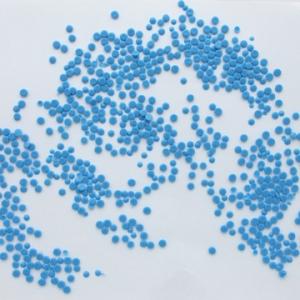

PVC insulating compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

I. Type andapplication

Type | Product | Application and Cable Specification |

7001N | 70℃PVC insulating compound | Used for instrument and communication cables which working voltage less than 0.6/1kV, according with PVC/C standard of GB5023,and J-70 standard of GBT/8815-2008 . |

7002N | 70℃Flexible PVC insulating compound | Used for flexible cables which working voltage less than 450/750V, according with PVC/D standard of GB5023, and JR-70 standard of GBT/8815-2008. |

JGD-70 | 70℃ High electrical properties PVC insulating compound | Used for power cables which working voltage less than 3.6/6kV, according with JGD-70 standard of GBT/8815-2008. |

J-90N | 90℃PVC insulating compound | Used for heat resistant wires and cables which working voltage less than 450/750V, according with PVC/E standard of GB5023, and J-90 standard of GBT/8815-2008. |

PVC insulating compound for wires andcables, based on PVC resin, is made into granula by mixing, plastification andgranulation with adding plasticizer, stabilizing agent, pigment and etc. Theproducts meet various special requirements, such as different hardness, UVstable, environment friend (RoHs, REACH, PAHs, chlorinated alkanes free, phthalate free, and etc.), sub-shine and fogsurface, low temperature resistant, PS/ABS transfer proof, rodent-repellent,termite-repellent, and transparent, and etc.

III.Processing:

Itis recommended that compound should be processed with common extruder having aminimum L/D ratio of 20.

Thefollowing temperature(℃)profile of extruder is recommended:

Zone | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Head | Die |

Temperature ℃ | 140 | 160 | 170 | 175 | 180 | 175 |

Packaging:25kg/bag,PE membrane inside bag and Kraft outside bag.

Storageand transport: Avoiding in direct sunlight and weathering. The storage place shouldbe in clean, cool, dry, and ventilated conditions.

Ⅴ、Properties

Table

Unit | Standard Value | ||||||

7001N | 7002N | JGD-70 | J-90N | ||||

Tensile Strength | ≥ MPa | 15.0 | 15.0 | 16.0 | 16.0 | ||

Elongation at Break | ≥ % | 150 | 180 | 150 | 150 | ||

Impact Brittleness Temperature | ℃ | -15 | -20 | -15 | -15 | ||

≥Ω﹒m | 1.0×1012 | 1.0×1011 | 3.0×1012 | 1.0×1012 | |||

Volume Resistance at working temperature | Temperature | ℃ | 70±1 | 70±1 | 70±1 | 95±1 | |

Volume Resistance | ≥Ω﹒m | 1.0×109 | 1.0×108 | 5.0×109 | 5.0×108 | ||

Dielectric Strength | ≥ MV/m | 20 | 20 | 25 | 20 | ||

Hot Deformation | ≤ % | 40 | 50 | 30 | 30 | ||

Thermal Stability Time at 200℃ | ≥ min | 60 | 60 | 100 | 180 | ||

Thermal Aging |

|

|

|

|

|

| |

Aging Temperature | ℃ | 100±2 | 100±2 | 100±2 | 135±2 | 115±2 | |

Aging Time | h | 168 | 168 | 168 | 240 | 240 | |

Tensile Strength after aging | ≥ MPa | 15.0 | 15.0 | 16.0 | 16.0 | - | |

Variation on Tensile Strength | % | ±20 | ±20 | ±20 | ±20 | - | |

Elongation at Break after aging | ≥ % | 150 | 180 | 150 | 150 | - | |

Variation on Elongation at Break | % | ±20 | ±20 | ±20 | ±20 | - | |

Loss of Mass | ≤ g/m2 | 20 | 20 | 20 | - | 20 | |

Dielectric Loss Factor | ≤ | - | - | 0.1 | - | - | |

- Q:Can olive nets be used for olive trees in regions with high disease incidence?

- No, olive nets cannot effectively be used for olive trees in regions with high disease incidence. The nets may provide some protection against certain pests, but they do not offer sufficient protection against diseases. It is important to implement appropriate disease management strategies and treatments in such regions to safeguard the olive trees.

- Q:Can olive nets be used for olive trees in regions with extreme temperatures?

- Yes, olive nets can be used for olive trees in regions with extreme temperatures. Olive nets serve as protective coverings that shield the trees from excessive heat during extreme temperatures. By providing shade and reducing direct exposure to sunlight, olive nets help to regulate the tree's temperature and prevent damage caused by extreme heat.

- Q:How do olive nets impact the overall cost of olive production?

- Olive nets can significantly impact the overall cost of olive production. These nets are used to cover olive trees during the harvest season to collect falling olives and prevent them from being damaged or lost. By using olive nets, farmers can increase their yield and reduce the amount of olives lost due to factors like wind or birds. This ultimately leads to higher production levels and increased revenues. However, the initial investment in purchasing and installing these nets can be costly, which may affect the overall cost of olive production. Nevertheless, the long-term benefits and improved efficiency provided by olive nets often outweigh the initial expenses, making them a cost-effective solution in the olive industry.

- Q:Can olive nets be used in different soil types?

- Yes, olive nets can be used in different soil types. Olive trees can grow in various soil conditions, such as loamy, sandy, or even rocky soils. The nets are primarily used to collect fallen olives during harvest, which is independent of the soil type.

- Q:Can olive nets be used to reduce water stress?

- Yes, olive nets can be used to reduce water stress. Olive nets help create a microclimate by reducing evaporation and shading the soil, which helps to conserve moisture in the soil. This can be especially beneficial in areas with limited water resources or during dry periods, as it helps to reduce water stress on olive trees and promotes better water retention in the soil.

- Q:How do olive nets affect the development of olive tree branches?

- Olive nets can affect the development of olive tree branches by providing physical support and protection. These nets are used to collect falling olives during harvest, preventing them from being damaged or lost. By catching the olives, the nets reduce the weight and stress on the branches, allowing them to grow and develop more robustly. Additionally, the nets shield the branches from harsh weather conditions, pests, and diseases, promoting healthier growth. Overall, olive nets contribute to the proper development of olive tree branches by ensuring optimal conditions for growth and productivity.

- Q:Can olive nets be used for olive tree sapling protection?

- Yes, olive nets can be used for olive tree sapling protection. Olive nets provide a physical barrier that helps protect the young saplings from pests, birds, and other potential threats.

- Q:Can olive nets be used in traditional olive groves?

- Yes, olive nets can be used in traditional olive groves.

- Q:How do you glue a broken plastic basin?

- Glue the plastic tub in the following way:1, first of all to find a soft plastic bar.2, ignite the plastic bar and drop the melted plastic where it needs to be bonded.3, put out a plastic rod with foil uniformly scrape melted plastic and adhesive.4, wait 5-10 minutes to cool down.

- Q:Where can olive nets be purchased?

- Olive nets can be purchased at gardening supply stores, agricultural equipment retailers, or online marketplaces specialized in horticultural products.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC insulating compound

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 Tons kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords