PVC Stabalizer For Plastic Profile,Rubber

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of PVC Stabalizer

Classification: Chemical Auxiliary Agent

Other Names: one pack pvc stabilizer

Purity: 99.9%

Place of Origin: Shandong, China (Mainland)

Type: PVC Stabilizer

Usage: Plastic Auxiliary Agents

Brand Name: HaoMing

Model Number: Pipe Grade

2. Main Features of the Calcium Pvc Compound Stabilizer

Product

PVC stabilizer, Also called One pack pvc stabilizer

Description

It is lead based compound stabilizer containing internal and external lubricants.

It is used for producing pvc pipes. It has excellent processing performance

for calendaring molding. It will not effect the flatness, bright and clean,

even thickness of the product when the filling material has a fluctuation.

Specification

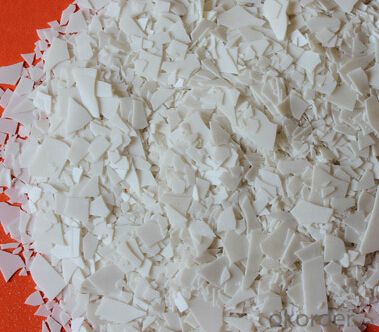

1. Appearance: white flake

2. Lead oxide content,%: 30-40

3. Melting Point:70min

4. Moisture,%:0.5max

Addition quantity

According to the different equipments of calendars, suggests add 3-4 phr in each 100 phr PVC resin.

3. Images Of PVC Stabalizer

4. PVC Stabalizer Specifications

1. Appearance: white flake

2. Lead oxide content,%: 30-40

3. Melting Point:70min

4. Moisture,%:0.5max

5. FAQ of Calcium Pvc Stabilizer

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand

- Q:Is the catalyst in the chemical reaction better?

- No, you can. Too much useless

- Q:What is the principle of catalyst reaction rate in chemical reactions?

- Can significantly change the reaction rate and its own chemical properties and quantity in the reaction before and after the basic material unchanged. The catalyst has a positive catalyst (i.e., accelerates the reaction rate) and a negative catalyst (i.e., reduces the reaction rate), and generally does not specifically refer to both the positive catalyst.

- Q:Chemical equation if there is a catalyst and heating, which write in the equal sign above, which written in the following? Tomorrow academic level test, solution

- At the same time, the catalyst is written on, and the heating symbol is written under the equal sign. Only one is written on the equal sign

- Q:Especially how can i explain the experiment with a paper and 2 paperclips with the paper acting as the catalyst.

- A catalyst is something that allows a reaction to occur but is not actually used up in the reaction. It merely provides the surface on which the chemicals react. There is a demo using two paper clips and a piece of paper. The paper is folded and the two clips are attached to the paper. When the free ends of the paper are pulled apart the two paper clips somehow overlap each other and become joined. It is a good demo for a catalyst, but I cannot explain how to fold the paper.

- Q:Several experiments were carried out using catalysts

- Hydrogen peroxide in the manganese dioxide as a catalyst for decomposition reaction: 2H2O2 == MnO2 == 2H2O + O2 ↑ (laboratory oxygen principle)

- Q:Does the catalyst participate in chemical reactions?

- The catalyst does not participate in the chemical reaction, it only plays an auxiliary role.

- Q:High chemistry: Does the catalyst affect the heat and heat of the reaction?

- No effect

- Q:Organic chemical concentration of bromine and liquid bromine What is the difference between the conditions in the iron as a catalyst can not be reacted with toluene to produce tribromotoluene? Is it possible to work with phenol to produce tribromophenol?

- The concentrated bromine water is a bromine aqueous solution and the liquid bromine is pure bromine. Only liquid bromine can produce tribromotoluene, and to add iron powder as a catalyst, and the main production is to lead bromotoluene and p-bromotoluene, tribromotoluene this content is very small.

- Q:What is the standard for the storage of flammable and explosive chemicals now?

- First, the basic requirements of classification of storage Dangerous goods, variety, complex performance, storage, in accordance with the zoning, classification, sub-section of the principle of special storage, set the number, set the number of fixed warehouses, fixed staff (four) custody. Small warehouses should be classified, divided, sub-stack storage, the performance of each other, fire fighting different items, dangerous dangerous goods and other general dangerous goods, should be stored separately.

- Q:Does all chemical reactions have a catalyst?

- Not some reaction without catalyst

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Stabalizer For Plastic Profile,Rubber

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products