PVC Electrical Tape With Flame Retardance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of PVC Electrical Tape With Flame Retardance

A thin premium grade plasticized PVC film coated with an aggressive rubber based adhesive with good characteristics. It is highly conformable and unaffected by most chemicals and moisture

Application of PVC Electrical Tape With Flame Retardance

Electric insulation below 600V; Insulating wrapping of electric wires and cables; Marking of electric wires and cables; Can be used indoors and out door

Available Size of PVC Electrical Tape With Flame Retardance

Paper Core ID: 76mm; 56mm; 38mm; 32mm

Jumbo Roll size: 1250mm x 33m

Cut roll size: 19mm x 10m; 19mm x 20m or as per customer's requirement

Cut rolls: Nine rolls in one plastic bag, placed in cartons, with or without pallet

Packing of PVC Electrical Tape With Flame Retardance

Jumbo rolls & log rolls: Packed with kraft paper and stretch wrap film, with or without pallet

Cut rolls: Shrink package, placed in cartons, with or without pallet

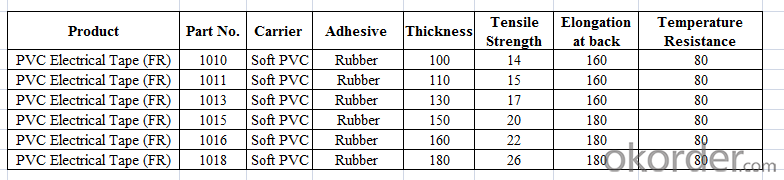

Technical Data of PVC Electrical Tape With Flame Retardance

Product Show of PVC Electrical Tape With Flame Retardance

FAQ: What are your company advantages?

Company Advantages:

1. Stable financial status and sound reputation as a state invested corporation under the direct administration of the State Council of PRC;

2. CNBM’s worldwide influence as one of the 500 global fortunes specializing in building materials including adhesive tapes;

3. More than a decade’s exporting experience and technology in adhesive tape industry;

4. Preferential shipping channels, with a separate team dealing with shipping.

- Q:Is packaging tape safe to use on mirrors?

- In general, using packaging tape on mirrors is considered safe. This tape is known for its strength and adhesive properties, which are intended to effectively hold objects in place. Nevertheless, it is crucial to consider the specific type of packaging tape being used, as it can impact the tape's safety when applied to mirrors. Opting for clear packaging tapes or tapes specially made for glass surfaces is typically the wisest choice in order to prevent any potential harm or residue on the mirror. Moreover, it is advisable to conduct a preliminary test on a small, inconspicuous area of the mirror to ensure proper adhesion and to avoid any potential damage.

- Q:Can packaging tape be used for sealing poly mailers?

- Yes, packaging tape can be used for sealing poly mailers. It provides a secure and durable seal that helps protect the contents of the poly mailers during transit.

- Q:Does packaging tape come in different lengths for convenience?

- Yes, packaging tape does come in different lengths for convenience.

- Q:Can packaging tape be used for sealing plastic garment bags?

- Yes, packaging tape can be used for sealing plastic garment bags. Packaging tape is designed to provide a secure and durable seal on various materials, including plastic. It can help keep the plastic garment bag tightly sealed, preventing dust, moisture, and other contaminants from entering the bag and potentially damaging or dirtying the garments inside. Additionally, packaging tape is typically easy to use, as it can be easily cut with a dispenser or a pair of scissors, making it convenient for sealing plastic garment bags.

- Q:What are the benefits of using transparent packaging tape?

- The benefits of using transparent packaging tape include clear visibility of the contents of the package, easy identification of any tampering or damage, professional appearance, and the tape's durability and strength for securing packages effectively.

- Q:Can packaging tape be used for heavy-duty packaging?

- Yes, packaging tape can be used for heavy-duty packaging. It is designed to provide strong adhesion and durability, making it suitable for securing and sealing heavy or bulky items during transportation or storage.

- Q:What are the common sizes of packaging tape?

- The common sizes of packaging tape typically range from 1.88 inches to 3 inches in width, while the length can vary depending on the brand and type of tape.

- Q:Can packaging tape be used for other purposes besides packaging?

- Yes, packaging tape can definitely be used for other purposes besides packaging. Due to its strong adhesive properties and durability, it can be used for a variety of tasks. For example, it can be used for household repairs such as fixing a broken book spine or securing loose cables. Additionally, it can be used for crafting projects like creating temporary or permanent decorations, making durable envelopes, or even in DIY projects like creating makeshift labels or organizing items. Furthermore, packaging tape can also be used for temporary fixes, such as sealing small leaks or cracks in pipes or containers until a permanent solution is found. The versatility of packaging tape makes it a handy tool to have around the house or office for various purposes beyond just packaging.

- Q:Can packaging tape be used for sealing packages with delicate fabrics or clothing?

- Yes, packaging tape can be used for sealing packages with delicate fabrics or clothing. However, it is important to exercise caution and take certain precautions to protect the delicate items. Here are a few tips to ensure safe packaging: 1. Use a wide, clear packaging tape: Opt for a wide tape that allows for a larger surface area of adhesion. Clear tape is preferable as it reduces the risk of leaving any visible residue or marks on the fabric. 2. Double-layer the tape: Apply two layers of packaging tape to provide extra strength and security to the package. This will help prevent the tape from accidentally peeling off during transit. 3. Wrap the delicate items securely: Before sealing the package, make sure to wrap the delicate fabrics or clothing in a protective layer, such as tissue paper or bubble wrap. This additional layer will act as a buffer and safeguard the items from any potential damage caused by the tape. 4. Avoid excessive tension: While sealing the package, be careful not to pull too tightly on the tape. Applying excessive tension may cause the fabric to stretch or distort, potentially damaging the delicate item. 5. Consider alternative options: If the delicate item is particularly fragile or valuable, it may be worth considering alternative packaging materials, such as acid-free tissue paper or garment bags. These options provide even more protection and are specifically designed for preserving delicate fabrics and clothing. Ultimately, while packaging tape can be used for sealing packages with delicate fabrics or clothing, it is essential to handle the items with care and take appropriate measures to minimize any potential damage during the packaging process.

- Q:What are the considerations for using packaging tape on glossy surfaces?

- When it comes to using packaging tape on glossy surfaces, it's important to keep a few key things in mind. First and foremost, the smoothness and slickness of the glossy surface can affect how well the tape sticks. The glossy finish creates a barrier that can make it difficult for the tape to adhere securely. That's why it's crucial to make sure the surface is clean and free from any dirt, oils, or residue that could prevent the tape from sticking properly. Choosing the right type of packaging tape is also important. Opting for a tape specifically designed for glossy surfaces, like high tack or acrylic adhesive tapes, can provide better adhesion and last longer. These tapes are specially formulated to stick well to smooth surfaces and create stronger bonds compared to regular packaging tape. It's also a good idea to test the tape on a small, inconspicuous area of the glossy surface before applying it everywhere. This will let you see how well the tape sticks and ensure that it doesn't leave any residue or damage the glossy finish when you remove it. Temperature and environmental conditions should also be taken into consideration. Extreme heat or cold can affect how well the tape performs on glossy surfaces. For example, high temperatures can cause the adhesive to soften, leading to the tape failing, while cold temperatures can make the tape more brittle and prone to peeling. Lastly, it's crucial to handle the glossy surface with care to avoid leaving fingerprints, smudges, or scratches that could detract from its appearance. Wearing gloves or using protective films can help prevent these issues. By keeping these factors in mind, you can enhance the effectiveness and reliability of packaging tape on glossy surfaces, ensuring that your packages are securely sealed without compromising the glossy finish's aesthetic appeal.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Electrical Tape With Flame Retardance

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20000 roll

- Supply Capability:

- 100000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords