PVC/PU Conveyor Belt with Sidewall Cleats and Guide for Light Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

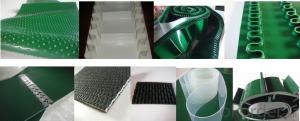

PVC/PU Conveyor Belt with Sidewall Cleats and Guide for Light Industry

PVC/PU Conveyor Belt

Light duty conveyor belts are manufactured for all applications with various fabrics impregnation like polyester, nylon, cotton, solid woven, fiberglass etc. Belts are available in different colors like green, white, black, blue and thickness from 0.5 mm to 15 mm up to 3500 mm width and with top surface coating Rubber, PVC, PU, TPU, PE, TPEE, Teflon, Silicone, etc.

Colors: red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness: PVC (1~7mm) PU (0.8~4mm)

Appearance: flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages: PVC: economical and practical, technology is mature.

PU: applicable to the food industry, abrasion resistant and corrosion.

Subsequent machining technology: it can add baffle, skirt, sponge, guide bar.

ADVANTAGES:

Low operating noise and costs, reduced maintenance, excellent durability.

Largely impervious to oils, greases and many chemicals.

Special types give excellent grip on inclination.

Abrasion resistant - rugged, high strength - low stretch characteristic.

Light and thin, better strength / weight ratio - energy saving.

Superb tracking over great length - longitudinally flexible and laterally stiff.

Please contact us freely if you need any conveyor belt.

- Q:Can I marinate salted eggs with a plastic bucket?

- In addition, PVC plastic products at higher temperatures, such as 50 degrees or so, will slowly decompose hydrogen chloride gas, this gas harmful to humans, so PVC products should not be used as food packaging. Bakelite (bakelite) containing phenol and formaldehyde, have certain toxicity to the human body, is not suitable for the storage of food and food packaging. Electric jade (urine aldehyde plastic) although odorless, but at 100 degrees of boiling water or vinegar for containing food, there will be precipitation of free formaldehyde, harmful to the human body, so it is not suitable for food or food packaging. Waste plastics (some may add a little new material) update, because of its complex composition, it is difficult to guarantee that no toxicity, it is generally not used as food containers and packaging.

- Q:How to make plastic shrink?

- The shrinkage of plastic is the percentage of the size of the plastic parts at the molding temperature and the size of the mold after being removed from the mold and cooled to room temperature. It reflects the extent to which plastic parts are removed from the mold and cooled to a reduced size.

- Q:Can olive nets be used in regions with limited access to machinery for mechanical harvesting?

- Yes, olive nets can be used in regions with limited access to machinery for mechanical harvesting. Olive nets are a traditional method of harvesting olives that does not require machinery. They involve spreading nets under the olive trees to collect the fallen olives when they are manually shaken or knocked off the branches. This method is commonly used in areas where mechanical harvesting equipment is not available or feasible due to limited resources or difficult terrains.

- Q:What is the most effective way to reduce the environmental pollution caused by plastic bags?

- White pollution is one of the plastic packages that are difficult to degrade. Disposable foam tableware such as fast and we used plastic bags and so on. It is very serious environmental pollution, buried in the soil is difficult to decompose, the soil will lead to reduced capacity, if the burning causes air pollution, so I do not advocate or less with it, buy the best own tools to reduce its use.

- Q:How do olive nets prevent olives from bruising?

- Olive nets prevent olives from bruising by creating a protective barrier between the olives and the ground. The nets catch the olives as they fall from the tree, preventing them from making direct contact with the hard surface. This reduces the chances of bruising and damage to the olives, ensuring a higher quality yield.

- Q:Can olive nets be used in hot climates?

- Yes, olive nets can be used in hot climates. Olive nets are commonly used in regions with hot climates to protect the olive trees and collect the fallen olives during the harvesting season. The nets help shade the trees and prevent the olives from direct exposure to the scorching sun, which can improve the quality of the olives and prevent damage from excessive heat.

- Q:How do you understand the level of engineering plastics?

- 1, PET (polyethylene terephthalate): at present, the general mineral water, carbonated drinks and functional beverage bottles are used in this material. Heat resistant to 70 degrees, easy to deformation.

- Q:Can olive nets be used in olive tree nurseries?

- Yes, olive nets can be used in olive tree nurseries. Olive nets are commonly used in nurseries to protect the young olive trees from pests, animals, and harsh weather conditions. These nets help create a controlled environment that promotes healthy growth and development of the olive trees.

- Q:How do olive nets prevent olives from being damaged by rain?

- Olive nets prevent olives from being damaged by rain by providing a protective barrier over the olive trees. The nets act as a shield, preventing rainwater from directly hitting the olives and causing damage such as rot or splitting. Additionally, the nets also serve to minimize the impact of heavy rainfall on the soil, preventing erosion and creating a more stable environment for the olive trees.

- Q:Can olive nets be used for both traditional and hydroponic olive tree harvesting?

- Yes, olive nets can be used for both traditional and hydroponic olive tree harvesting. Olive nets are commonly used in traditional harvesting methods to catch the olives as they are manually picked from the trees. In hydroponic systems, where olive trees are grown without soil, nets can also be used to collect the olives when they are ready for harvest.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC/PU Conveyor Belt with Sidewall Cleats and Guide for Light Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords