PVC Foam Sheet with Best Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

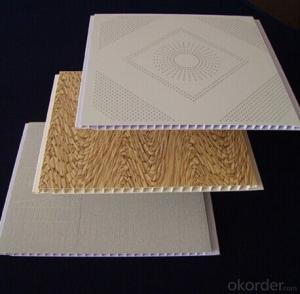

PVC Foam Sheet, a kind of high-tech product, is one product of Kingstar Plastic Sheet series. Through special machinery and technology processing, the main material PVC resin can be foamed and extruded into a special sheet with many advantages, such as shinny or matt surface, waterproof, flame-resistant, UV stable, sound and heat insulation, anti-chemical corrosion, etc.

Kingstar PVC Foam sheet is manufactured by the equipment imported from well-known Italian Bausano Group and Austria Cincinnati Company. We, with more than 15 years' processing experience, have invented several formulas to ensure every piece of sheet could be perfectly used.

Application

Advertising Signs, billboards, displays, exhibition stands

Screen printing, laser engraving

Thermoformed parts

Architecture, indoor and outdoor decoration

Furniture, kitchen & bathroom cabinet

Walls & partitions, wall cladding

Poolside furniture, swimming pool floor planking

Board for Chemical industry and laboratory equipment

Interior scaleboard for boat & ship, vehicle, train

Features

Light weight, easy and convenient to storage, transportation and use

It could be drilled, sawed, nailed, turned, glued, bended, printed, oiled, etc

Uniform fine & close cell structure

Hygienic, Rigidity, Durable

Perfect chemical corrosion resistance, good resistance to UV & weathering

Fire retardant and self extinguishing

Moisture-resistant, mildew proof, rot proof, low water absorption

Non-deformation, color fastness for a very long time

Sound insulation, sound absorption, heat insulation and heat preservation

Easily to put protective film on one or two sides

Smooth surface and suitable for silk-screen printing, laser engraving (must clean the surface before printing)

- Q:Finished pvc board how to install the kitchen led lights

- In the position of two keels to open less than the lamp can be tightly embedded in the hole, the wiring installation fixed

- Q:Whether the pvc board is poisonous

- How to say this, pvc plate is mainly plastic material, case of heat easily deformed at the same time the distribution of gas, toxicity is certainly some home decoration do not use PVC, kitchen and toilet area is not great, with more than 100 points button Hanging good, PVC will be yellow for a long time. Individuals are not in favor of ceiling with PVC board.

- Q:Like pvc board and so on how to cut, very bad bonding it?

- Generally with ABS board, pvc board, acrylic, plexiglass, it is recommended to buy engraving sculpture, the first glue is better, you can buy imported plastic.

- Q:PVC flooring can not be used at home, there is no pollution

- can. Because the durability of pure wood flooring is not very good. And if the living room with pure wood. Out of the guests more, then the damage is great. And pure wood water resistance is not very high A long time in the process of mopping the sky easy to tilt. PVC is also a composite wood flooring. The use of the living room more. The cost is also low. Pollution to not really. Selection of regular manufacturers. When the delivery can be heard there is no pungent odor. No can be. After the new house is renovated. Cut a few raw pineapples in the room. Can effectively remove the decoration air pollution.

- Q:I use the PVC wall to do the backdrop, there are three square, one centimeter thick PVC board how to fix to the wall, is the use of glue or nails or other methods, with glue what is the glue. It is best to get their own home to the point of advice Thank you

- Fixed a lot of ways to use plastic bolts with plastic bolts ??? The most easy way to fight a few holes on the wall of a few holes with plastic plastic nail fixed nail surface decorated with a very beautiful hat

- Q:What is the difference between acrylic and PVC?

- Acrylic transparency is relatively high, but not impatient, not resistant to solvents and so on ? Acrylic, also known as PMMA, plexiglass and other engineering plastics PVC is PVC, is a general plastic.

- Q:I am going to be sealing the wall when making the basement a family room. Between the sump pump shooting out and the water traveling through the pipe, it's noisy. Anything that will quiet this?

- You will never get rid of all the sound, but you might dampen it a bit by insulating around the pipes. You can use fiberglass insulation (batts) and stuff it around the pipe before you close them up. If you insulate the entire ceiling it will also keep the family room noise from disturbing people upstairs from noisy people down stairs. (I almost said from teenagers, but that might not be politically correct LOL).

- Q:What is the pvc board? Durable?

- PVC is a PVC, a plastic, waterproof good

- Q:Bathroom with pvc ceiling is good or aluminum plate good? why?

- Bathroom ceiling or choose an integrated ceiling class, With aluminum-plastic plate material ceiling, its practice and effect of course have their own advantages, Although we are aluminum composite panel manufacturers, but frankly speaking, the use of aluminum-plastic board is mainly moisture moisture problem. Not the aluminum-plastic plate material itself, but supporting the accessories and accessories, such as wood plywood, seam density and so on.

- Q:Pvc floor how much money

- According to the requirements are not the same, the level of different grades, so the price is also different. But the basic price of 25 yuan / square to 150 yuan / square are. The higher the requirements, the higher the grade, the more expensive the price

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Foam Sheet with Best Price

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords