PVC Gypsum Ceiling Low Price Tiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

1,gypsum ceiling factory manufacture

2,good quality and low price.

3,easy install and looks beautiful.

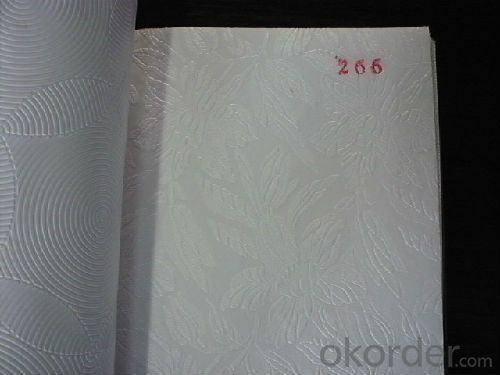

PVC gypsum board ceiling tiles:

Product Advantages:

size::593*593mm,595*595mm,598*598mm,600*600mm, 603*603mm,

thickness: 7.0mm,7.5mm,8.0mm,9.0mm,12mm

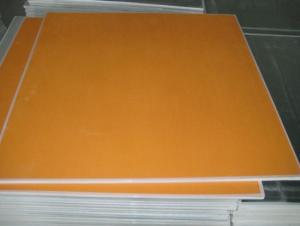

color:white,red,pink,green,blue,yellow,golden ect.

certificate: SGS, ISO9001

Main Product Features:

Item | Gypsum board ceiling tiles

|

Size | 595x595mm,600x600mm,603x603mm,595x1195mm,603x1212mm etc

|

Thickness | 7mm,7.5mm,8mm,8.5mm,9mm,9.5mm,10mm,12mm

|

Weight | 7mm<6.5kg/m2,8mm<7.5kg/m2,9mm<8.5kg/m2

|

Packing | Shrink packing,8pcs/ctn or 10pcs/ctn.

|

Strength | >160N

|

Installation | Suspending the pvc gypsum board with the T-grids,it is very easy.

|

Advantage |

Waterproof,moisture-proof,heat protection,prevent sinking, economical,elegant,fashionable,green ceiling decorative materias

|

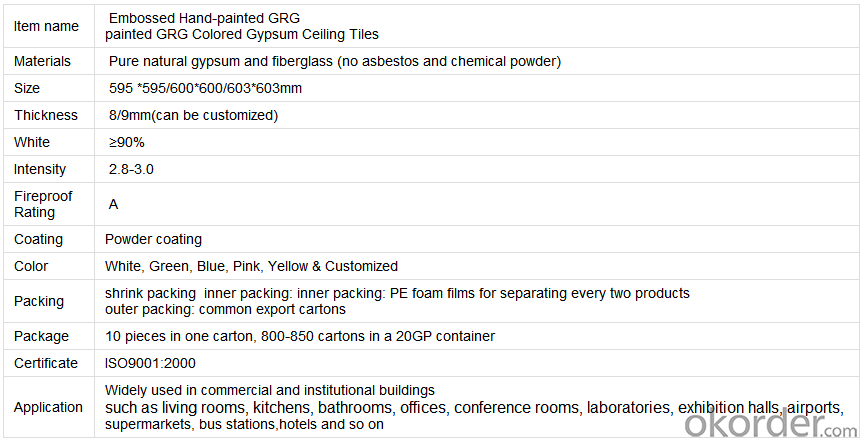

Product Specifications:

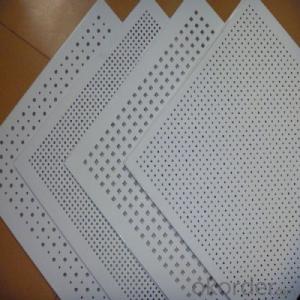

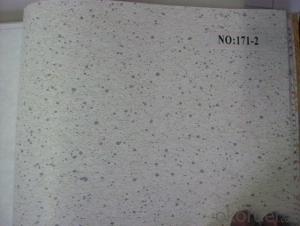

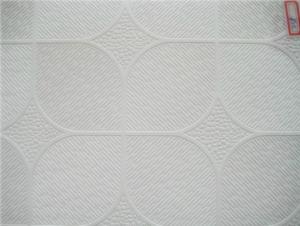

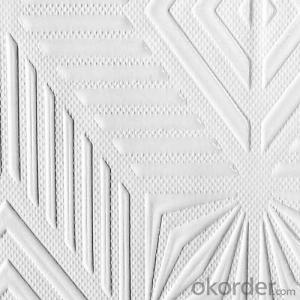

Images:

- Q:How to use half water gypsum to make ceiling cracks

- Gypsum board ceiling cracking repair will crack. In the installation of gypsum board, if there is no installation specifications from the middle to the four sides of the screw, but from the four sides at the same time on the screw, then the gypsum board will produce stress, if the stress is large enough, will cause cracking; Gypsum board screw spacing is too large or some screw position, although correct, but if not fastened, will lead to cracking.

- Q:Can the bathroom be covered with gypsum

- Can not be gypsum ceiling fear tide toilet water vapor too long a long gypsum board will be tide cracking deformation proposed landlord to PVC or integrated ceiling look a lot of now

- Q:Home furnishings in the general use of what material to the ceiling look good?

- It has the following advantages: 1, gypsum board has a good decorative effect and good sound absorption performance. 2, moisture, no deformation, fire, fire, and the construction of convenient, good processing performance, can be sawing, planing, can be bonded, etc., 3, the main varieties are: all kinds of flat, pattern relief plate, semi-perforated plate, all perforated plate, waterproof board. Pattern relief board for living room living room, bedroom, study ceiling. If it is a bathroom and kitchen ceiling, it is recommended that you use the integrated ceiling.

- Q:is gypsum board or plaster ceiling contents gypsum safe ? i mean for long term effects to health?

- Short term exposure is no problem with most minerals in the building trade, long term exposure can cause scar tissue/fibrosis build up in the lungs and a remote chance of cancer. Get some dust masks they don't stop it all but they are better than nothing.

- Q:Light steel keel gypsum board ceiling belongs to the Ming keel or dark keel

- The distinction between the ceiling and the dark keel is generally found in the T-shaped keel mineral wool board or gypsum board ceiling. The panel used in the Ming keel is placed directly on the keel so that the keel is exposed; the keel is used with a slot , Is inserted into the keel, so the keel is covered by the plate and can not see.

- Q:The type of ceiling ~ ~ ~ ~ detailed point ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~ ~

- Plywood Plywood (also known as plywood) with a light material, high strength, good flexibility and toughness, impact resistance and vibration, easy processing and finishing, insulation and so on. It can also easily create a variety of curved, round, square and other shapes of smallpox, but the disadvantage is afraid of termites.

- Q:Bedroom 23 square meters to do ceiling, gypsum board ceiling about how much cost? Integrated ceiling

- Bedroom with gypsum board ceiling it, integrated ceiling for kitchen and toilet.

- Q:Decoration with gypsum board ceiling joints need to gap, generally stay much

- Ceiling decoration with gypsum board, considering the temperature difference between the joints need to have gaps, usually 2 ~ 3mm.

- Q:House ceiling gypsum line, if one of the two gypsum lines (east and south) fall, then the remaining two directions of gypsum line will not fall off? Is it safe? If you use a transparent tape attached to the remaining gypsum line, can you? No ceiling. Relatively thin plaster line. Not their own house, so would like to simply deal with

- Will not fall in the original gypsum paste is not strong solid, transparent tape is sticky it, AB glue is also almost

- Q:Gypsum board ceiling, how to fill the bandage it?

- With caulking material filling, and then use high-strength seam tape with sewing reinforcement. The following is my finishing information, you can refer to: (1) before the construction of the first slit surface treatment, remove the dust, loose objects and a variety of materials is not conducive to bonding. And then use a mud knife to reconcile the good gypsum caulking cream on the edge of the wedge edge. Determine the location of the seam tape, and then use the mud knife will be stitched in the upper end of paper. (2) and then use the mud from the top down out of the excess gypsum caulking cream, so that the paper firmly with the gypsum board, the paper center line and slit alignment. With a mud knife to gypsum caulking paste thinly applied to the surface of the joint paper tape, the seam paper tape completely painted. Scrape off the excess seam paste with a knife. After solidification, if necessary, it can be polished with fine sandpaper. (3) with a mud knife cast a thin layer of the second layer of gypsum caulking paste, both sides were widened the first layer of about 50 mm, dry and then fine sandpaper polished smooth. (4) evenly cast on both sides of the corners of the gypsum caulking paste. Fold the seam paper tape after the paste into the corners, so that it is tightly embedded in gypsum caulking paste. The same plane seam also used the mud knife from the top down out of the excess caulking cream

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Gypsum Ceiling Low Price Tiles

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 4000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords