PVC Foam Board/Sheet/Panel Plastic Cutting Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Product Introduction

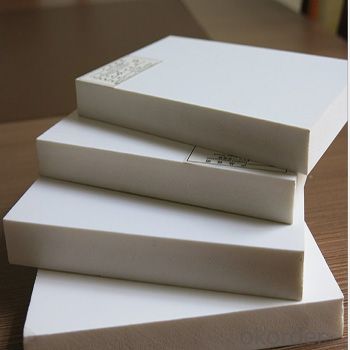

PVC foam sheet is made from polyvinyl chloride, with flat plate surface; it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anticorrosive, metabolic and recyclable, moisture resistant, lightweight.

The PVC foam board is made through foaming and pressing into shape with additive. It is widely used in Sanitaryware, Construction material and Advertising material.

PVC celuka foam board, white pvcfoam board,black pvc foam board,colored pvc foam board,red pvc foam board,yellow pvc foam board,green pvc foam board,blue pvc foam board and so on.

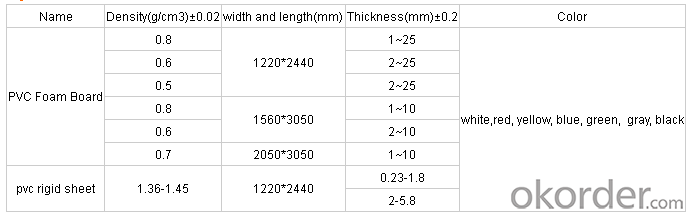

2.Product Specification

Regular size: 1220*2440mm, 1560*3050mm, 2050*3050mm,as your request.

Thickness:1-33mm

Density:0.35-0.9

3.Product Features

(1) Light weight, waterproof,

(2)Fire retardant and self-extinguishing

(3) Sound insulation,

(4) Heat insulation,

(5)Noise absorption,

(6)Heat preservation and anti-corrosion.

(7) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(8 Easy to clean and maintain.

(9) Environmental- friendly green and lead-free.

4.Product Application

(1)Advertising: exhibition display, digital printing, silk screen printing, computer lettering, sign board, light box, etc.

(2)Construction: office and bathroom cabinets, inner and outer decorate panel, commercial decorating shelf, room separating

(3)Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layer and other industry.

(4)Galleries, exhibition, saloons, stores, offices, banks, hotels, restaurants and apartments

5.FAQ

How to get the price?

Please tell me the following information and I'll send you the quotation without delay:

1. size (1220 x 2440 mm or the size you need)

2. thickness (1-33mm)

3. density (0.43mm-0.9mm)

4. quantity

6.Pictures of PVC Foam Sheet

7.FAQ

Q1. What's your shipping way?

• By Sea ( it's cheap and good for big order)

• By Air ( it's very fast and good for small order)

• By Express, free choice Fedex, DHL, UPS,TNT, EMS, ect... ( door to door service)

Q2 What is the sample time and mass production time?

• Sample time is 1-3 days.

• Mass production time will depand on the quantity, small order production time is

5-7 days, big order production time is 15-20 days.

- Q:water has an angle of incidence of 35.0 degrees. At what angle does the light enter the air?

- Actually the plastic sheet does not enter into the problem.. Let n_w = n water = 1.33; n_p = n plastic = 1.500; n_a = n air = 1.00 Now using Snell's Law we have n_w*sin(thetaw) = n_p*sin(thetap) = n_a*sin(thetaa) See how the middle part of the eqn is not needed... So n_w*sin(thetaw) = n_a*sin(thetaa) Therefore thetaa = arcsin(n_w/n_a*sin(thetaw)) arcsin(1.33/1.0*sin(35)) = 49.7o

- Q:Are plastic sheets suitable for laser cutting?

- Yes, plastic sheets are suitable for laser cutting.

- Q:What are the thermal conductivity properties of plastic sheets?

- The thermal conductivity properties of plastic sheets vary depending on the type of plastic used. Generally, plastic sheets have low thermal conductivity, meaning they are poor conductors of heat. However, certain types of plastics, such as high-density polyethylene, can have relatively higher thermal conductivity compared to others.

- Q:What are the common kinds of plastic sheets?

- More assured. Benefit home board is E0 class, lower than the national standard, custom wardrobe, cabinets, wine cabinets and so on

- Q:What are the different thickness options available for plastic sheets?

- The different thickness options available for plastic sheets can vary depending on the type of plastic, but commonly range from 0.5mm to 12mm or even thicker for certain applications.

- Q:Can plastic sheets be used for DIY room dividers?

- Yes, plastic sheets can be used for DIY room dividers. They are lightweight, affordable, and easy to work with. However, keep in mind that they may not provide as much privacy or sound insulation as other materials like wood or fabric.

- Q:Can plastic sheets be used for vacuum forming?

- Yes, plastic sheets can be used for vacuum forming.

- Q:I have tried a variety of tapes that all slowly fall off over time. I'm looking for a more permanent way to attach two flat sheets of plastic about 10x10 together to form a seam.

- depending okorder

- Q:Hi guys! I once saw a plastic sheet with milky color. When coveredagainst a dark background plate, one can write on it with an ink-lesspen. But when the pastic is taken off the background plate, the handwritingdisappears. Do you know what it is and where I can buy it?

- the front sheet is an opaque pvc over a dark blue card with blue wax over it. when you write on the pvc it presses the pvc onto the wax and the text appears, pulling the pvc away from the wax removes the image and resets the tablet.

- Q:is there a small machine for welding plastic sheeting together? I wish to make pencil cases and such.?

- i would just use a hot glue gun.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Foam Board/Sheet/Panel Plastic Cutting Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 10000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords