PVC/PU Conveyor Belt Used in Light Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

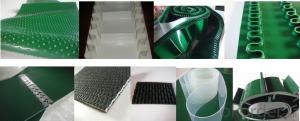

PVC/PU Conveyor Belt Used in Light Industry

PVC/PU Conveyor Belt

Light duty conveyor belts are manufactured for all applications with various fabrics impregnation like polyester, nylon, cotton, solid woven, fiberglass etc. Belts are available in different colors like green, white, black, blue and thickness from 0.5 mm to 15 mm up to 3500 mm width and with top surface coating Rubber, PVC, PU, TPU, PE, TPEE, Teflon, Silicone, etc.

Colors: red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness: PVC (1~7mm) PU (0.8~4mm)

Appearance: flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages: PVC: economical and practical, technology is mature.

PU: applicable to the food industry, abrasion resistant and corrosion.

Subsequent machining technology: it can add baffle, skirt, sponge, guide bar.

ADVANTAGES:

Low operating noise and costs, reduced maintenance, excellent durability.

Largely impervious to oils, greases and many chemicals.

Special types give excellent grip on inclination.

Abrasion resistant - rugged, high strength - low stretch characteristic.

Light and thin, better strength / weight ratio - energy saving.

Superb tracking over great length - longitudinally flexible and laterally stiff.

Product Feature

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise (LdB belts)

* Working temperature ranges from -10 to 80Deg.C

Please contact us freely if you need any conveyor belt.

- Q:Do olive nets prevent olives from being blown away by strong winds?

- Yes, olive nets are designed to prevent olives from being blown away by strong winds.

- Q:How do olive nets prevent fruit predation by insects?

- Olive nets prevent fruit predation by insects by acting as a physical barrier that prevents insects from reaching and feeding on the olives. The nets are placed over the olive trees, creating a protective shield that keeps insects away from the fruit. This helps to maintain the quality and quantity of the olive crop, as it reduces the damage caused by insect pests.

- Q:Can olive nets be used to increase yield?

- Yes, olive nets can be used to increase yield. By placing nets under olive trees, they help catch falling olives during harvesting, reducing fruit loss and increasing overall yield. The nets also provide shade, preventing sunburn on the fruit and improving their quality. Additionally, nets can protect the olives from birds and other pests, further enhancing the yield.

- Q:How do olive nets prevent rodent damage to olives?

- Olive nets prevent rodent damage to olives by creating a physical barrier that prevents rodents from accessing the trees and feasting on the fruit. The nets are securely placed over the olive trees, covering the entire canopy and preventing rodents from climbing up or jumping onto the branches. This effectively keeps the olives safe from rodent infestation and preserves the quality and quantity of the harvest.

- Q:Can olive nets be used in combination with automated irrigation systems?

- Yes, olive nets can be used in combination with automated irrigation systems. Olive nets are primarily used to collect olives during harvest, but they can also serve as a protective barrier to prevent evaporation and retain moisture in the soil. By utilizing automated irrigation systems, water can be delivered efficiently to the olive trees, ensuring they receive the necessary moisture for optimal growth and yield while the nets remain in place.

- Q:Can olive nets be used in both traditional and modern olive farming practices?

- Yes, olive nets can be used in both traditional and modern olive farming practices. Olive nets are commonly used to protect the olives from birds, reduce fruit loss, and ease the harvesting process. Whether in traditional farming where manual labor is involved or in modern practices that may incorporate machinery, olive nets are a versatile tool that can be utilized effectively in both farming methods.

- Q:Can olive nets be custom-made?

- Yes, olive nets can be custom-made to fit specific dimensions and requirements.

- Q:Can olive nets be customized?

- Yes, olive nets can be customized to fit specific requirements and dimensions.

- Q:How can a plastic foam be used?

- If you have a plaid or a unique plastic foam package, you can dye it and fix it on the wall to make it an abstract decoration. It is economical, affordable and creative. I believe it is absolutely unique! If the lattice space space, can also receive some lighter some items, such as scarves, neckties, neckties, thin gloves, hairpin, headwear and so on, readily available small objects.

- Q:Can olive nets be used in regions with high disease pressure?

- Yes, olive nets can be used in regions with high disease pressure. Olive nets provide physical protection to the olive trees, preventing direct contact of the fruit with pathogens or pests. However, it is important to note that while olive nets can offer some level of protection, they should be used in conjunction with other disease management practices such as regular monitoring, proper sanitation, and the use of appropriate pesticides or fungicides to effectively combat diseases in high-pressure regions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC/PU Conveyor Belt Used in Light Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords