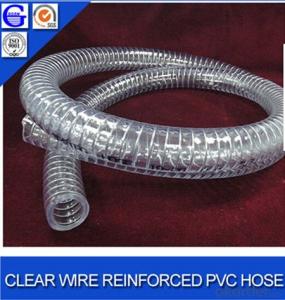

PVC Pipe Food Grade Non-Smell Hose High Pressure

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m

- Supply Capability:

- 5000000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Silicone tube Material: Pure 100% Silicone.

Type: (Solid or Sponge/Foam) Silicone seal strip extrusion; Silicone tube/pipe/cord; Extruded silicone strip.

Size: 1mm to 150mm high and width. Any length. Different sections can as per your sample or drawings.

Color: Translucent, Red, brown. Etc

Temperature: -120-300 degree Celsius.

Tensile strength: 7mpa. Density: 1.25g/cm3. Elongation: 320%.

Grade: Industrial grade; FDA/Medical grade; SGS approval

Special anti-static, anti-acid silicone sheet;

Package: Packaged by plastic film or weaver bags( P. P bags), and pallet OR BOX for export transport.

SPECIFICATION

Rubber Insulation Pipe

Silicone is a low and high temperature resistant rubber (can be formulated to withstand temperatures as low as -118 C and as high as +316 C). It is non-staining, odourless, tasteless and generally inert and is widely used in medical and food applications.

Coupled with these features the material shows excellent resistance to many chemicals, weathering, oxidation and liquid immersion (very low water absorption) along with excellent thermal and electrical resistant qualities.

Silicone hose

1.Material:100% food grade Silicone hose

2.Hardness: 30~90 Shore A

3.PAHS,REACH,FDA approved

4.Flexible,Durble

Additional information

Silicone hoses are used in multiple industrial uses. These tubes are designed to meet the specific client requirements. Our products are high temperature resistance and offer resistance to oil, fuels, acids and lubricants. These also exhibit extreme resistance to corrosive fluids, atmospheric oxidation, sun, weather, fungus and molds. These are low permeable and resist most of the aliphatic and aromatic hydrocarbon.

Our product has a excellent compression set and resists degradation from 300 fluids. These also exhibit higher mechanical and electrical properties. Our products are widely used in chemical, pharmaceutical and automobile industries.

OEM or ODM order are welcomed.

Features

1. Material: FDA Silicone hose.

2. Hardness: 30 to 90 shore A, tolerance can be ±5 shore A, for special products, The tolerance could be reached:±3 shore A.

3. FDA, REACH, PAHS Compliant.

4. Character: Ozone resistant, Oil resistant, Flexibility resistant, Abrasion resistant, sun & weather resistant, Low & high temperature resistant and Non-poisonous.

5. Operating temperature: -70 to +220°C.

6. Out diameters range of 3mm~20mm, Wall thicknesses starting from 0.25mm.

Our Service

We can offer OEM Services

We can provide FREE SAMPPLE for our customers

We can crimp hose assembly for our customers.

We welcome clients to visit our factory leading to better understanding of our production

FAQ

Q1. Do you produce smooth or cloth wrapped cover?

A. Both, we can produce both cover, which depends on customer’s request.

Q2. Do you produce embossed marking?

A. Yes, we do provide embossed and printing markings with different color.

Q3. Can you produce product with my own brand?

A. Yes, we have been offering OEM services for 20 years.

Q4. Does your product have different color hose?

A. Yes, we currently provide black, grey, red, blue and yellow.

Q5. How long does my order take to be delivered?

A. It usually takes 5 to 30 days, which generally depends on the quantity of your order and our storage.

- Q:The maximum number of joints for a rubber hose is no more than

- Hot and cold bath "benefits: first, take a bath with hot water, sweat pores, body dirt with sweat excreted; second, hot water to make the blood flow smoothly, promote the The new supersedes the old. refreshing,; third, for a hot bath and systemic vascular dilatation, and because of cold water bath and contraction. Such a contraction of blood vessels, enhanced flexibility, it is difficult to harden, blood pressure is not high, the old can prevent stroke.

- Q:What kind of material is medical rubber tube?

- PVC, silicone tubes and other medical grade!

- Q:Do you need a hose connection to connect the ventilation pipe to the exhaust fan? Under what circumstances? Under what circumstances?

- Must be added, never heard without the place, the wind turbine operation produces vibration, and galvanized sheet steel pipe is fixed at a certain place, if not, fan vibration, wind pipe vibration, the wind tube life are not long.

- Q:Carbon dioxide gas shielded welding torch wire feed hose joint, that steel wire can not be drawn out, how to solve it, with welding?

- Some of the torch wire feeding hose can not be replaced, it is fixed dead, such as Xiong Gu, Lincoln's self shielded flux cored wire, welding torch.

- Q:Hose connector JB1885-77 what is the standard?

- The pipe joint oil sheet, wool, steel board, combined sealing washer or sealant leak, whatever the material, should first check the seal is damaged, and rough conditions such as deformation, aging, and then take corresponding measures.

- Q:What's the difference between hose and hose for compressed air?

- Generally, they are bundled into difficult to buy, no need to stand upright, probably because I have not seen large caliber. I also think this thing has absolutely nothing to stand up to. You say the hard one is probably covered with rubber and steel ring inside. Generally used to connect peripherals and larger gas equipment. The hoses we call are generally not very rigid. It breaks easily because it is too hard. Use often put hose made of spring shape, prevent the discount of breath

- Q:How to distinguish the true and false corrosion resistant rubber soft joint?

- Put the rubber joint in the corrosive liquid which needs to pass. One day, 24h can see that the swelling ratio is not more than 5%!

- Q:Diameter 127mm steel pipe, and diameter 127mm rubber hose how to connect?

- Connection method:1, send special purchasing rubber pipes, as far as possible to choose the correct tolerance.2, if the work pressure is not more than 0.7MPa, the end of the steel pipe can be in accordance with the rubber tube inside the car, a knife.3, the processing of a casing.

- Q:How about rubber transfusion hose?

- Then the outer layer of glue in the extruder, type coating, and then wrapped with lead or sulfide protective layer can be.

- Q:How can I keep the rubber tube for stethoscope?

- I don't think this question should be considered purely from the point of view of sound transmission.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Pipe Food Grade Non-Smell Hose High Pressure

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m

- Supply Capability:

- 5000000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords