PVC Iaminated Gypsum Ceiling Tiles / ,PVC Gypsum Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

Normal width:1.48M,1.53M,1.83M,2.0M. 2.35 M, 2.5 M

Translucent Film: Max Width 4.0M

Length: 100 M or 150 M per roll , can be customized

Light Weight:200-300g/M2

Guarantee: 10 years

Fire rating: B1 (Chinese Standard)

Tension: Withstand tension of 185kg per square meter

1 Rich color

Nine series and over hundred colors are available

2 Strong modelling function

the stretch ceiling is a kind of film structure material , deciding ceiling’s whole style according to curving shape of the keel ,,so it styles freely with diversification . Large -scale usage will surely comes to simple smooth interior effect .

3 Convenient installation

The ceiling can be directly installed on wall , square timber, steel structure, gypsum inter-wall and timber inter-wall , suitable for each kind of construction structure , and can be re-disassembled .

4 Fireproofing feature

M-color ranks B1 fireproofing standard , the same with plaster tablet ceiling

5 Energy saving function

Manufactured with PVC material , the ceiling is provided with excellent insulation function , which lowers the loss of interior temperature to save energy .

.

3.Image

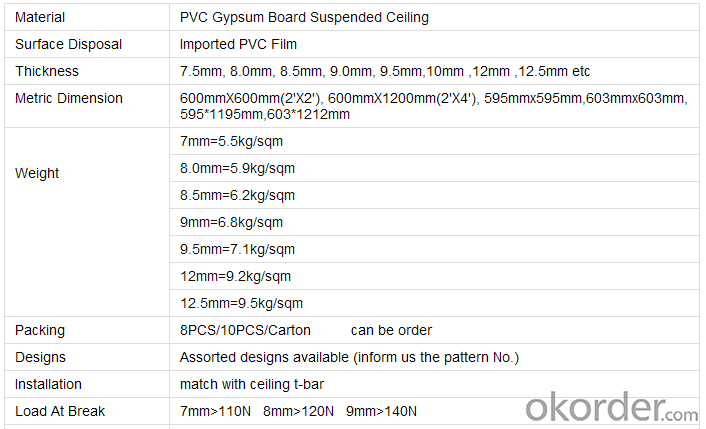

4.Detailed Specification

5.FAQ

Applications

It can be designed with different sizes and styles, widely used for interior ceiling decoration.

Trust us from heart cooperation

Reasonable price

Unique quality

Schedule delivery on time

Updated technology and equipment

Service warmly

1) Commercial & good for decorative

2) Flexible suspension system makes each ceiling tile easily installed and disconnected

3) Easy to match lamps or other ceiling parts

4) Many different pattern

5)PVC film & Aluminum foil back , moisture proof

- Q:I own a restaurant and I currently have plain old drop down ceilings with the plain white tiles. I am looking for a new look in the dining room and would like to install dark brown tin/pvc ceiling tiles. I do not know anything about the, I actually learned of their existence today. I did some research and I can not seem to find any 2 x 4 ceiling tiles for under $15 and considering I need about 150 of them, that can get exremely pricey. In videos and pictures I have seen, they seem like cheap plastic that would not cost much. Please direct me to a website/store where I can get them for around &10 a pop or less.

- Hi, If you can't find them at a better price they actually make a heavy wallpaper that's textured like tin ceilings. The existing tile would need to be primed with Shieldz latex primer, then paste the w/paper to the tiles after the primer has set up (about 1hr ) you can paint them any color & finish you want. We did our bath with 4 embossed tile w/paper & looks great. If i recall the cost is about .75 cents per square foot.

- Q:Is pvc board insulator?

- Seemingly no absolute insulator!

- Q:Pvc board above can stick wallpaper?

- It is best not to paste, is barely able to paste will soon fall off, you can hang gypsum board top paste

- Q:Can I put tiles on the PVC gusset?

- Can not, load is not enough.

- Q:How to quickly tear off the protective film on the PVC board

- Heated with a hair dryer

- Q:Pvc transparent board which are used

- Customers in the choice of a product at the same time the most concerned about the natural function, as the price of this key factor I think it is based on the establishment and function of the above, as long as your product customers with more confidence in the money others will not refuse. Pvc transparent plate surface hardness and high scratch resistance, with excellent anti-static function, impact resistance and chemical resistance of outstanding performance, compact design, of course, this is not the focus, the appearance is limited to human aesthetic point of view, really useful Not that of these. Pvc transparent sheet has a higher hardness and mechanical properties, but also a good electrical properties of the polymer, suitable for pharmaceutical, chemical anti-corrosion materials. Pvc transparent sheet of the screw with a special mixing function and high plasticizing capacity design. This design is easy to adjust the thickness of the plate more accurate, its flatness, lifting methods and the use of screw adjustment methods are very useful, pvc transparent plate independent control of the roller temperature control system can accurately control the pressure roller temperature, so that Thickness of the sheet is uniform. With automatic meter can set the product length, more perfect function

- Q:The head that links into the tub broke off when i was tightening it and i turned the nob so water shouldn't run but its still leaking. My repair guy can't make it for a few days. Its leaking on the rug and going through the ceiling to the first floor!!! I tried to duct taping it but no matter how much i use it still leaks through the cracks after minutes. I need a cheap quick fix till the repairman comes.

- only thing to do is shut off the water either to that area or the whole unit. turn it back on briefly to refill toilets and turn back off before the pipes recharge with full pressure. at least it wont leak as much and especially over night etc. turn on a tap to relieve the pressure in the pipes after you turn off the water.

- Q:Where there are selling pvc board, in addition to walking OKorder

- Jingdong, Sogou, , Alibaba, OKorder

- Q:Pvc board and pp board that is a lot of color, the kind of more suitable for kitchen and toilet waterproof furniture, furniture for the density of the board, specifications and other parameters are generally how much, about how much the price, China Province and the surrounding area Where can I buy this type of plate, the phone number is how much (I need is 1.5cm, 1.6cm and a small part of 1cm and 2cm of the plate)

- PP board: polypropylene (PP) plate, (PP pure plate, modified PP board, enhanced PP board, PP electrode) pure PP board: small density, easy welding and processing, with excellent resistance, heat resistance and Impact resistance, non-toxic, tasteless is the most environmentally friendly one of the engineering plastics. The main colors are white, microcomputer color, other colors can also be customized according to customer requirements. Applications: Acid and alkali equipment, environmental protection equipment, waste water, waste exhaust equipment, scrubbers, clean rooms, semiconductor plants and related industrial equipment, but also the preferred material for the manufacture of plastic water tanks, PP thick plate widely used for stamping Plate, punch and so on. Pvc board: polyvinyl chloride (PVC) plastic is a vinyl chloride monomer by free radical polymerization of the polymer, the English name polyviny chloride, referred to as PVC. PVC board is PVC as raw material made of cross-section for the honeycomb mesh structure of the plate. Is a vacuum plastic film, used for all kinds of panel surface packaging, it is also known as decorative film, with film, used in building materials, packaging, medicine and many other industries. Which accounted for the largest proportion of building materials industry, 60%, followed by the packaging industry, there are several other small-scale application of the industry. According to the degree of soft and hard can be divided into soft PVC and hard PVC. According to the production process can be divided into PVC crust foam board and PVC free foam board.

- Q:Will the production of PVC gray pipe is about 40 meters is normal, after the pipe whitening, from the fish scale, reduce the speed and a little better. What is the reason

- There is a problem with the formula to see if it is too much lubrication

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Iaminated Gypsum Ceiling Tiles / ,PVC Gypsum Board

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords