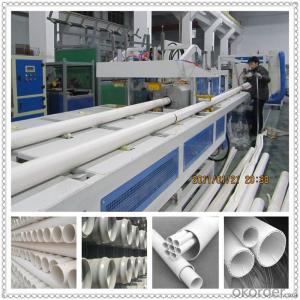

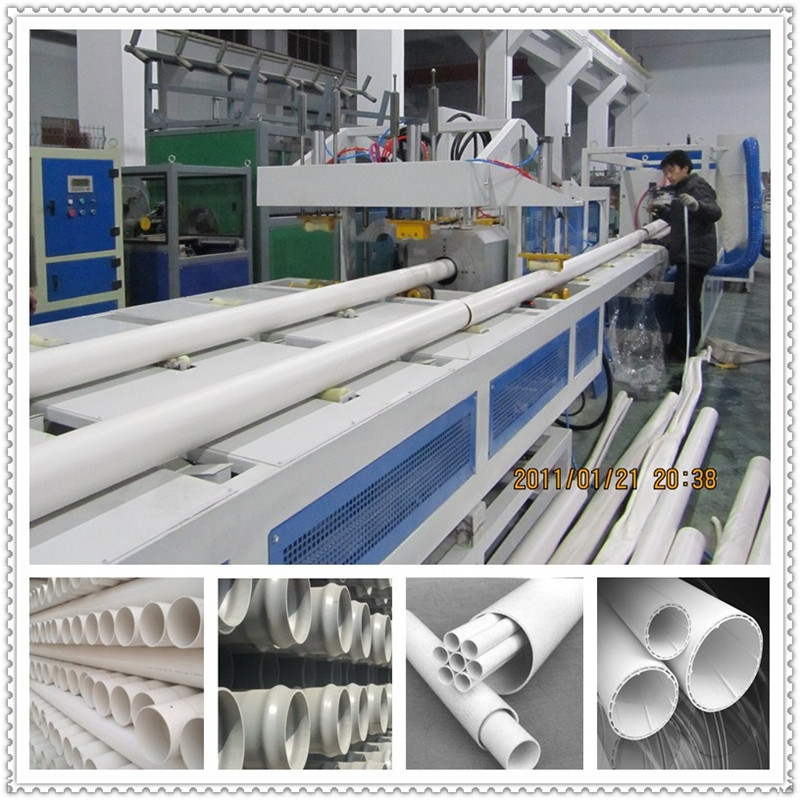

PVC small pipe making machine wire conduit pipe extruder machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

New high output PVC small pipe machine wire conduit pipe making machine Double pipe production line PVC two pipe extrusion line PVC wire pipe extruder machine

The production line is development with the advanced technology of West Europe by our company. The main machine is SJSZ-51 or SJSZ-65 conical twin screw extruder is equipped with double-tube separate-control stainless steel spraying calibration.It avoids waste condition when one tube is adjusted and the other one is affected.

Small PVC wire pipe machine Production Line details:

1.AC motor,ABB frequency speed governor, Japanese RKC temperature controller, Schneider contactor.

2.Screw Nitriding treatment,hardness HV740-940,surface roughness Ra≤ 0.8um.

3.Barrel air-cooled cooling method, nitriding depth of 0.5- 0.7mm, hardness of HV860 or more, the surface roughness Ra ≤ 1.6um.

4.Die head material,High quality steel by quenching and tempering.Structure,Where contact with the materials hard chrome plating.Bolts level,12.9 high strength bolts.

5.Two Vacuum calibration tank material:Stainless steel.

6.Double Caterpillar adjusting method: pneumatic compress device.

7.Double cutter: Most cutting times,20 times/min;With strong waste clean device. Equipped with a meter installation, meter size is accurate.

8.Double stacker: Pneumatic flip, soft rubber, to prevent pipe surface scratch.

9.All electrical parts adopt world famous brand product.

Extruder For PVC small diameter conduit Pipe machine :

| Item | SJSZ-51 | SJSZ-65 |

| Diameter of screw(mm) | 51/105 | 65/132 |

| Screw rotation speed(rpm) | 1-45 | 1-35 |

| Power of Main engine(kw) | 18.5 | 37 |

| Production capacity(kg/h) | 80-150 | 250-300 |

| Net weight(kg) | 3200 | 4000 |

| Dimensions(mm)(L*W*H) | 3600*1100*2100 | 4235*1520*2450 |

We are the manufacturer specialized in plastic machine manufacture for many years,our products are exported to many countries.If you are interested in our products,please contact us at any time.

- Q:Cable extruder how to match the mold, how to calculate the formula, ask the master pointing

- Look at what you have in the form of mold, extrusion, drawing, or half pipe

- Q:What is the temperature setting of the extruder and how much is the setting temperature of the head and filter?,

- The temperature setting of the extruder is related to the material you manufacture. If the type of plastic is different, the setting temperature is different, and the material of different manufacturers is also slightly different from the temperature setting.

- Q:Is the extruder the same as the extruder?

- The extruder is also called in the screw extruder is under the action of the molten plastic extrusion through fixed shape extrusion, water cooling after cutting in the traction machine under the same section is mainly used for a variety of products.

- Q:Why will the extruder frequency shift stop?

- Because the frequency converter is out of order, you can look at the fault record parameters of the inverter.

- Q:What is an extruder?

- Usually called extruder, it is a plastic extrusion machine.

- Q:Extrusion blow molding machine, storage or continuous type good?

- The amount of extrusion must be continuous, efficient, and wasteful

- Q:why production is not strong?I have several new co extrusion machines, but the blown plastic bags are not produced by others

- Tensile strength is divided between longitudinal and transverse, and PE bags are transversely increased, available 8CLLDPE is added, longitudinal can be added to medium, medium density or high-density material to increase tensile strength.

- Q:Basic parameters of extruder screw

- 2. The ratio of the length to diameter of the screw, the length of the screw L/Ds and the ratio of L to the diameter of the screw Ds is called the ratio of length to diameter. When the other conditions are constant (such as the diameter of the screw), increasing the ratio of length to diameter means increasing the length of the screw. The L/Ds value is large and the temperature distribution is reasonable, which is beneficial to the mixing and plasticizing of plastics. At the same time, the heating time of the plastic in the barrel is longer, and the plasticization of the plastic will be sufficient and more uniform. So as to improve the quality of machine plastics. If the plastic quality requirement is constant, the rotation speed of the screw can be increased after the ratio of length to diameter increases, thereby increasing the extrusion amount of the plastic. However, too large length diameter ratio, power consumption will increase the screw, and the screw and barrel of the processing and assembly of chicken more difficult; the possibility of screw bending will increase, will cause the abrasion of the screw and the inner wall of the cylinder, reduce the service life. In addition, the heat sensitive plastic, large diameter and long retention time than thermal decomposition, the plasticizing and impact plastic extrusion quality. Therefore, in the full use of the advantages of increasing the ratio of length to diameter, the selection should be based on the physical properties of the processed plastics and the quality requirements of the products.

- Q:There is a 90 extrusion machine, used in the production of communication cables (outside the cable core is extruded with a layer of LLDPE), now is the configuration of Y2-280M-490KW167A inverter type ACS510197A + ABB), General Motors now found low speed when the current is too large, what reason? How to solve? The details are as follows: used for communication cable production HYA30*2*0.4, 1, line speed is 50 m / min, inverter display frequency 35.3HZ current: 116A; 2, line speed is 40 m / min, inverter display frequency of 28.2hz, current: 140A3, line speed is 35 m / min, the frequency converter significantly method: 157A 24.6HZ frequency current, because the product variety and technical reasons, we need to be in the frequency of 10HZ production. Now, it seems that if I reduce the speed again, the current will probably exceed the rated current. What should I do? Is the motor changed to frequency conversion motor? Or inverter? How to solve? Please heroes pointing, thank you!

- Fan, water pump at low speed, torque is not enough, resulting in high current, if vector control can be ideal.

- Q:Ask everyone about the extrusion machine at the wire factory...... How do you adjust the speed of the motor?

- The outer diameter is big...... I've got the tractor switched 1600 and the engine is switched 1400Chasing the answerThe extruding worker sees the line, cannot see the speed meter, the speed meter sometimes is not allowedLarge diameter, you can reduce the speed of the main engine or speed up the traction, in addition, the maximum current of the host can not exceed 2 times the power rating of the motor, more than two times will burn the motor.AskI've finished pulling the button.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC small pipe making machine wire conduit pipe extruder machine

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords