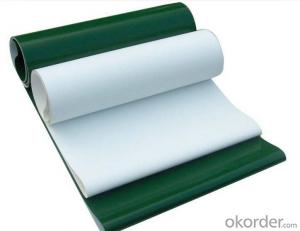

PVC/PU Food Conveyor Belt White Green Color Belt

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC/PU Food Conveyor Belt White Green Color Belt

Description

This light-duty conveyor belt takes braided fabric made of polyester threads that

has undergone special technical treatment as the carrier framework. One or both

sides are coated with rubber, PVC, PU or PE. It features great strength, little

elongation or extension, good bending and twisting ability, stable running, and

long service life.

PU conveyor belt has the common traits of high tensile strength, good bending, lightness,

thinness and toughness. It also has the outstanding traits of anti-germ,

wear-resistance, oil-resistance, nonpoisonous and sanitary, and easy to clean.

All of these conform to the management requirement of conveying non-packed food.

PE conveyor belt has the common traits of high tensile strength, good bending, and

stable running. It is also nonpoisonous and sanitary, easy to clean, and has smooth

surface. It can touch with food directly. It is the ideal matching equipment of deep-processing industry for tobacco, food, meat and fishery, fruit and vegetable.

Applications

Widely used in food industry. Transport the material in bulk, canning and packed In box. The material includes grain, cooky, candy, vegetables, fruit, fowl, meat and so on.

Also widely used in soft material industry. Used in those field, including tobacco, electron, textile, printing and dyeing, machine manufacturing, print and package, paper processing, pottery, marble, wood processing,car shell molding, cable fishing wire, aluminium parts processing and etc.

Product pictures:

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q:Can olive nets be used for olive tree air circulation management?

- No, olive nets are primarily used for harvesting olives and protecting them from pests, rather than for managing air circulation around the olive trees.

- Q:Can olive nets be used for olive trees in urban settings?

- Yes, olive nets can be used for olive trees in urban settings. Olive nets are commonly used in olive tree cultivation to protect the ripening olives from birds and other pests. Urban settings often have a higher bird population, making olive nets even more crucial in these areas to ensure a successful harvest.

- Q:Can olive nets be used for olive tree protection from extreme temperatures?

- Yes, olive nets can be used for olive tree protection from extreme temperatures. These nets help create a microclimate around the trees by providing shade during hot weather and retaining heat during cold weather, thus protecting the olive trees from extreme temperatures.

- Q:Can olive nets be used on olive bonsai trees?

- Yes, olive nets can be used on olive bonsai trees to protect the fruits from birds and other animals.

- Q:What glue is best for sticking glue?

- Determination of the above requirements of choice such as small area bonding glue is generally used, quick drying glue, is instant glue, together with surface treatment agent PP/PE/POM for use. The first treating agent for cleaning the surface, you can achieve a good bonding effect. Of course, the cost is not low. But super adhesive the adhesive surface damage to. Recommended adhesive: ABS material can be used ABS special glue HR-700, PP, PE, PA material availablePP, PE sleeve special glue HR-736

- Q:Can olive nets withstand harsh weather conditions?

- Yes, olive nets are designed to withstand harsh weather conditions. They are made from durable materials that are resistant to wind, rain, and other weather elements, ensuring their longevity and effectiveness in protecting olive trees.

- Q:Can olive nets be used in olive tree nurseries?

- Yes, olive nets can be used in olive tree nurseries. Olive nets are commonly used in nurseries to protect the young olive trees from pests, animals, and harsh weather conditions. These nets help create a controlled environment that promotes healthy growth and development of the olive trees.

- Q:Are olive nets suitable for olive tree nurseries?

- Yes, olive nets are suitable for olive tree nurseries. These nets provide protection from pests, birds, and excessive sunlight, creating a favorable environment for the healthy growth of olive trees in nurseries.

- Q:Are olive nets easy to clean?

- Yes, olive nets are generally easy to clean. They can be easily washed with water and mild detergent to remove any debris or dirt that may have accumulated during olive harvesting.

- Q:Can olive nets be used for both small and large-scale olive tree transplanting?

- Yes, olive nets can be used for both small and large-scale olive tree transplanting. Olive nets are versatile and can be adjusted to accommodate different sizes of olive trees. They provide protection to the tree during the transplanting process, preventing damage to the branches and leaves. Additionally, olive nets help retain moisture around the roots, promoting successful transplantation and establishment of the tree in its new location.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC/PU Food Conveyor Belt White Green Color Belt

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 5000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords