PVC Conveyor Belt Washboard Pattern Used in Sealing Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Conveyor Belt Washboard Pattern Used in Sealing Machine

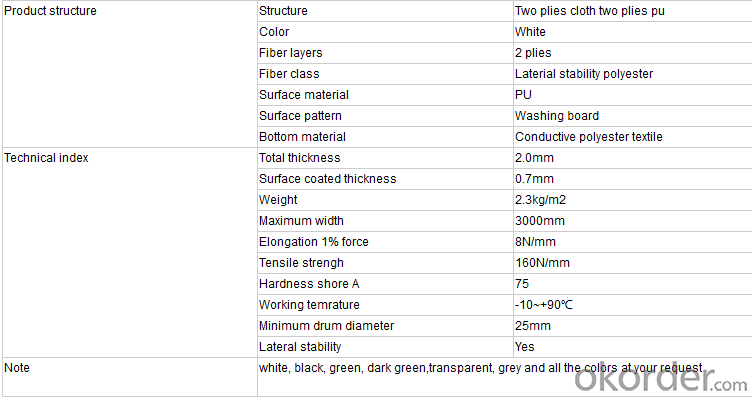

Product Description

Sealing machine washboard pattern pvc conveyor belt is widely used in the assembly lines in the areas of food processing,pharmaceutical,seafood processing industry sander machine ,seal machine(carton),medium density fiberboard(MDF board) production line,electronics,cigaratte,printing industry,etc.Product features hard wearing,good tensile strength and long service life.

Sealing machine washboard pattern pvc conveyor belt's using in food processing.It features lightness, thoughness,oil-resistant,nonpoisonous, sanitary and easy to clean.

PVC belts provide excellent acid and chemical resistance. A strong interwoven carcass of 100% polyester prevents ply delamination, allowing belt to wrap smaller pulley diameters. Carcass strength and design can provide a higher belt strength with a thinner belt gauge. PVC is available in a variety of strengths, colors, compounds, and cover styles to meet your exact requirement

Conveying specifications

On slider bed or rollers

Horizontal

Belt can be fitted with accessories ( flights, cleats, compart sidewalls, fingers)

Humid environment

Examples of industries

food processing,

pharmaceutical,

seafood processing industry

sander machine ,

seal machine(carton),

fiberboard(MDF board) production line,

electronics,cigaratte,printing industry

Additionnal information

Humid environment resistance

Antistatic top cover

Lightness

Low price

China supplier

Pvc material

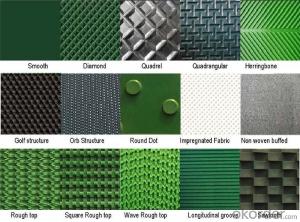

Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q:What can plastic particles do?

- 1, daily life, can be used to make all kinds of plastic bags, barrels, pots, toys, furniture, stationery and other living utensils and all kinds of plastic products.2, clothing industry: can be used to make clothing, neckties, buttons, zippers and so on.3. Building materials: can be used to make all kinds of building components, building tools, plastic doors and windows, mortar barrels, etc..

- Q:Electric kettle is plastic, okay?

- In addition, plastic electric kettle, only the outer shell is made of plastic, the liner is used in stainless steel, but the electric kettle in the heating process, the stainless steel liner temperature will become very high, the external plastic shell may appear a little taste in the heat, but this kind of the taste is very slight, generally do not produce what harm to the human body.

- Q:How do you prevent olive nets from causing damage to nearby structures or buildings?

- To prevent olive nets from causing damage to nearby structures or buildings, there are a few measures that can be taken. Firstly, ensuring that the nets are securely installed and properly tensioned is crucial. This will minimize the chances of the nets sagging or coming into contact with nearby structures. Additionally, regular inspection and maintenance of the nets is important to identify any potential issues, such as tears or loose attachments, which should be promptly repaired. Lastly, using protective padding or barriers between the nets and structures can provide an extra layer of protection against any accidental contact.

- Q:How do you prevent olive nets from getting tangled?

- To prevent olive nets from getting tangled, it is important to store them in a neat and organized manner. Rolling the nets tightly and securing them with clips or ties can help minimize tangling. Additionally, keeping the nets in a designated storage area away from other objects and potential obstructions can further prevent entanglement.

- Q:Can olive nets be used on olive trees grown in hydroponic systems?

- Yes, olive nets can be used on olive trees grown in hydroponic systems. Olive nets are commonly used in traditional olive tree cultivation to protect the fruits from pests and birds. In hydroponic systems, where olive trees are grown in a soilless environment, the use of olive nets can still serve the same purpose of protecting the fruits.

- Q:How to mend cracks in a plastic bucket?

- AB is a nickname for the two liquid mixed hardening glue, the glue is a liquid, a liquid hardener, two feed to hardening, is not required by the temperature should be hard ripening, so it is a kind of adhesive curing at room temperature, the model is sometimes used to do. Generally used in industry.

- Q:Do olive nets require any maintenance?

- Yes, olive nets require regular maintenance to ensure their effectiveness. They need to be regularly inspected for any damage or holes that may allow olives to escape. Additionally, they should be cleaned and stored properly after each use to prevent damage and prolong their lifespan.

- Q:Can olive nets be used for olive trees in regions with limited access to machinery?

- Yes, olive nets can be used for olive trees in regions with limited access to machinery. Olive nets are typically used to catch fallen olives during harvesting, regardless of the availability of machinery. They can be manually placed and secured beneath the olive trees, allowing for easy collection of the olives once they fall. This method is particularly suitable for regions where mechanical harvesters are not readily available or cost-effective.

- Q:White plastic products used for a long time will be yellow, how to do?

- Plastic products aging, color will increase, yellowing of plastic products can no longer be white.

- Q:What is cleaner for plastic bathtub?

- In fact, other methods of cleaning plastic items, plastic bathtubs can also be used, it is recommended that several methods of cleaning plastic objects, as long as it is plastic can be used1 put a few slices of lemon peel and orange peel in the glass, or drop a few drops of vinegar, then soak overnight.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Conveyor Belt Washboard Pattern Used in Sealing Machine

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords