PVC High Polymer Waterproofing Membrane for Construction Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification of PVC membrane:

|

20m/roll or customized |

Width | 2.05m |

Thickness | 0.8mm, 1.0mm, 1.2mm, 1.5mm, 2.0mm or customized |

Type | Polyester scrim reinforced PVC waterproofing membrane |

If Exposed | Exposed and Non-exposed |

Color | All accepted |

Composition:

The P series waterproofing membrane is a high-quality,thermoplastic PVC membrane with a polyester scrim reinforcement. We solved the problem of extraction and migration of PVC plasticizer in production, make the products the best durability in thermoplastic waterproofing.

Features and Benefits:

l High Strength

l Hot-air welded seams for long-term performance

l Proven membrane performance

l Excellent resistance to plasticizer extraction and migration performance.

Packaging:

The rolls of P series waterproofing membrane are wrapped in a protective film and strapped to a wood pallet. The P series waterproofing membrane lengths of 15m, 20m, 25m, widths of 1.03m, 2.05m and thicknesses of 1.20mm, 1.50mm, 1.80mm, 2.00mm or customized according to customers requirements.

Installation:

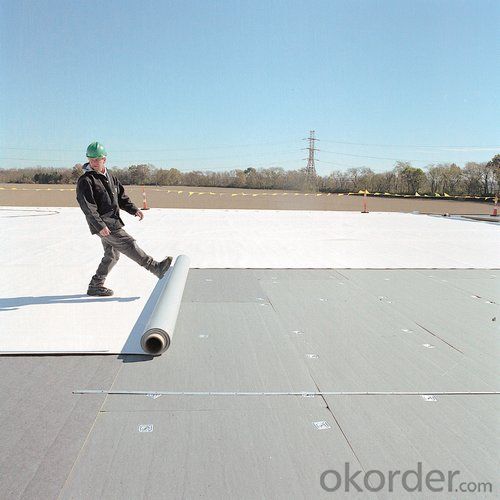

The P series waterproofing membrane is installed by a Magical Stone Authorized Applicator.

P series is rolled out onto the insulation board or acceptable substrate,fastened to the surface and heat-welded together by trained operators using Magical Stone's hot-air welding equipment.

Availability:

The P series waterproofing membrane is available directly from Magical Stone Autherized Applicators. Contact your Magical Stone Regional Office or visit our website for further information.

Warranty:

Upon successful completion of the installed surface by the Magical Stone Authorized Applicator, Magical Stone can provide a Warranty to the Building Owner via the Authorized Applicator.

FAQ of PVC Waterproofing Membrane

a.Can we get some samples before place order?

Answer: We can send the free samples to you by freight collect.

b.How many years can your PVC membrane guarantee?

Answer: We will guarantee the quality for 5 years at least.

c.Which countries you ever export the product?

Answer: We export the PVC membrane to South Africa, Middle east and even European countries.

- Q:Are waterproofing membranes suitable for indoor applications?

- Yes, waterproofing membranes are suitable for indoor applications. Waterproofing membranes are designed to prevent water penetration and moisture buildup, making them an ideal solution for areas that are prone to water damage, such as basements, bathrooms, and kitchens. These membranes create a barrier that prevents water from seeping through floors, walls, or other surfaces, effectively protecting the structure from water-related issues like mold, rot, and structural damage. Additionally, waterproofing membranes can also help regulate humidity levels, leading to a more comfortable and healthier indoor environment.

- Q:Are waterproofing membranes resistant to termites?

- Waterproofing membranes are not inherently resistant to termites. Termites are capable of penetrating various materials, including wood, concrete, and even certain plastics. While waterproofing membranes can provide a barrier against moisture, they do not necessarily protect against termite infestation. To prevent termite damage, it is important to employ additional preventive measures such as regular inspections, treatment of the surrounding soil, and using termite-resistant materials in construction.

- Q:What is the typical installation process for a waterproofing membrane?

- The typical installation process for a waterproofing membrane involves several steps. First, the surface that needs to be waterproofed is thoroughly cleaned and prepared. This may involve removing any existing coatings, debris, or loose materials from the surface. It is important to ensure that the surface is smooth, clean, and free from any contaminants that could affect the adhesion of the membrane. Next, any cracks, holes, or imperfections in the surface are repaired. This may involve filling in cracks with a suitable filler or patching compound, and smoothing out any rough areas. It is crucial to have a solid and even surface to ensure the proper installation and effectiveness of the waterproofing membrane. Once the surface is prepared, a primer is often applied. The primer helps to improve the adhesion between the surface and the membrane. It is typically applied with a brush or roller, following the manufacturer's instructions. After the primer has dried, the waterproofing membrane is installed. There are different types of membranes available, such as sheet membranes or liquid-applied membranes. Sheet membranes are typically rolled out onto the surface and adhered using a suitable adhesive or mortar. Liquid-applied membranes are applied using a brush, roller, or spray equipment, creating a continuous and seamless barrier. During the installation process, it is important to ensure that the membrane is installed correctly, with proper overlap or seams, and that any penetrations or transitions are properly treated and sealed. This includes areas such as corners, edges, drains, and pipe penetrations, where additional detailing may be required to create a watertight seal. Once the membrane is installed, it is important to allow it to cure or dry according to the manufacturer's instructions. This ensures that the membrane reaches its full strength and waterproofing capabilities. Finally, after the membrane has cured, a protective layer or coating may be applied to further enhance the durability and longevity of the waterproofing system. This may involve applying a topcoat, sealant, or protective barrier to protect the membrane from UV rays, foot traffic, or other potential sources of damage. Overall, the typical installation process for a waterproofing membrane involves surface preparation, application of a primer, installation of the membrane, detailing and sealing, curing, and potentially applying a protective layer. It is important to follow the manufacturer's instructions and consult with a professional if necessary to ensure a proper and effective installation.

- Q:Is the asphalt waterproofing membrane facing the side?

- Because there are many types of self-adhesive waterproofing membrane, their use and construction methods are different, there are two main methods. 1, the normal self-adhesive paving method: the film directly paving or polymer cement cement wetting method, paste in the grass-roots level. The bottom of the floor floor of the building, in the concrete cushion with cement mortar leveling, and then the coiled surface of the membrane down, paste in the leveling layer, the roll surface pouring 50 thick stone concrete protective layer, Floor concrete. Wall construction, the film directly attached to the basement wall panels, and then do the protective layer on the outside. Commonly used modified asphalt self-adhesive waterproofing membrane, modified asphalt wet sheet is usually used in this method.

- Q:Are there any specific maintenance requirements for a waterproofing membrane?

- Yes, there are specific maintenance requirements for a waterproofing membrane. Regular inspections should be conducted to check for any signs of damage or deterioration, such as cracks or leaks. Any debris or standing water should be promptly removed to prevent potential damage. Additionally, it is important to follow the manufacturer's guidelines for cleaning and maintenance, which may include periodic cleaning with mild detergents and avoiding the use of harsh chemicals or abrasive cleaning tools.

- Q:Can a waterproofing membrane be installed on vertical surfaces without sagging or slumping?

- Yes, a waterproofing membrane can be installed on vertical surfaces without sagging or slumping. There are specific waterproofing membranes available in the market that are designed to adhere to vertical surfaces and maintain their shape and integrity. These membranes are typically made of materials that have a higher viscosity, allowing them to stick to the vertical surface and resist sagging or slumping. Additionally, some membranes may also have reinforced layers or mesh embedded within them to provide extra support and prevent sagging or slumping. Proper installation techniques, such as ensuring a clean and dry surface, using appropriate adhesives, and following manufacturer guidelines, are also crucial in ensuring that the waterproofing membrane adheres properly and does not sag or slump.

- Q:Can a waterproofing membrane be used for a tunnel waterproofing system?

- Yes, a waterproofing membrane can be used for a tunnel waterproofing system. Waterproofing membranes are commonly used in construction projects to provide a barrier against water infiltration, and they can effectively prevent water from penetrating into tunnels, ensuring their long-term durability and structural integrity.

- Q:Can a waterproofing membrane be used in areas with high humidity?

- Yes, a waterproofing membrane can be used in areas with high humidity. In fact, high humidity can often contribute to the need for waterproofing as it can lead to moisture buildup and potential water damage. Waterproofing membranes are designed to create a barrier that prevents water from seeping through surfaces, such as walls or floors. They can effectively protect against moisture and water infiltration, which is particularly important in high humidity areas where the risk of water damage is greater. By applying a waterproofing membrane, you can significantly reduce the likelihood of mold, mildew, and other moisture-related issues in these environments.

- Q:Can a waterproofing membrane be used for roof gardens?

- Indeed, the utilization of a waterproofing membrane is applicable for roof gardens. In truth, it is strongly advised to implement a waterproofing membrane on the roof prior to establishing a garden in order to avert water leakage and harm to the underlying structure. Acting as a shield between the garden and the roof, the waterproofing membrane guarantees that water does not permeate through, thus preventing issues like leaks, mold, or structural destruction. It aids in safeguarding the roof against moisture, root intrusion, and other elements of the environment. Consequently, the inclusion of a waterproofing membrane is imperative for the prosperous and enduring installation of a roof garden.

- Q:Can a waterproofing membrane be used for tunnels and underground structures?

- Yes, a waterproofing membrane can be used for tunnels and underground structures. Waterproofing membranes are commonly used in construction to provide a barrier against water infiltration and protect structures from potential damage caused by water. In the case of tunnels and underground structures, where there is a higher risk of water ingress due to the surrounding soil and groundwater, waterproofing membranes are essential to ensure the integrity and longevity of the infrastructure. Waterproofing membranes for tunnels and underground structures are specifically designed to withstand the unique challenges posed by these environments. They are typically made of durable and flexible materials such as bitumen, PVC, or EPDM, which can effectively resist water pressure and provide long-lasting protection. Additionally, these membranes are often reinforced with various layers or fabrics to enhance their strength and resistance to puncture or tear. The application of waterproofing membranes in tunnels and underground structures involves a meticulous process. The surfaces that need to be waterproofed, such as the walls and floors, are thoroughly cleaned and prepared to ensure proper adhesion of the membrane. The membrane is then applied in multiple layers, ensuring complete coverage and a seamless seal. Special attention is given to critical areas such as joints, corners, and penetrations to prevent any potential weak points. By using a waterproofing membrane, tunnels and underground structures can be effectively protected from water intrusion, groundwater pressure, and potential damage caused by moisture. This helps to maintain the structural integrity of the infrastructure, prevent water-related problems such as leaks, corrosion, or deterioration, and ensure the safety and functionality of the tunnel or underground facility.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC High Polymer Waterproofing Membrane for Construction Field

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords