PVC Honeycomb Reflective Vinyl Roll Honeycomb Solvent Printing Reflective Flex Banner

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specification of PVC Reflective Film

High reflectivity coefficient with micro-prismatic structure, can be illuminated via a single light source

Excellent printability, good ink adsorption, suit for screen printing and digital printing, enable bright and realistic color effect on the printed subject

Waterproof, flame retardant and self-extinguishing property

Energy-saving and environment-friendly

2. Advantages of PVC Reflective Film

Cost effective conspicuity solution

Ideal for retrofitting existing trucks and trailers

Highest nighttime reflectivity in the industry

Prismatic reflector on metallized polyester backing

No edge sealing required

Single layer construction for long life

Thin and flexible for easy application

Withstands high pressure washing and resists edge lift

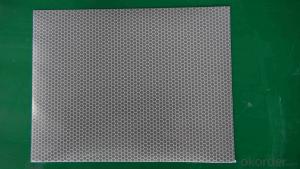

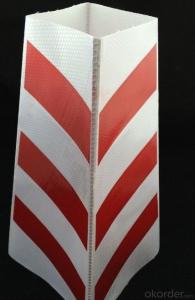

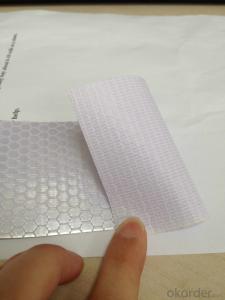

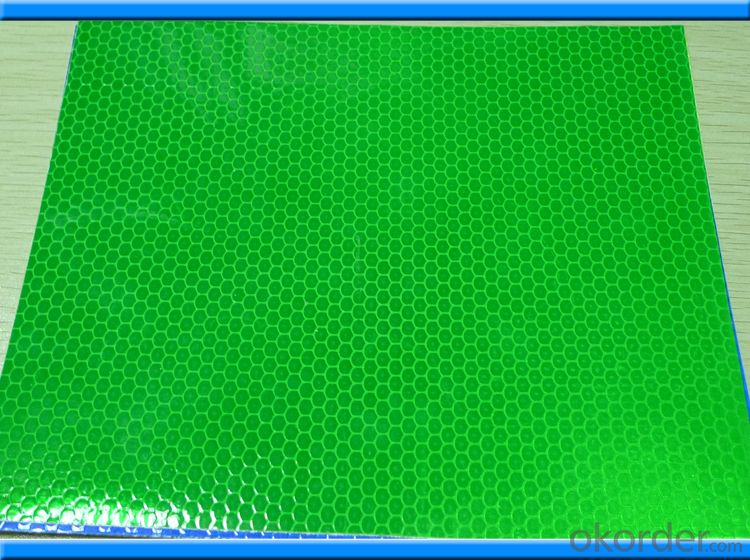

3.Images of PVC Reflective Film

4. Packaging & Shipping of PVC Reflective Film

Packaging Details:

25 rolls in one pallet. Around 600 rolls in one 20ft container.

Shipping Details:

Samples | Lead time:1-2days |

Free samples, Shipping cost should be paid by buyers | |

Bulk lead time | 7-10 days more or less, based on your quantities |

Delivery | Door to door , or FOB Xiamen port china |

Quality Control: We make quality control for each item separately. Shipping department checks each item before packing, totally avoiding manufacturing defects. We care specially about sewing details and fabric quality.

Safe, registered parcel: shipping method, we use, are registered, with tracking numbers. After parcel is sent - we provide tracking number and tracking website.

5. FAQ of PVC Reflective Film

Q: How to get a quotation and start business relationship with your company?

A: Please send us email and our sales representive will contact you as soon as we receive your email.

Q: How to receive a price quotaion in the shortest time?

A: When you send us an enquiry, please kindly make sure all the details, such as the mateiral, product size, surface treatment and packaging are mentioned.

Q: How to start a custom project with your company?

A: Please send us your design drawings or original samples so that we can offer a quotation first. If all details are confirmed, we will arrange the sample making.

Q: What types of payment terms do you accept?

A: Currently, the payment terms we accept are T/T (30% before production, 70% against B/L copy) and irrevocable L/C at sight.

- Q:Why is fiberglass insulation efficient?

- All that a thermometer will do is measure the instantaneous temperature of the fluid inside the glass bulb. Or the instantaneous temperature of the bi-metallic coil. If these objects are exposed to a mode of heat transfer not involving the air, they can give a false reading. That mode is indeed radiation. Air is mostly transparent to radiation, and thus isn't heated by it. Solid objects absorb the radiation, and then the air is heated by convectively interacting with the solid objects. For this reason, thermometers in direct sunlight will read hotter than the surrounding temperature. One method to combat this effect is to use a reflective material and use it for radiation shielding.

- Q:I'm torn between the two. I really love my girl but opportunity is knocking on my door.What would you choose if your in these situation.

- I'd say you're being taken for a ride-0.25 and - 0.5 is barely even anything! My prescription is -3.5 and -3.75 and I do need glasses to drive. If you can pass the eye test at the DMV you don't need glasses to drive.

- Q:More than 75% of the known asteroids:a. crosss the earth's orbit at least once as they revolve around the sun.b.are made of icy material that is highly reflective.c. were once part of the planet as large as jupiter.d. lie farther out from the sun than the orbit of saturne. can be found in a belt between mars and jupiter.

- solar cell tin foal, plastic, + gold filament, ground; [-]silver filament, Lemon juice jello.3.5 volt's add a Coral 1.7 watt's. semiconductor clay aluminum oxide.

- Q:why did American's media (freest media in the world) not show the cartoons of mohammed on TV or newspaper NEWS ?Buddha Jesus get picked on all the time, cartoons abound, but for some reason the media are afraid of Muslims.ARE YOU ?WHY ?

- Fryemall, sorry yet u r an fool. She is calling the thank you to get right of entry to administration Panel. i think of your suggestion every person knows. Now you need to press commence flow to Settings and clickon flow to Taskbar commence Menu. In XO basically appropriate-click on the beginning up button and press concepts or something like that. Than make administration Panel roll-out. Than all you need to do is have been given Administrative kit and computing device administration. From there there are training

- Q:They're beeping about 150 tmes per minute and I don't know why. Not sure if its CO alarm or just something gone crazy. Thoughts?

- This is the health section. That being said, smoking anything is damaging to the lungs.

- Q:How do i bypass my school's filter system, web washer?

- cause' they can't be sold or given away without a ul listing without one.but.hey ! they make good dinner horns !! wolfie told me that a few months ago ! or was that you, making fun of her cooking and smoking up the kitchen ? ha ha !!

- Q:long story short we had to use the fire extinguisher today and we live in an apt building of 6 apts and 3 floors each with 1 extinguisher just wondering does the manager replace/refill or is it our responsibly since we used it. Nothing was damaged but just trying to figure out what to do now

- Reflection photons of light bounce off the surface of the (reflective) material Refraction photons of light and 'deflected' through some angle on entering or leaving (transparent) material of different 'density' Diffraction .. photons under go Quantum interference (with themselves) and the path is PROBABLY bent (or not) in a range of directions ..

- Q:Are fire extinguishers Osha mandated on forklifts?

- Black is the most effective background for most suspended effects coatings. Mirrors are a black background with the reflective material in front of that - look at the back of one, it won't be silver or white, and the coatings are surprisingly thin. Reflective finishes demand very fair surfaces, so it is excellent that you know all about that, and you should be well on the way to a stunning effect finish. You can combine the effect material with the background coats - but only the very top layer will reflect so the effect is reduced. If you apply as the manufacturer instructs, the result will be the best. If you are very knowledgeable and highly experienced you might use alternative application methods and techniques but this is generally not a good idea unless you really know what you are doing. Good luck.

- Q:I'm using poly pipe for my sprinkler system and have used the plastic fittings for the T's and elbows, but is it necessary to use a hose clamp on the ends or is it just an extra precaution?

- its 3m reflective material and its only on certain jordans. my brother collects them haha

- Q:do not want to spoil her fun but you hear such horror stories.

- I live in Florida and I'll quote you what I would charge based on what you're telling me here. I would charge you $50 to change out the kitchen faucet. I'm assuming there is a basement or crawl space under your house since it was built in '45, which makes access to the pipe very easy. I would charge you $150 to change the pipe outINCLUDING material. Pipe just doesn't cost that much. I think that's a reasonable price for you and a fair wage for me. I wouldn't pay to much attention to how long it takes the tradesman to get the job done. Keep in mind, you're paying them more for what they KNOW more than you're paying them for what they DO. I hope that helps.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Honeycomb Reflective Vinyl Roll Honeycomb Solvent Printing Reflective Flex Banner

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords