pvc sponge flooring Manufactory price Hot Sales indoor 20years history

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Specifications

W/L: 0.5mm

Surface: Crystal Texture

Vinyl Plank

UV matt

Size: 1227*157*3.0mm

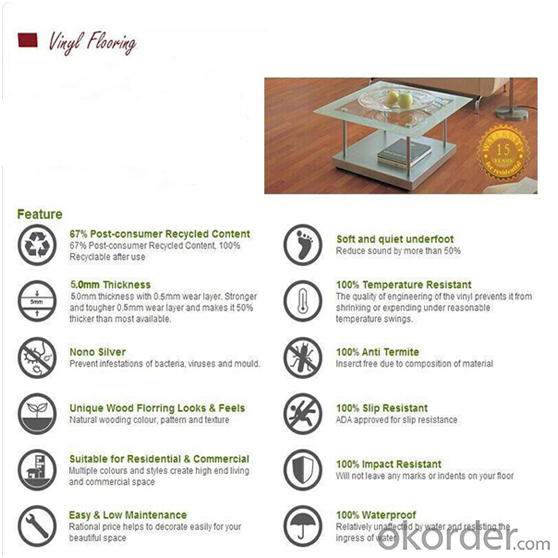

Name | 3mm Dark Limed Grey Oak Crystal Texture Vinyl Floor Colorful PVC Vinyl Flooring |

Color | We have several hundreds of colors to customers' option |

Thickness | 2mm, 2.5mm, 3.0mm, 4.2mm, 5.0mm are available |

Surface | More than 6 kinds of surfaces,such as Registered in Emboss, Antique Wood Texture, Crystal Texture, Pearl Structure, Carpenter Handscrape, Classic Slate and etc. |

Size | Different kinds of sizes to satisfy you |

Other Procedures | We provide PVC sheet making, Hot pressing, UV-coating, Annealing, Punching and Profiling, etc. |

Service | Perfect Quality Control System,VIP server solve your problem in time |

Innovation | R&D team develop new product or color weekly |

Payment | 30% deposit and 70% upon the copy of B/L |

Delivery Time | Within 40 days after receipt of your L/C from your bank or receiving the deposit |

Why Choose Us

1. 15-Year professional experience in CNBM Flooring.

2. The Fastest Delivery Speed

3. Excellent After-sales Service

Technical Data

Safety Criteria | Standard | Value |

Flammability | EN 13501-1 | Bf1 |

Slip resistance | EN13893 | DS |

Formldehyde Emission | EN717-1 | None |

Color Fastness | ISO 105-BO2 | ≥ 6 |

Castor Wheel Test | EN425 | Pass |

- Q:How long can be used for plastic floor restaurant

- Commercial flooring / plastic flooring1, commercial floor material PVC (real name: PVC floor)2, commercial floor PVC wood material3, commercial floor uses: kindergarten, office, stairs, family, factory, school, hotel, hotel4, life: 6 years to more than 15 years5, thickness: 2 mm6, color: more than 207, size: 20 meters long, width of 1.8 meters, 2 meters8, suppliers: Shanghai, Shanghai and the United States floor9, price: different thickness, different grades, different PVC content, different prices.10: Shanghai, the United States and the United States commercial floor price of 2 mm to 50 yuan per square meter installation price11, place: gray, wood12, family selection: red, blue, black, wood13, kindergarten; pink, green, yellow

- Q:The plastic floor gives off a plastic smell. Is it harmful?

- PVC floor compared with various floors: PVC of linseed oil: linseed oil: linseed oil, a mixture of cork and wood, laminated to jute backing. Also... Add other unnatural chemicals. Scratch resistant, hard and soft linseed oil. This is why the poor performance of thick linseed oil. The dimensional stability of linseed oil is poor

- Q:What plastic floor

- Light weight: weight after construction. After the construction of lightweight wooden floors than 10 times than the ceramic tile construction light weight 20 times than stone construction after 25 times of light weight, the utility most suitable for high buildings, three floors above the office building etc.. Reduce the bearing capacity of the building, safe, and convenient handling.

- Q:Composite floor plastic sheeting down the impact of heat

- It should be paved, but it's not a plastic cloth

- Q:The family is decorated with the plastic corrugated pipe buried in the floor tiles under the good?

- However, we should pay attention to the slot, do not hurt the water pipes or heating pipes, generally in others, will pop up on the ground line, indicating that the line has a pipeline. Another reminder, when it is best to use marble carved slot machine cut out of the groove, and then tick chisel. Now there are often no construction personnel in accordance with the provisions of the operation, resulting in damage to the ground or wall.

- Q:PVC plastic floor can be used as a kitchen operating room, right?

- Seems to be floor paint How do I know what it is?

- Q:How to remove the plastic protective film on the floor angle

- There are three kinds of brick protective film:plastic filmBe able to gradually tear with the hand or be able to gently wipe with a steel ball.Antifouling protective filmThe protective film can be dipped in white cement with a towel.Ceramic tile protective filmBe able to scrub with a dry towel, scrub with an electric thinner or banana, and also use talcum powder and white cement.

- Q:Wood floor moistureproof can use plastic film?

- The thickness swelling rate of water absorption is far less than the national standard. In addition, the special wear-resistant layer, decorative paper, the balance layer, can be a good substrate "closed" to ensure that the overall moisture-proof floor better

- Q:Shop: composite floor below the moisture with plastic mold moisture do?

- Composite floor installation suspension installation: the first is the glue. The quality of the glue determines the quality of the floor, but also directly related to the length of service life.

- Q:Water general plastic floor glue harmful to the human body

- The production process of domestic PVC sheet flooring is not mature, the compound PVC sheet flooring is a multilayer structure, domestic PVC manufacturers mostly use sheet flooring glue adhesive, in addition PVC production technology is not mature, especially in the use of additives, so the domestic PVC sheet flooring contain serious odor, the smell of formaldehyde gas

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

pvc sponge flooring Manufactory price Hot Sales indoor 20years history

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 80000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords