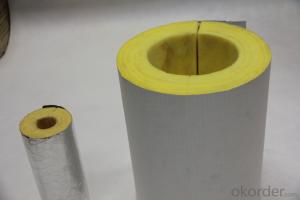

PVC faced Glass Wool Pipe for Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 700 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glasswool Pipes

1. Introduction

As this material ha s the characters of water-proof, anti-corrosion and mildewing-proof, glass wool pipe is good at stopping condensation and freezing of the pipes.

Technical Data

Item | Unit | Index |

Density | Kg/m3 | 48-96 |

Thickness | mm | 25-90 |

Diameter | mm | 18mm-529mm |

Length | mm | 1000,1200 |

Note: product with special specification can be made to order. Both unfaced and faced felts can be provided.

Image

2. Application

It is widely used in building, heating power pipes, air conditioning and refrigerors for thermal insurance, such as hot water pipes, steam pipes, electric power, petroleum and chemical industries. Glass wool pipe faced with Alum Foil can be applied to the surface for preventing moisture and radiation.

3. Package

Reasonable pieces will be packed with plastic bags or carton box, and then into container.

4. Our market

Our products sell well in Middle East, South East Asia, America and Europe. We have established good business relationship with the customers in over 120 countries and regions all over the world. We sincerely provide the highest quality products and the best services to friends from all over the world.

5.FAQ:

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance

- Q:What is the difference between anti-high temperature glass wool and ordinary glass wool?

- High-temperature glass wool is made of lathy glass fibers without shot. Compared with other kinds of insulation materials, it will not be broken due to water or rain, and it can still remain its insulation properties unchanged after drying in the sun (Thermal insulation materials have hydrophobicity which doesn’t mean that the materials are not hydrophilic but means that the discharge capacity for absorbed moisture). High-temperature glass wool is a thermal insulation material that can resist high temperature with its lightweight, lasting durability and excellent thermal insulation property, the material that is made up of uniform and slender and elastic glass fibers as well as special high-temperature adhesive. The outer protective layer of thermal insulation structure can use galvanized iron sheet based on specific circumstances. Application of high-temperature glass wool: It is widely used in equipment and pipelines of electric power, petroleum, chemical industry, light industry, metallurgy and other industries, serving as the thermal insulation.

- Q:Does rock wool board refer to the glass wool ?

- not

- Q:What's the difference between rock wool board, glass wool board, glass wool felt?

- 1, The main difference between rock wool and glass wool lies in withstanding temperature. Rock wool can withstand 650 degrees, but glass wool can withstand 300 degrees. Rock wool board can be used for building external wall thermal insulation, large petrifaction pipelines or tank thermal insulation, etc. Glass wool board is used for tanks at room temperature and piping insulation. Glass wool felt is used in middle of double steel roof. 2, Products in Hebei are mineral wool which is poor and not suitable for exporting, or you will lose worsely. 3,All are fireproof. 4, These materials are fiber products which are water funk. Add water repellent to form waterproof membrane on the fiber surface. Fiber can only absorb no water. It is impossible for fiber to be waterproof as it has many gaps. 5, Aluminum foil can be attached. Glass wool felt can be to be vacuumized to reduce the package volume and transportation cost.

- Q:Is centrifugal glass wool or rubber and plastic insualtion board better for air-conditioning air duct insualtion?

- Rubber and plastic insulation board is better.

- Q:Which has better effect of sound absorption, glass wool or rock wool?

- Glass wool rock wool has a security risk. It is easy to pulverize, so it may cause pruritus and respiratory allergies. PANHOO gradient sound absorption wool is the best in currently market, which is eco=friendly, healthy, most efficient in full-frequency sound absorption.

- Q:Glass wool can be used at zero degrees

- There are alkali superfine glass wool felt temperature: -100 ~ 450 ℃

- Q:Does rock wool refer to the glass wool?

- Rock wool is not glass wool, ~ ~ ~ two kinds of products, appearance, price, performance are different, have obvious difference.

- Q:Choosing glass wool with proper thickness for piping insulation of Dn900 boiler room.

- It depends on the temperature of pipes. Steam pipes with 300 degrees should choose the thickness of 100mm, which is based on the national standard that pipeline’ skin should keep less than or equal to 50 degrees in temperature. While hot water pipes keep 40 to 50mm in this regard.

- Q:Is the centrifugal glass wool board suitable for home use?

- Glass wool contact with the skin will be a little itch

- Q:These two kinds of glass wool are used as insulation materials, but one keeps 0.3 in specific gravity while the other keeps 0.5 in specific gravity. Which one should be chosen?

- It mainly depends on what would you use it for and what temperature of thermal insulation do you need. You can directly look through thermal insulation property of glass wool for further information. If you needs better thermal insulation effect, you can choose heavier specific gravity. If you are not so demanding, you can choose lighter ones.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC faced Glass Wool Pipe for Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m

- Supply Capability:

- 700 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords