PVC Foam Board/Sheet Construction Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction

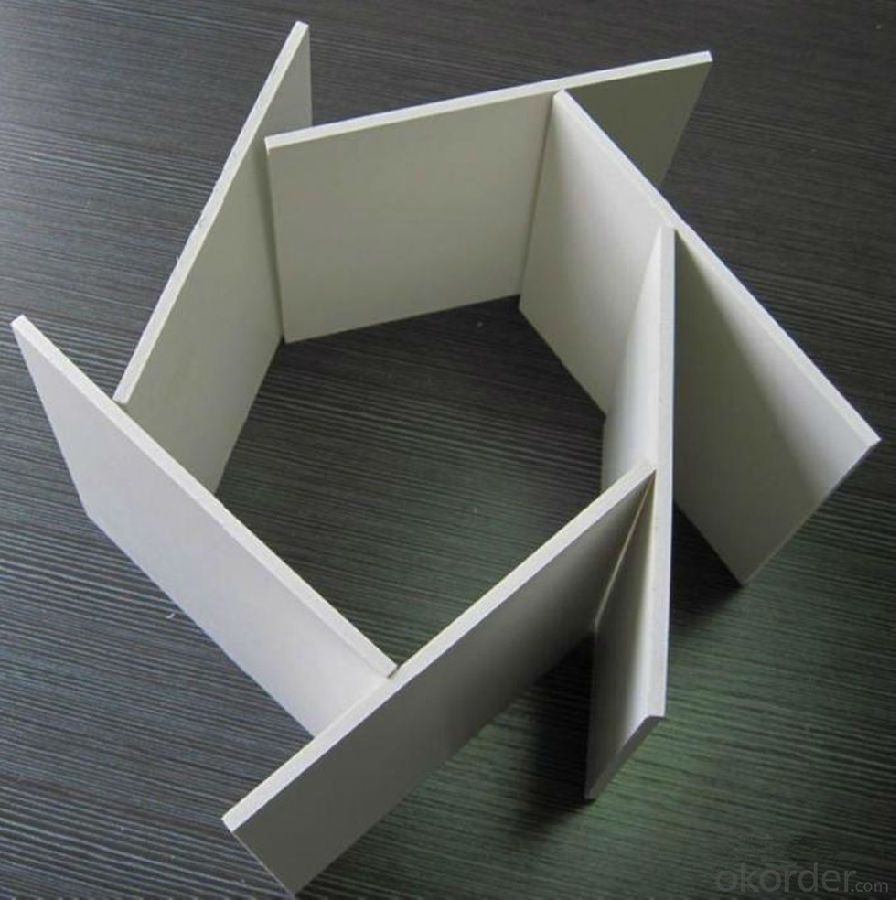

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

The PVC free foam sheet extrusion line consists of special designed twin-screw extruder, T-die, shaping mould and related downstream line. It has the characters of high output, stable extrusion, low cost for maintenance and high foamed ratio for the finished product. By cooperating with printing, laminating and hot stamping machine, all kinds of imitation wood products can be easily produced in this line.

2. Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm

Thickness:1-33mm

Density:0.35-0.9

3. Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

4. Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

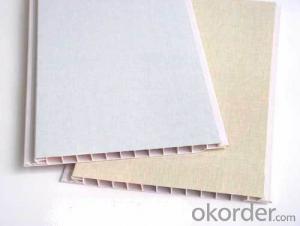

5.Pictures of PVC Foam Board

6.Factory Pictures

- Q:Can plastic sheets be used for electrical insulation in high voltage applications?

- Yes, plastic sheets can be used for electrical insulation in high voltage applications. Plastic materials such as polyethylene, polypropylene, and PVC have excellent insulating properties and are commonly used for insulation in high voltage systems. These materials have high dielectric strength and can withstand the stresses and voltages associated with high voltage applications, providing a reliable and cost-effective insulation solution.

- Q:I want to renovate my basement, but as I was walking through my local hardware store, I noticed a variety of sheetrock that are mold resistant to fire resistent and at different thicknesses. Is a thicker board better for the basement?Also, is there a way to test moisture in a basement over sheetrock or would I have to remove the sheetrock and apply a plastic sheet with tape to test for moisture?thanks!

- You should really use mold retardant sheetrock in the basement. It might actually be required by code depending on where you live. I helped a guy fix up a house and the inspector told him to sheetrock the ceiling of the basement and use 1/2 mold resistant sheetrock. The differences you get with thickness of sheetrock is mostly durability. Obviously thicker sheetrock will hold up longer. On ceilings especially, the 3/8 inch sheetrock will bend over time between the rafters (or floor joists in the basement) where it is screwed in. There is also a difference in sound-proofing, you hear less through walls of 5/8 than 3/8. The last difference is fire resistance, 5/8 inch sheetrock takes significantly longer for fire to burn through than 3/8. To chose which one you want to use, find out what the code requires in your area. You may be required to use mold resistant sheetrock, or you may be required to use fire resistant boards. I would use 1/2 in the basement because it is a lot easier to hang than 5/8 and you have decent durability and unlike 3/8, it will not bend or bow over time. I actually saw mold resistant fiber tape for the joints in The Home Depot, you might want to use that whether or not it's required by code just for extra measure. Some things may be more expensive to do to the tee, but if you cheap out now, you may end up pending more fixing things if they go wrong or get messed up later down the road. And most importantly, do every single thing to code and pull permits for everything, that way you are covered on all your bases.

- Q:It's a very funny song and my mother would like the sheet music. So if anyone has it or knows where I could get it for free that would be most helpful.

- It was a standard of the Chad Mitchell Trio and I know the song well, but I haven't a clue where you could get the music unless you watch the movie Cool Hand Luke with Paul Newman... he sang that song in the scene after his mother died, so you could get someone to write it down for you. Oh I don't care if it rains or freezes... long as I've go my plastic Jesus... right here on the dashboard of my car.... He is plastic, pink and pleasant... always smiling... ever present... whether I am driving near or far.

- Q:i use type 6 plastic[the plastic containers that salads normally come in] as shrink plastic to make shrinkydinks.but i was wondering is there another place to purchase it other than shrinkydinks?easy 10 points.

- I don't know about type 6 plastic. but you can buy 6 mil. plastic at most any hardware store, wal-mart or home improvment store.

- Q:What is the difference between PVC plastic gusset plate and aluminium alloy gusset plate?

- Aluminum buckle: Aluminum gusset lies not in thickness, but in materials, household boards can be 0.6MM, because unlike steel plate aluminum plate that span of existence problem, select the key on the board of the elasticity and toughness, followed by surface treatment. Because of its color, decoration and weather resistance, aluminum gusset plate is widely used in outdoor curtain wall decoration and indoor high-grade home decoration, advertising decoration and so on,

- Q:What is the maximum temperature plastic sheets can withstand?

- The maximum temperature that plastic sheets can withstand varies depending on the type of plastic. Some plastics can withstand temperatures up to 300 degrees Fahrenheit (149 degrees Celsius), while others may have a maximum temperature resistance of 500 degrees Fahrenheit (260 degrees Celsius) or higher. It is crucial to refer to the specifications provided by the manufacturer to determine the specific maximum temperature resistance of a particular plastic sheet.

- Q:Can plastic sheets be used for chemical storage containers?

- Yes, plastic sheets can be used for chemical storage containers. However, it is important to choose the right type of plastic that is chemically resistant to the specific chemicals being stored, as some chemicals can react with certain types of plastic and compromise the integrity of the container. Additionally, proper safety precautions and labeling should be followed to ensure the safe storage and handling of chemicals.

- Q:What is an extrusion plate?

- With high thermal resistance and low linear expansion ratio, the characteristics of the low, the obturator structure rate reached more than 99%, the formation of a vacuum layer, avoid air flow cooling, to ensure that the insulation performance of lasting and stable, relative to the closed cell foam polyurethane rate of 80%, the leading advantage is self-evident. Practice has proved that the insulation effect of 20mm thick XPS extruded insulation board is equivalent to that of 50mm thick foamed polystyrene and 120mm thick cement perlite. Therefore, this material is currently the best choice for building insulation.

- Q:I need a piece of flat sturdy plastic about 1/8 thick. Does anybody know where I can buy this? I dont want plexiglass, its too expensive.

- You okorder / okorder / GOOD LUCK !!

- Q:Company wants me to pay extra for it but why do I need it?

- Probably to keep the moisture in the soil and not make the air under there damp. Wise investment if done properly. I sure hope he intends to put the plastic on the ground, right?

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Foam Board/Sheet Construction Foam Board

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 pc

- Supply Capability:

- 10000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords