PVC Conveyor Belt PU Conveyor Belt with Cleats

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Conveyor Belt PU Conveyor Belt with Cleats

Description:

The PVC conveyor belts are manufactured using high quality material.It features largely in the high strength, stable conveyance performance. Besides, it is fire retardant, anti-static, shock resistant, wearable and corrosion resistant. Our food conveyor belts are FDA/USDA approved and most types also have USDA Dairy Approvedand support your HACCP concept.

Features:

1. Non-Conductive

2. Anti-Static

3. Resistant to fats, chemicals, oil fat and abrasion

4. Various surfaces with high, medium and low coefficient friction

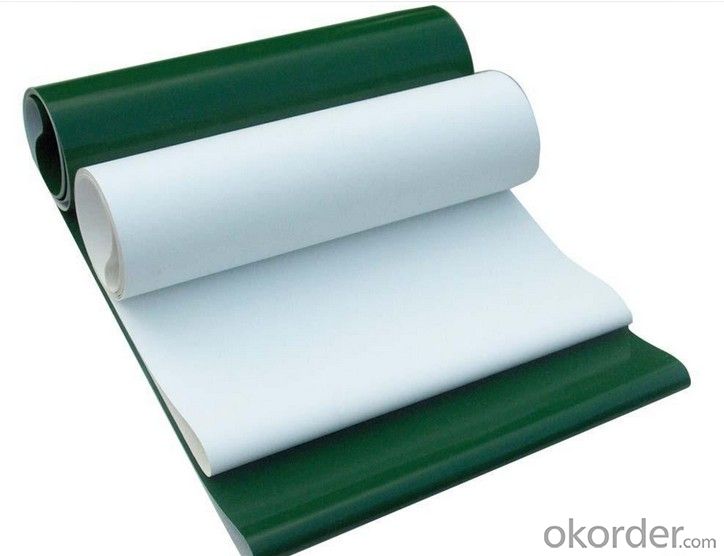

Thickness: PVC Belting (1~7mm) PU Belting (0.8~4mm)

Width: 200mm ~ 4000mm

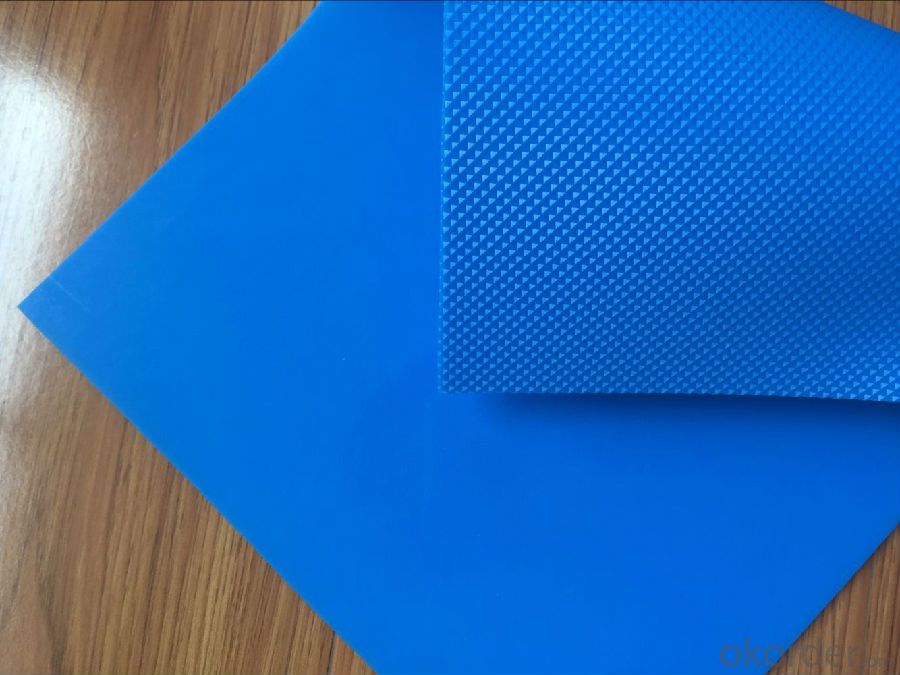

Appearance: Flat surface, diamond pattern, lawn pattern, golf pattern,etc.

Colors: Green, blue, gray, white, black, blue, dark green, transparent,etc.

Subsequent machining technology: It can add baffle, skirt, sponge, guide bar,etc.

Applications

PVC Conveyor belt has a wide range of products which can be applied in different industries, such as: tobacco, food, logistics, post, airport machinery, phamaceuticals, chemistry, electronics, printing, cable pulling, steel wrapping and sports entertainment.

Photos

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC/PU conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q:How much is plastic PP5 resistant to cold?

- The number 5 stands for PP plastic, or polypropylene plastic, non-toxic, tasteless and odorless, with a melting point of around 170

- Q:Can olive nets be used in olive groves with limited access to roads?

- Yes, olive nets can be used in olive groves with limited access to roads. Olive nets are typically lightweight and easy to transport, making them suitable for areas with limited road access. They can be carried by hand or using alternative modes of transport such as small vehicles or even by foot. Additionally, olive nets are designed to be easily installed and removed, allowing for efficient harvesting even in remote or hard-to-reach locations.

- Q:Can olive nets be used in small backyard olive tree gardens?

- Yes, olive nets can definitely be used in small backyard olive tree gardens. These nets are designed to protect the olives from birds and other animals that may try to eat them. By covering the tree with an olive net, you can ensure a higher yield of olives and protect them from any potential damage. Additionally, using olive nets in a small backyard garden can help to create a more controlled environment for the olives to grow, resulting in better quality fruit.

- Q:What is the ideal mesh size for an olive net?

- The ideal mesh size for an olive net is typically around 4-6 centimeters. This size allows for easy harvesting of olives while preventing smaller debris from getting tangled in the net.

- Q:Are olive nets easy to clean after use?

- Yes, olive nets are relatively easy to clean after use. They can be shaken or brushed to remove any debris or dirt, and then washed with water and mild soap if necessary.

- Q:Plastic molding is what to do, how the process?

- The choice of plastic molding is mainly determined by the type of plastic (thermoplastic or thermosetting), the starting form, and the shape and size of the product. The commonly used methods for processing thermoplastics are extrusion, injection molding, calendering, blow molding and thermoforming. Thermosetting plastics are generally molded, delivered and molded by injection molding. The plastic molding is various forms (such as powder, granules, solution and dispersion) of plastic products or parts required for the shape of. As many as 30 kinds of molding method. Lamination, molding and thermoforming are the processes of forming plastics on a flat surface. The plastic processing method can be used for rubber processing. In addition, there are liquid monomers or polymers as raw materials such as casting. In these methods, extrusion and injection molding are the most widely used and the most basic molding methods.

- Q:Can olive nets be used for both traditional and hydroponic olive tree harvesting?

- Yes, olive nets can be used for both traditional and hydroponic olive tree harvesting. Olive nets are commonly used to catch the olives as they are harvested from the tree, regardless of the cultivation method being employed. Therefore, whether the olive trees are grown in soil or in a hydroponic system, olive nets can still be effectively used to collect the harvested olives.

- Q:The lid of the vacuum cup is plastic. Will drinking water affect it?

- Plastic points are many, there is no harm to his face and asked to put into plastic, ceramic, glass or metal, the answer is the same, so can not be generalized;

- Q:Can olive nets be used to extend the harvesting season?

- Yes, olive nets can be used to extend the harvesting season. These nets are commonly used in olive orchards to catch and collect ripe olives as they fall from the trees, preventing them from being damaged or lost. By using olive nets, farmers can start harvesting earlier and continue harvesting for a longer period of time, effectively extending the harvesting season.

- Q:Can olive nets be used in combination with fertilization practices?

- Yes, olive nets can be used in combination with fertilization practices. Olive nets are primarily used to protect the olive trees from birds and other animals that may damage the fruit. Fertilization practices, on the other hand, aim to provide the necessary nutrients to the olive trees to promote healthy growth and maximize fruit production. By using olive nets in conjunction with fertilization practices, olive growers can ensure that the trees receive the required nutrients while safeguarding the fruit from potential harm.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Conveyor Belt PU Conveyor Belt with Cleats

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords