PVC Decoration Panels Decoration Materials in China

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

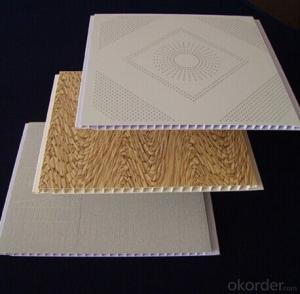

Product Applications:

Other companies claim their tiles/panels are washable (only temporarily) and some even claim to be waterproof, but only our tiles can be washed over and over, even a million times, and never be damaged. They are completely waterproof, will never grow mold and will never sag, bow, or bend due to humidity. They have a Class A flame spread and smoke developed index that's approved for all commercial kitchens and dining areas and can be used in any standard grid for drop ceilings. They are very decorative (not industrial looking) and are perfect for not only kitchens but offices, warehouses, food processing plants, clean rooms, bottling plants, and gymnasiums. Too numerous to name them all, so basically anywhere there is a drop ceiling our tiles will work great.

Product Advantages:

Thickness: 5mm, 7mm, 7.5mm, 8mm, 9mm or by request

Width: 10cm, 18cm, 20cm, 22cm, 24cm, 25cm, 38cm or by request

Length: Regular 5.95m, also as per your requirements.

pvc ceiling panels Features: Fireproof, waterproof, anti-warm and environment friendly,

For Ceiling and Wall decoration

Main Product Features:

4.Technical Data of gypsum ceiling tile:

Surface:High quality vinyl

Backside: Aluminum /PET (W&W/O)

Size Tolerance: length/width ≤±2.0mm

thickniss≤±0.5mm

Moisture Content: ≤ 3%

Density: 780KG/m³

Humidity resistant: ≥95%

NRC: 0.1-0.3

Light reflectant: 0.75

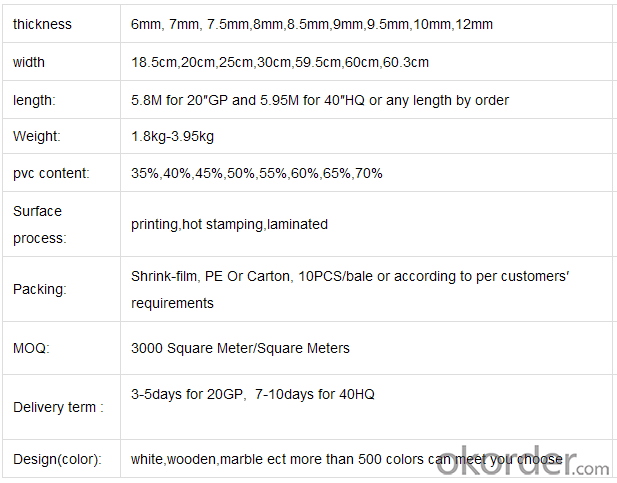

Product Specifications:

Images:

- Q:Pvc how to heat the deformation of soft board, to make their own shape

- The material is called thermoreversible crosslinking agent, also known as sodium dicyclopentadiene dicarboxylate, in the PVC processing process by adding 0.5%, can make PVC sheet or pipe heated to 50-60 degrees can be free deformation, if you want to return to the original state, but also Can be heated to the original state. This material has memory.

- Q:What is the difference between PVC board and oak board?

- PVC is a kind of plastic composite sheet, waterproof performance is good, cheap, easy to cut, the use of a very wide range of oak is a kind of wood material, waterproof performance is better, mainly harder than PVC, texture is good, but the price is Much more expensive than PVC, oak bathroom cabinet grade are generally higher.

- Q:Sun room,studded partition over the windows, pvc on the exterior. Losing heat? What can I do? Tiled roof?

- No hopefully I wouldn't be daft enough to do that. I don't have a sun roof but I can just imagine how stupid you would feel stuck there with no way out!

- Q:Pvc board and fire board glue what glue?

- What is the fire board material? What is the requirement of bonding? The general situation is to use Wan Nengjiao can, fixed time slightly longer, placed 24 hours. After the glue to the bubble (key point). If you know your request, you can specifically recommend your glue!

- Q:I use the PVC wall to do the backdrop, there are three square, one centimeter thick PVC board how to fix to the wall, is the use of glue or nails or other methods, with glue what is the glue. It is best to get their own home to the point of advice Thank you

- Fixed a lot of ways to use plastic bolts with plastic bolts ??? The most easy way to fight a few holes on the wall of a few holes with plastic plastic nail fixed nail surface decorated with a very beautiful hat

- Q:I have an old house and recent found a spot on my ceiling where there is a watermark. upon prodding through i see that the spot where the large cast iron drainage pipe that runs to the basement that connects to the 6 PVC bathroom drainage pipe upstairs has developed a small leak. There is a small spot where this white stuff (looks old) has chipped off and that is where the leak is coming from. Nothing major, but still a drip....drip....drip...enough to ruin the drywall, and enough to be fixed. I need to know what kind of material (pvc cement, caulk, etc) i would use to seal up that joint, as ripping it all out isnt an option. Something that preferrably would set when its wet (if possible) as it seems to be nonstop dripping.thanks for the help!

- The correct way to transist from existing cast iron female tapping to new pvc drain line is with a male pvc adapter. This fitting screws into cast iron fitting and has a female hub on the other end for pvc. Galvanized drain lines usually develop leaks at male threads. When a pipe is threaded the wall thickness is diminished at the thread and thinner. It is always best to eliminate all the galvanized drain line back to the larger cast iron drain if possible. This will eliminate any future galvanized drain problems.

- Q:PVC floor development prospects

- Market 1, into the time Since the 1980s, the first pvc plastic flooring has entered the domestic market since 2000, the whole industry is in the exploration and the initial stage, 1998-2004 PVC flooring has been the initial development, 2004 - 2007 PVC plastic sports flooring and commercial flooring gradually Has been recognized by the industry, more and more sports venues, venues began to use professional PVC sports floor, more and more construction projects have also begun to use PVC commercial flooring. With the 2008 Olympic Games held, as well as the entire market recognition of PVC plastic flooring. According to expert analysis of the industry has entered the development period. The next 5 to 10 years will enter a high-speed development period. 2, the demand for large According to the national development plan in 2017, the construction industry will become one of the pillar industries of the national economy, the state will build a house area of ??3.35 billion square meters in urban construction area of ??5 billion square meters, public buildings of about 1 billion square meters, The current foreign PVC flooring accounted for 1/3 ratio that this will be a huge market. Strong with PVC plastic flooring industry development. 3, the new high-tech floor materials PVC flexible plastic floor is the world's building materials industry's most innovative high-tech flooring materials. Is now widely used in foreign decoration works. (Schools, shopping malls, airports), education (schools, libraries, gymnasiums), pharmaceuticals (pharmaceutical plants, hospitals), factories and other industries are widely used, and made satisfactory (from the 80's to enter the domestic market has been vigorously promoted Effect, the use of increasing.

- Q:Acrylic board, Abs board and PVC board What is the difference, which can be cut with electric wire?

- Visual is to do COS props, right? Acrylic board has a special hook knife, you can also use their own one with a saw blade PVC board, then the general use of wire saws, utility knife can also need to practice. There is the PVC board grinding is indeed difficult, forced to use the edge of the need to polish the 502 quick-drying glue to make the surface hardened and then polished ~ must use a large number of coarse sandpaper.

- Q:Why do some people tell me when there is a lot of scratches on the color of the polished surface.

- PVC board after polishing the appearance of a color does not appear on the scratches, which is mainly because PVC its material surface is smooth, but the hardness and wear resistance and not, it is easy to scratch or grind scratches, but you It will be polished for polishing.

- Q:Pvc soft plate welding how to melt?

- Hot glue gun

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Decoration Panels Decoration Materials in China

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords