there have been advancements in plastic coatings and finishes that enhance the aesthetics of appliances, giving them a sleek and modern look. Furthermore, there are ongoing efforts to develop eco-friendly and recyclable plastics for home appliances, reducing their environmental impact. Overall, these advancements in plastic technology are improving the performance, durability, and sustainability of home appliances.

- Q:Can plastic parts in home appliances be affected by exposure to ultraviolet (UV) radiation?

- Yes, plastic parts in home appliances can be affected by exposure to ultraviolet (UV) radiation. UV radiation can cause plastic to degrade, become brittle, fade in color, and potentially crack over time. Therefore, it is important to protect plastic parts from prolonged exposure to UV radiation to ensure their longevity and functionality.

- Q:Can home appliance plastics be easily repaired if they develop stress marks?

- No, home appliance plastics cannot be easily repaired if they develop stress marks.

- Q:Can plastic parts in home appliances be affected by exposure to harsh weather conditions?

- Yes, plastic parts in home appliances can be affected by exposure to harsh weather conditions. Extreme temperatures, such as excessive heat or cold, can cause the plastic to warp, crack, or become brittle. Additionally, prolonged exposure to sunlight can lead to discoloration and degradation of the plastic material. It is important to protect home appliances from harsh weather conditions to maintain their performance and longevity.

- Q:How does the use of plastic in home appliances impact the overall weight distribution of the appliance?

- The use of plastic in home appliances generally reduces the overall weight of the appliance. Plastic is a lightweight material compared to other alternatives such as metal or glass. Consequently, incorporating plastic components in home appliances helps to achieve a more balanced weight distribution, making the appliance easier to handle and move around.

1. Manufacturer Overview |

|

|---|---|

| Location | Hebei, China |

| Year Established | 1995 |

| Annual Output Value | Above US$ 50 Million |

| Main Markets | 15.00% Mid East 10.00% Northern Europe 10.00% North America 30.00% Eastern Asia 10.00% Africa 9.00% Eastern Europe 8.00% Southeast Asia 3.00% Oceania 3.00% Western Europe 2.00% Southern Europe |

| Company Certifications | ISO 9001 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; Qingdao; Shagnhai; Guanghzou |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese |

| b)Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 5 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

PVC Strip Door Curtain Used for Food Factory

- Loading Port:

- TianJin

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 50 Rolls roll

- Supply Capability:

- 15 Containers Per Month roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products