PVC Foam Board and Sheet Raw Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 1000 mm/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Product Introduction

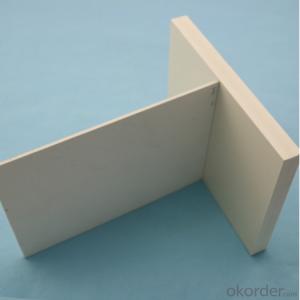

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof,anticorrosive,ametabolic and recyclable,moisture resistant,lightweight.

2. Product Specification

Regular size: 1220*2440mm,1560*3050mm,2050*3050mm or as your request

Thickness:1-33mm

Density:0.35-0.9

Production Capacity:10000pcs per month

3. Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

4. Product Application

(1) Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

(2) Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

(3) Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

5.Product Pictures

- Q:Do plastic sheets have any impact on plant growth or agriculture?

- Yes, plastic sheets can have a significant impact on plant growth and agriculture. Plastic sheets, such as mulch films, are commonly used in agriculture to enhance crop production. They can help regulate soil temperature, conserve moisture, control weed growth, and protect plants from pests and diseases. Additionally, plastic sheets can also extend the growing season by creating a greenhouse-like environment, allowing for the cultivation of crops in regions with unfavorable climates. Overall, the use of plastic sheets in agriculture can greatly benefit plant growth and improve agricultural practices.

- Q:Can plastic sheets be used for protective covers?

- Yes, plastic sheets can be used as protective covers due to their durability, flexibility, and ability to shield objects from dust, moisture, and other potential damages.

- Q:We are in the process of building a roof over our concrete 10x10 patio. We have put 2 4x4's on the front two corners and the other edge without 4x4s is attached to the side of the house. We are using 2x6's along the length of it as support along the top and then will top with 1x4's before putting on the roof sheets of our choosing. Our neighbor that has helped us used white plastic looking sheets on his roof of the same design (I believe the brand is tuftex?). When we went into the store the other day I noticed Green Metal Sheets (Tin I believe)... the price difference isn't really an issue but I want it to be decent quality at the same time... any suggestions or comments on the pros and cons of each? Any other ideas?Thanks

- Scotto is right about not using metal in a salt environment, and the noise factor. The last consideration is that metal will absorb more heat from the sun and Polycarbonate or vinyl will keep your patio a bit cooler. Also if you opt for the opaque type you will have more light.

- Q:They need to be non-adhesive.

- there are a wide variety of UV protective plastic sheeting in many hardware stores and online you do know however, just protecting the labels from UV light won't protect them from the actual light, which can still cause the labels to fade.

- Q:What are the temperature limits for plastic sheets?

- The temperature limits for plastic sheets vary depending on the type of plastic. However, most plastic sheets have a temperature range of around -40°C to 80°C (-40°F to 176°F).

- Q:Are plastic sheets resistant to moisture?

- Yes, plastic sheets are generally resistant to moisture due to their non-porous nature, which prevents water absorption.

- Q:Can I use all these plastics sheets and duct tape I bought after 9/11 to protec me from e. bola?

- Hide in your Y2K bunker till this all blows over

- Q:What is the difference between PVC plastic gusset plate and aluminium alloy gusset plate?

- PVC plastic buckle with PVC as raw material, light weight, easy installation, waterproof, anti moth, surface color pattern change very much, and resistant to pollution, easy cleaning, good sound insulation, heat insulation performance, flame retardant materials especially adding new technology, so that it can from the fire that destroyed, use more safety. Is to Aluminum Alloy aluminum gusset plate as the substrate, by cutting, shear angle, compression molding, surface coating of aluminum buckle various processing of aluminum buckle products, aluminum buckle, mainly divided into two types, one is the home integrated aluminum buckle, the other one is engineering aluminum buckle, the primary Jiezhuang aluminous gusset plate to rolling and matte series of two main.

- Q:Are plastic sheets resistant to UV degradation?

- Yes, plastic sheets can be resistant to UV degradation depending on the type of plastic used and any additional UV stabilizers or coatings applied.

- Q:What are the disadvantages of using plastic sheets?

- One major disadvantage of using plastic sheets is their negative impact on the environment. Plastic is non-biodegradable and takes hundreds of years to decompose, contributing to pollution and litter. Additionally, the production of plastic sheets involves the extraction and processing of fossil fuels, contributing to climate change and depletion of natural resources. Plastic sheets are also prone to tearing and damage, making them less durable compared to other materials.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Foam Board and Sheet Raw Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 mm

- Supply Capability:

- 1000 mm/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords