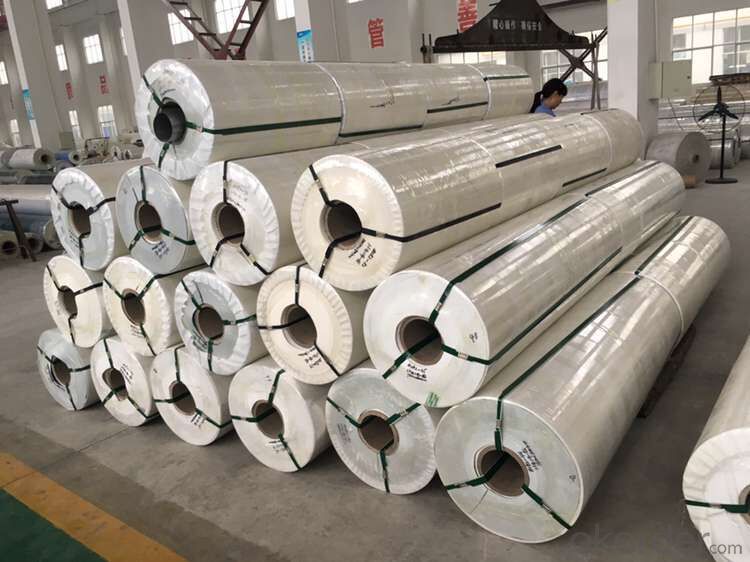

PVC/PU Conveyor Belt Round Dot Rough Top Surface

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC/PU Conveyor Belt Round Dot Rough Top Surface

Conveyor belt fabric layers:

A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

Colors:

Red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness:

PVC (1~7mm) PU (0.8~4mm)

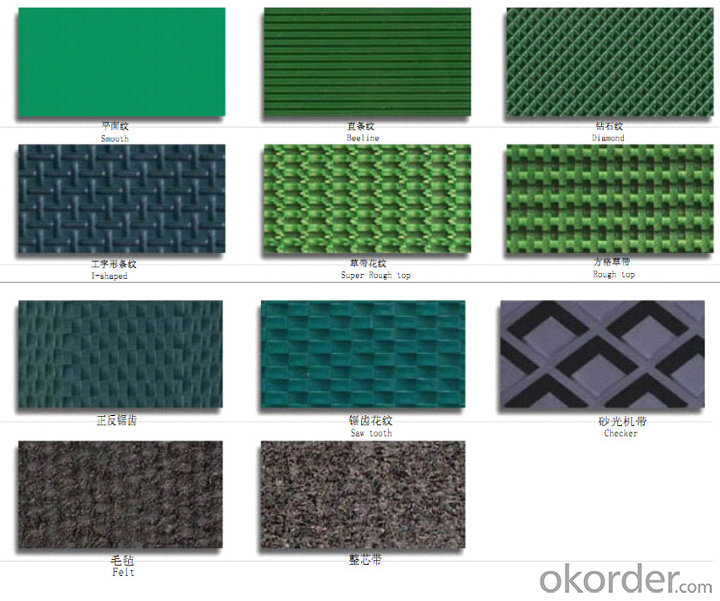

Appearance:

flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages:

PVC: economical and practical, technology is mature. Non-toxic, odorless, environmentally friendly.

PU: abrasion resistant and corrosion.

Application:

PVC: Food, medicine, electronics, tobacco, printing, packaging, textile and other production lines belt.

PU: Most applicable to the food industry and other industries .

Subsequent machining technology:

it can add baffle, skirt, sponge, guide bar and etc.

PVC light industry conveyor belt

Suitable for light industrial, packing light industrial, transport for tobacco, tea, pieces vegetable, fruit and so on. Also can be used in airport, post office, storage and etc.

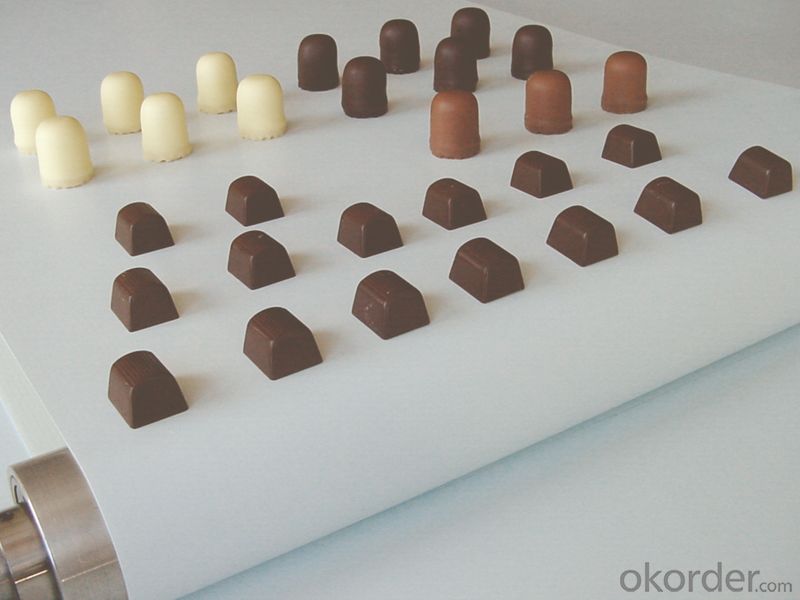

PU light industry conveyor belt

Widely used in food industry. Transport the material in bulk, canning and packed In box. The material includes grain, cooky, candy, vegetables, fruit, fowl, meat and so on.

Also widely used in soft material industry. Used in those field, including tobacco, electron, textile, printing and dyeing, machine manufacturing, print and package, paper processing, pottery, marble, wood processing,car shell molding, cable fishing wire, aluminium parts processing and etc.

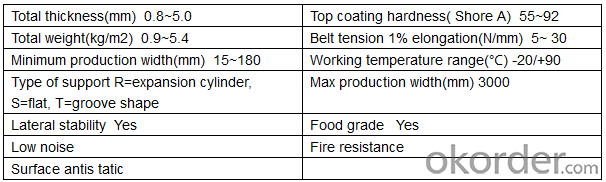

PVC Conveyor Belt Specification

Photos of Food PVC Conveyor Belt

FAQ

Can you give me discount?

Yes, of course. If you talk with us, you’ll get more.

Will you send me free sample?

Yeah, she'd love to; can you buy her a ticket?

Do you like to accept small orders?

We enjoy to grow up together with all our clients, whatever big or small.You will become bigger and bigger to be with us.

Buyer attention

If you are interested in our products and company, please leave a message here or E-mail to us, We will reply you without any delay.

- Q:Are there any specific guidelines for storing olive nets during the off-season?

- Yes, there are specific guidelines for storing olive nets during the off-season. It is recommended to clean and dry the nets thoroughly before storage to prevent mold or mildew growth. Store the nets in a dry and well-ventilated area, preferably in a covered space to protect them from direct sunlight or extreme weather conditions. Additionally, it is advised to fold or roll the nets properly to minimize creases and ensure easy handling when they are needed again.

- Q:What's the difference between memory plastic and sheet metal?

- Ingredients: most of the ingredients are acetate fibers, and a few high-grade frames are fibers of propionic acid. The cellulose fiber sheet is divided into injection molding and compression grinding type, injection molding, as the name suggests, is watered by the mold, but most of the current press polishing processing plate glasses. On the origin of the plate, France and Italy plate is better, and Japan is also relatively good, many of the high grade plate glasses are based on these high-quality plates, and therefore more trustworthy quality. Design: designed for the general public and the pursuit of quality of life students tailor-made. Features: simple, introverted design style, the overall show of a sedate side, using the right coloring process. Emphasize stereoscopic changes in the mirror's leg line.

- Q:Can olive nets protect against birds?

- Yes, olive nets can help protect against birds by acting as a physical barrier, preventing them from accessing the olives or other crops.

- Q:Mobile phone shell or other plastic products, the internal screw column thread is injection, or?. After injection processing?

- The internal screw column of a mobile phone shell and other products has smaller diameter, and the screw column thread of the utility model is not molded out by injection, but is processed in the late stage.

- Q:How do olive nets hold up in extreme weather conditions?

- Olive nets are designed to withstand extreme weather conditions. They are typically made from durable materials such as high-density polyethylene (HDPE) that are resistant to tearing, UV radiation, and moisture. These nets are also designed with reinforced edges and strong stitching to ensure they can hold up against strong winds and heavy rainfall. Additionally, some olive nets are treated with additives that provide extra protection against weathering. Overall, olive nets are built to withstand harsh weather and provide reliable protection to olive crops.

- Q:Can olive nets be used in different weather conditions?

- Yes, olive nets can be used in different weather conditions. These nets are designed to protect olive trees and their fruit from various weather elements such as wind, rain, and hail. They are typically made from durable materials that can withstand different weather conditions, ensuring the safety and productivity of olive trees regardless of the weather outside.

- Q:Can olive nets be used in combination with rootstock selection methods?

- Yes, olive nets can be used in combination with rootstock selection methods. The use of olive nets can help protect the trees from pests, birds, and other environmental factors, while rootstock selection methods can ensure optimal growth, disease resistance, and fruit quality. The combination of these two techniques can contribute to a successful olive cultivation.

- Q:How do olive nets prevent damage from fungal infections?

- Olive nets prevent damage from fungal infections by creating a physical barrier that prevents fungi spores from directly coming into contact with the olive fruits. This barrier blocks the entry points for fungal pathogens, reducing the chances of infection and subsequent damage to the olives.

- Q:Do olive nets require any maintenance?

- Yes, olive nets do require maintenance. They need to be regularly checked for any tears or damage and repaired if necessary. Additionally, they should be cleaned and stored properly after each use to ensure their longevity and effectiveness.

- Q:Do all plastic products taste?

- In the life of commonly used plastic polyethylene (used for making plastic wrap, bags, cups, pearl cotton, this is the most secure plastic products, no toxicity); (polyvinyl chloride pipes, packaging bags and other plastic products used in the production of PVC, is not toxic, but is in high temperature or other extreme conditions may release toxic hydrogen chloride);

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC/PU Conveyor Belt Round Dot Rough Top Surface

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords