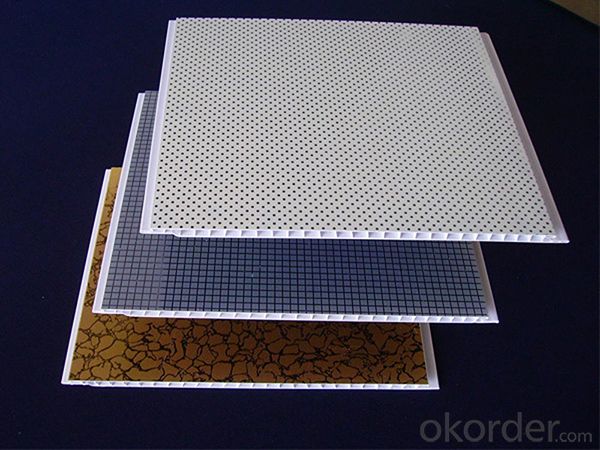

PVC Laminated Panel for Wall and Ceiling

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 550000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Panel Description

Specification

1)Width:100mm,200mm,250mm,300mm,380mm,595mm

2)Thickness:5mm,6mm,7mm,7.5mm,8mm,9mm,10mm

3)PVC content:30%-80%,as your request.

Feature

1,Easy installation ,surface is smoothness ,flatness, without gap when concatenated.

2,It can be processed by drilling ,sawing, nailing.

3,High intensity, high strength, not easy to deformation, resist erosion, sound insulation,

waterproof, fireproof, aging-resisting, durable

4,Interior decoration for ceiling. Easy clearing, heathy and enviroment.

Characteristic of PVC panel:

Fireproof : Self-fire extinguishing, non-flammable , fire and inflaming retardant.

Waterproof (damp-proof): Resistance to weather/ special chemicals; Waterproof / Washable.

Rustproof (resist erosion) : It is impenetrable by insects or termites, and won' t rot or rust.

Heatproof : Good high temperature impact performance .

High intensity : The excellent rigid and superior impacted surface is without any peeling.

Anti aging : Good aging resistance , durable in all mechanical characteristics .

Quality : Hard quality, high intensity and sheen , fadeless , environmental friendly

Design : The variety of colors and patterns .Natural wood (marble) grain: showing authentic wood

Easy setting : Light in weight , the simple and fast installation can save a lot of time and manpower

Other : Easy to be cut, drilled, nailed, sawed, and riveted. DIY is all right;

Quick maintenance and no need of painting;

Good resistance fixations.

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Pictures

- Q:PVC plastic hard board maximum temperature how much

- More than 70 degrees will be deformed, more than 130 degrees will begin to melt ~!

- Q:How heavy the pvc board hangs on the wall

- Pvc board weight is not too large, and only 0.6 square, can be used glass glue pvc board paste to the false wall. First in the pvc board around the diagonal and make a long glass of plastic, and then posted on the wall, surrounded by millet nails or clip fixed, two days after the glass gel dry remove the millet nails or clips can be. Later want to remove the pvc board painting, just use a small blade gently open the viscose of the hole, you can peel down, the wall of the remaining glass glue can also be stripped directly. Are you satisfied with the above?

- Q:PVC trim panel how much money a square meter ah? What brand?

- Now the polymer plate is not a fixed brand, the market too much material, what brand there, but you have to look at the quality to buy, because this material for a long time easy to aging! The general price of 50 dollars or so. However, the market is not the same, the price is not the same. Linyi price is very cheap.

- Q:What models are pvc boards?

- Soft pvc hard pvc polycondensation pvc expansion poly pvc / modified pvc.

- Q:Pvc foam board what materials?

- Product Usage Widely used in passenger cars, train car roof, box core layer, interior decoration board, building exterior panels, interior decoration board, office, residential, public places building compartment, commercial decoration rack, clean room board , Hot plate, special cold-keeping project, environmental protection board mold, sports equipment, breeding materials, and other materials, the use of anti-corrosion, , Beach water-proof facilities, water-resistant materials, art materials and a variety of lightweight partitions instead of glass ceiling.

- Q:PVC board and EVA board What is the difference, which is good flexibility

- PVC is a polymer that uses a chlorine atom to replace one of the hydrogen atoms in polyethylene. PVC is the most important feature of flame retardant, it is widely used in fire protection applications. But PVC in the combustion process will release hydrochloric acid and other toxic gases. ? EVA: ethylene-vinyl acetate copolymer is low foaming polyethylene foam plastic. Is a new type of environmentally friendly plastic packaging materials, with good cushioning, seismic, heat insulation, moisture, chemical corrosion, etc., with non-toxic, non-absorbent. Has a good anti-vibration: resilience and high tension, high toughness, With good shock / cushioning performance

- Q:Home decoration kitchen bathroom ceiling selection of PVC or integrated board, which is better point

- Pvc cheap, integrated version of the expensive; integrated board color fashionable and diverse, easy to install, (are package installation) peace of mind, pvc to woodworking master installation, and before installation to play wooden keel; pvc relatively fragile, integrated board mostly solid. The above is the difference between the two. But then come back, if you are not bad economic conditions this money, then the integration board is certainly better, installed up to the grade will be much higher, but the use of speaking, the difference between the two, no one will touch the ceiling every day, so in addition to Beautiful, there is no difference. Yes, the integrated board to buy the integrated module, that is, lamps, fans, Yuba heater, and so have to buy fixed specifications of the integrated board of electrical products, PVC, then choose more, what can be installed. So eventually you just consider your economic affordability, the other is not important, after all, the price difference between the two is very poor. Also to remind you that if you choose integrated board, I hope you can choose brand products, because the integrated plate of water deep, good or bad difference is also great.

- Q:I have a blank PVC gusset plate, plastic material. I want to buy some heat transfer film transfer up, but do not know what equipment through the heat, the general plane thermal transfer machine can it? I am worried that the plastic buckle into the thermal transfer equipment will heat deformation. Please recommend a transfer on the plastic equipment, thank you! Do you buy some blank thermal transfer film through the printer can be printed after the thermal transfer to plastic up?

- Civilian 1610uv printer, printing format 160cm * 100cm, four DX5 nozzle or 5 gs508 nozzle configuration, price 7w-15w. Printing speed of 4-15 square meters / hour. Printing areas are leather, tiles, etc., high-precision, high-speed shop shop equipment. Large 2513 universal printer, printing format 250cm * 130cm, four DX5 nozzle or 4-14 gs508 nozzle configuration or 4-14 gs1024 nozzle configuration, price 16w-60w. Printing speed of 15-80 square meters / hour. Printing areas are glass sliding doors, backdrop, advertising materials, high-precision, high-speed factory batch production equipment.

- Q:What are the shortcomings of PVC products? The more detailed the better.

- Our company is producing pvc glue, I can only provide me to understand. Pvc is a very stable material, mainly used in our sewers and flooring, acid and alkali, wear insulation, durable than iron, is not easy to be corroded, but there are professional solvent dissolved, so link stitching more convenient, these are advantage. Pvc according to different uses to join different additives, showing different physical properties and chemical properties. Because pvc is a general plastic material that is afraid of high temperature, the number of additives added to the pvc material determines the hardness and softness, determines the degree of oxidation. So pvc generally afraid of high temperature, afraid of a specific solvent, afraid of light easily oxidized. These are shortcomings.

- Q:Buy pvc floor need to pay attention to what ah?

- Pvc floor is made of PVC as raw material, this material is non-toxic, no formaldehyde, so there will be no smell, with realistic imitation wood, carpet pattern, stone pattern and other patterns. We can from the sense of smell, touch, vision, hearing simple to determine whether the floor is qualified One: by the sense of smell. In the selection of the floor, with the nose smell, the floor if there is irritating smell distributed, the floor is likely to contain formaldehyde, or formaldehyde content exceeded. Formaldehyde can damage the body's body and have a long release period. Two: by touch. Hand to feel the flexibility of the floor, or feet to feel the floor of the comfort and smoothness. Floor trampling uncomfortable, not smooth, non-slip, are inferior PVC plastic floor. Three: by vision. Floor color is not pure, pattern, pattern is not clear, irregular, the surrounding floor or surface damage and scratches and so can determine the poor quality of the floor. Four: by hearing. Good PVC plastic flooring has a good sound insulation, customers in the selection of the floor when you can try to move around to determine the PVC plastic floor sound insulation effect, sound insulation is poor, are inferior flooring.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Laminated Panel for Wall and Ceiling

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 550000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords