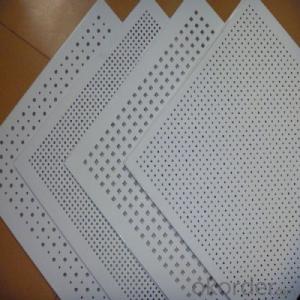

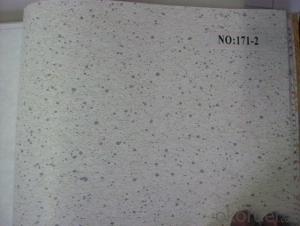

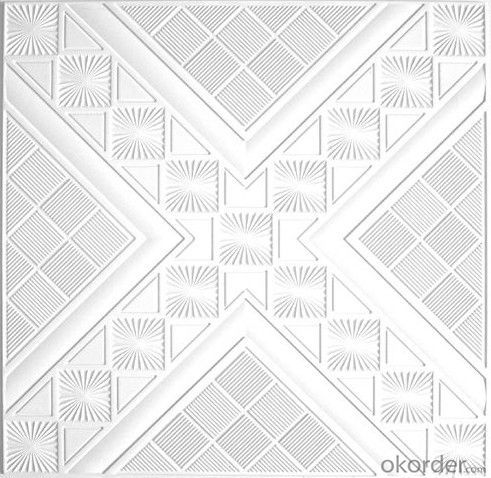

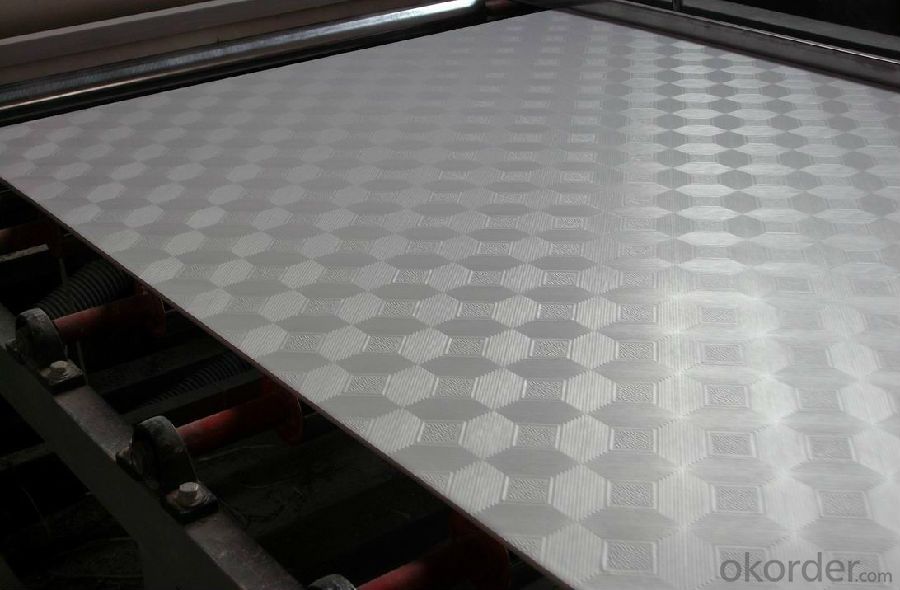

PVC Faced Gypsum Board Ceiling Tiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 540000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Laminated Gypsum Ceiling Tiles

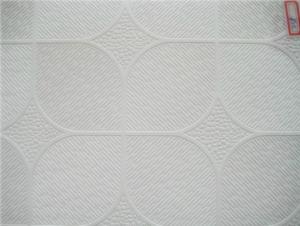

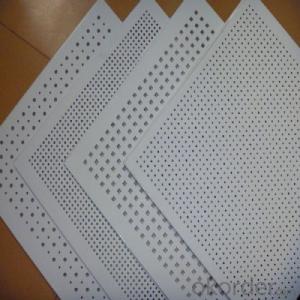

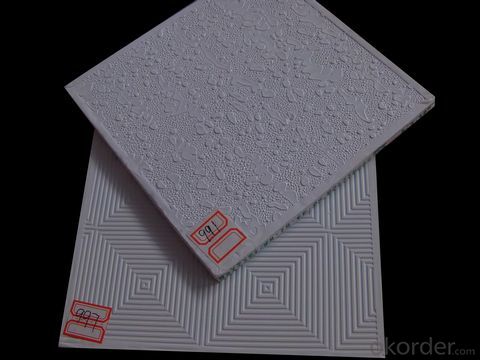

pvc gypsum ceiling tiles /gypsum ceiling board The modern decorative ceiling is wildely used for some large buildings such as business buildings, The False Ceiling tiles enjoy some special advantagement :moisture-proof, fire proof, dirty-proof,

| |||||

Normal Size | Thickness | SQM/20' | Gross Weight | Composement | Package |

595*595mm | 7 | 4000 | 23600 | pvc new design

plaster gypsum board | Carton

10pcs/ctn |

| 7.5 | 3800 | 23800 | |||

| 8 | 3600 | 23000 | |||

| 8.5 | 3400 | 22800 | |||

9 | 3200 | 22600 | |||

| 9.5 | 3000 | 22200 | |||

| 10 | 2700 | 21800 | |||

12 | 2200 | 20800.00 | |||

We also the professional manufacturer of ceiling tee bars for gypsum boards matching.So pls don't | |||||

Packing: Carton, 8PCS/carton or according to customers' demand

Shipment: Within 20days after receipt of the deposit of T/T, L/C;

Minimum Order: 1x20ft container

There are 51 different colorful pvc patterns and 31 vinyl pvc for you to select.

A.Specifications:MM

| Length x Width

| 595x595,595x1195,600x600,603x603, 605x605,603x1212,610x1220(2'x4') |

Thickness | 7.0,7.5,8.0,8.5,9.0,9.5,12,12.5 | |

Specifications Tolerance

| Length:±1.0MM, Width:±1.0MM, Thickness:±0.5MM

| |

Packing

| 6/8/10 pieces per carton with shrink wrap bag and importer trade mark printed on the carton strip.

| |

Max loaded details | 740/1350/1400 cartons,3239.40-4032 square meters,23.5 tons,loaded in one 20' FCL.

| |

B.Technical Data | 1..Weight/sqm:7.0MM:5.5KGS,7.5MM:5.7KGS,8.0MM:5.9KGS. 8.5MM:6.2KGS,9.0MM:6.8KGS,9.5MM:7.1KGS,12MM:9.2KGS, 12.5MM:9.5KGS. | |

2.Fire resistant property:No-flammable B1 in accordance with Chinese standard GB8624-1997 | ||

3.Lengthways & Lateral Ruptures Load:7.0MM>110N , 8.0MM>120N, 9.0MM>140N. | ||

Installation | Math with Top quanlity T-32/38 grids with 0.30-0.45MM thickness. | |

- Q:How to hollow ceiling production?

- After the shape of the ceiling, the installation of the inside of the lamp, the hollow carved board sticky white light glass, put it on the ceiling can be.

- Q:Gypsum board ceiling general shape how many square meters

- Accessories, steam nails nails, dry hanging nails, white latex, etc., more than 100 square meters, less than 2 yuan per square meter. Wages, the gap is relatively large, in general, an area of more than 100 square meters, flat top 40, modeling top (with light pool or bump shape) 60 square meters, if it is a large city may be higher. In summary, the gypsum board ceiling (single, no curve shape) cost is generally between 75-180 dollars, if the workers quote the profits on the float is about 30%

- Q:Light steel keel, gypsum board, T-type keel mineral wool board, aluminum-plastic plate, plastic gusset plate, soft film ceiling so much specific to use which okay?

- Plant span should be larger, easy to use light steel keel or aluminum alloy keel, construction attention to its force, cover with gypsum board, some fiberboard and so on.

- Q:What are the advantages and disadvantages of the fir board?

- Fir board although the price is low but the quality is not good, it is best not to use, the balcony area is more sunny area. In the long-term sunlight, the fir board is easy to crack.

- Q:It is fire resistant. Can the ceiling withstand the weight?

- The difference is 1/8 of an inch, and both have a fire rating, but 5/8' has a better rating.

- Q:Downstairs bedroom ceiling leakage, upstairs can not find the reason

- Ceiling (English name: sprung roof) refers to the housing living environment of the top decoration. Simply put, refers to the decoration of the ceiling, is an important part of interior decoration. Ceiling with insulation, insulation, sound insulation, sound absorption of the role, but also electrical, ventilation and air conditioning, communications and fire, alarm pipeline equipment and other projects hidden layer.

- Q:Two gypsum board ceiling is calculated by the square of the square or by gypsum board a square how much money?

- Two gypsum board ceiling calculation, to consider the difficulty of modeling, the number of labor and the number of latex paint and so on. Normally, the construction process for the double gypsum board + eyebrow paper paste + plaster + latex paint three times more complete. According to the projection area of the price, then about two square meters it.

- Q:3Dmax in the circular ceiling, gypsum line how to model?

- 1 first draw a circle (Circle) 2 draw a gypsum line section is the gypsum line line 3 Select Circle to select the Bevel Profile in the Edit editor 4 In the Bevel Profile there is a button that is the pick pick node (Pick Profile) pick up the intercept point (gypsum line line ) OK on the OK.

- Q:How is the roof of the steel roof?

- Steel roof is generally referred to the roof of the roof, this approach is not required to do hanging pendant. Of course, do not rule out the other decorative ceiling, generally do the ceiling are to do hanging pendant, hanging pieces directly welded door frame (steel beam, steel column) to form a hanging point.

- Q:My house decoration, ceiling in the end with gypsum board or aluminum plate is good? Home in the countryside, pay attention to is beautiful, practical, atmospheric, simple, beautiful and practical is the key, in the end how to choose? Two halls two bedrooms a store, the next three on the two, no kitchen.

- Gypsum board ceiling is generally used in the bedroom, living room and other dry and smoke-free environment, fear of water, and the surface brush latex paint, if dirty, not so easy to clean aluminum plate. Can be free to do all kinds of shapes, brush a variety of colors. Aluminum buckle plate is integrated ceiling, is the alloy material. Beautiful, but can not do a special shape, but the pattern has a variety of easy to clean up, are generally used in the kitchen. Suggest that you both use, can be used in a more appropriate place

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Faced Gypsum Board Ceiling Tiles

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 540000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords