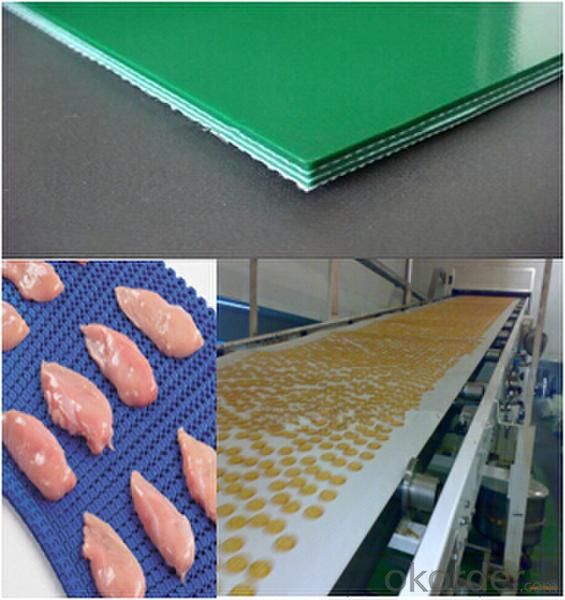

PVC PU Conveyor Belt Light Duty Green White Color Belting for conveyor

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC PU Conveyor Belt Light Duty Green White Color Belting for conveyor

Specifications:

The PVC conveyor belts are manufactured using high quality material.It features largely in the high strength, stable conveyance performance. Besides, it is fire retardant, anti-static, shock resistant, wearable and corrosion resistant. Our food conveyor belts are FDA/USDA approved and most types also have USDA Dairy Approvedand support your HACCP concept.

Features:

1. Non-Conductive

2. Anti-Static

3. Resistant to fats, chemicals, oil fat and abrasion

4. Various surfaces with high, medium and low coefficient friction

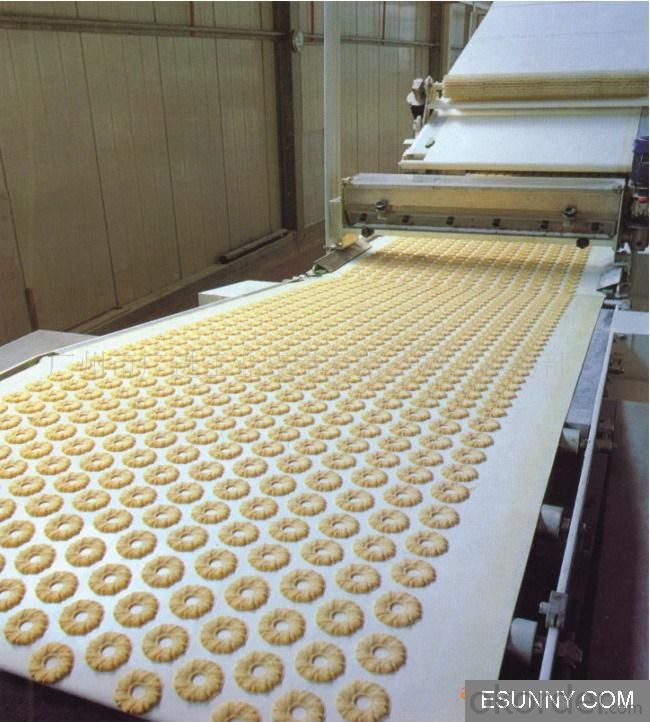

Application:

The belts are bets suited for varied applications like light weight conveyors systems, such as food processing industry, tobacco industry, textial, marble, wood, etc.

We can product various kinds of conveyor, and we also can customize with your requirement

PVC Solid Woven Conveyor Belt:

Ø Suitable for applications in dry conditions at a slope angle of no greater than 16 degrees.

Ø Cover thickness can be from 0.5 to 4mm.

Ø Nitrile covered PVG type

Ø Suitable for applications at a slope angle of less than 20 degrees, thickness can be 1 to 18mm.

Ø Resistance to wetness, slip, low temperature and wear resistance of the belt.

| Specification | Thickness (mm) | Color | Style |

| 1 ply fabric~1 ply p | 1 | green/white | plain |

| 1 ply fabric~2 ply p | 2/3/4/5 | green/white | skirt lace |

| 2 ply fabric~2 ply p | 2/3 | white/B.matt/green | diamond with small dot/grass |

| 2 ply fabric~3 ply p | 3 | green | diamond |

| 3 ply fabric~3 ply p | 4/5/6/7 | white/green matt | network wire |

| 3 ply fabric~4 ply p | 4/5 | green | diamond |

| 4 ply fabric~4 ply p | 9 | green matt | marble |

Above the form just list a part, we can product as your requirement, welcome to negotiate.

- Q:How can the frictional properties of rubber improve?

- Because of its high elasticity and low modulus, the friction and wear properties of rubber are greatly affected by their physical and mechanical properties. The hardness of rubber is smaller, contacting with a rigid object, the real contact area is large, and the real size of the contact area is an important factor, so the friction rubber hardness, have more effect on the friction performance.

- Q:Why should the tire be made of rubber?

- The molecular chain of rubber can be crosslinked, and the crosslinked rubber can recover quickly when it is deformed by external force, and has good physical and mechanical properties and chemical stability. It is widely used in the manufacture of tires, hoses, tapes, cables and other rubber products.

- Q:Aging of rubber parts for automobiles

- The engine bracket, the foot pad, the leaf spring bushing, and the shock absorbing foot cushion, such as rubber aging, will vibrate abnormally and cause abnormal noise, which will cause the damage of the whole component and even the radiation to the surrounding parts. In addition, the rubber bushings on the trucks need to be replaced, it is not an easy task and sometimes requires larger actions. For example, the shock absorber rubber of the cab needs to be lifted if it needs to be replaced.

- Q:How to distinguish between good and bad silicone rubber gasket?

- Silicone products high tear strength anti destruction ability outstanding, long service life, less susceptible to outside interference, the tear strength of silicone products poor general performance gap is easy to appear in the tearing process, so as to force rapid expansion and cracking damage phenomenon.

- Q:How can rubber be made into rubber when it is made?

- Rubber made of rubber products, to be mixed, vulcanized, trimming and many other processes to make rubber products, is a complex processing plant produced.

- Q:What are the application fields of waste tire rubber powder?

- Waste tire rubber powder modified asphalt for highway, waterproofing materials, modified concrete, modified coating, railway sleepers, rubber brick, machine pad, cushion, cushion and other types of subgrade gasket and fenders, sound-absorbing materials, road sealant, shoes, carpet padding, tire pad, car body, bottom sealing rings miscellaneous pieces of rubber, etc..

- Q:Is silicone good or rubber good?

- I don't know. Do you mean the original inorganic silica gel (not rubber) or organic silica gel?. Rubber is especially large, and silicone rubber (organic silica gel) belongs to rubber.

- Q:What is rubber leather?

- High elasticity polymer. The word "rubber" comes from the Indian language "cau-uchu", meaning "weeping tree"". Natural rubber is flowing out from the Hevea latex when tapping after solidification and drying process (see photo). In 1770, British chemist J. Priestley discovered that rubber could be used to erase pencil writing. The material used at that time was called rubber, which has been used so far. The molecular chain of rubber can be crosslinked, and the crosslinked rubber can recover quickly when it is deformed by external force, and has good physical and mechanical properties and chemical stability. Rubber is the basic raw material of rubber industry. It is widely used in making tyres, rubber hoses, tapes, cables and other kinds of rubber products.

- Q:How should the rubber products be dirty?

- Wipe rubber products with a soft cloth. The most important thing is to first rubber products surface adsorption of dirt off, and then in dry, you can.

- Q:Does antirust oil affect rubber?

- Anti rust oil has an effect on rubber, and butadiene rubber is recommended!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC PU Conveyor Belt Light Duty Green White Color Belting for conveyor

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m

- Supply Capability:

- 100000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords