PVC Conveyor Belt PU Conveyor Belt Light Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Conveyor Belt PU Conveyor Belt Light Industry

Light Duty Conveyor Belts for food industry are excellent resistant to oil and fat, non-toxic, healthy and easy to clean. The type of belts conforms with FDA, USDA and EU regulations, can be used in many applications in the following industries: bakery, confectionary, meat and poultry, fish, fruit and vegetables, dairy, agriculture etc.

PVC/PU conveyor belt/FDA

1. material: PVC/PU

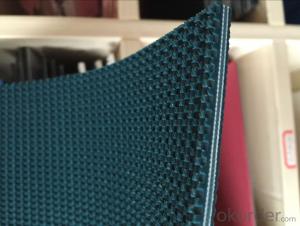

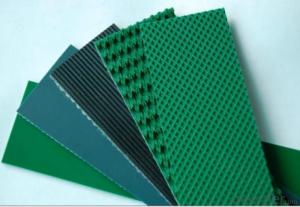

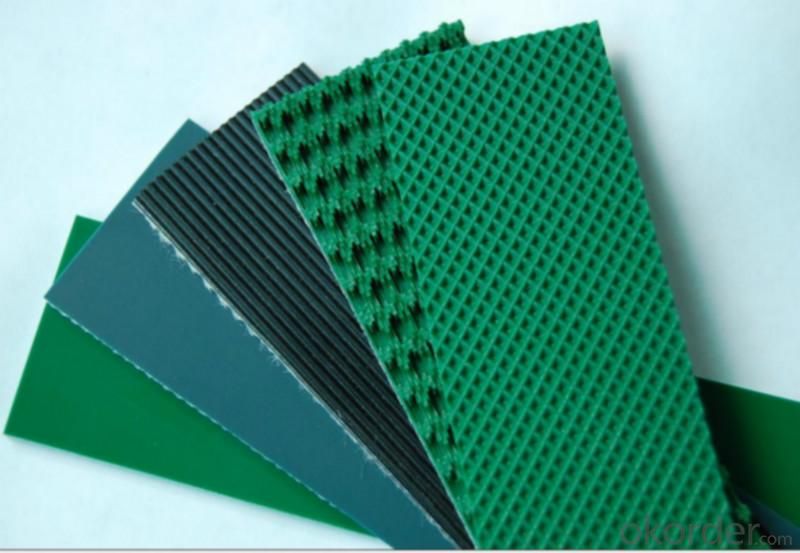

2. color: white,dark green,sky bule,etc

3. surface: smooth,matt

4. thickness:2mm/2.5mm/3mm/as request

PVC conveyor belt

No. of fabric plies:1, 2, 3, 4 ,5ply.

Surface:smooth,matt,diamond,rough,etc.

thickness:1mm-8mm

Thickness: 0.8-10mm

Width: 3000mm max

Length: 50-200m per roll.

Temperature: -20...+80℃

Color:white, green,blue,etc.

Features:

1)Low stretch;

2)Low maintenance;

3.Anti-static;

4)Flexible;

5.Lightweight;

6)Impervious to moisture,acids,oils,gases,sunlight;

7)Excellent fastener holding;

8)Excellent resistance to tearing,peeling and impact;

9)Endless belt splicing;

10)Special wear resistant edge design;

Product Photos

For more informations,please contact us freely,thank you.

- Q:Can olive nets be used on olive trees grown in vertical gardens?

- Yes, olive nets can be used on olive trees grown in vertical gardens. Olive nets are commonly used to protect the olives from birds and to aid in the harvesting process. Whether the olive tree is grown in a traditional orchard or a vertical garden, the nets can be installed to protect the olives and facilitate their collection.

- Q:Can olive nets be used to reduce pest infestations?

- Yes, olive nets can be used to reduce pest infestations. These nets are commonly used in agriculture to protect olive trees and fruits from various pests such as insects and birds. The nets create a physical barrier, preventing pests from reaching the trees or fruits, thus reducing the likelihood of infestations.

- Q:How does an olive net work?

- An olive net works by being spread out underneath olive trees to catch the falling olives during harvest. The netting prevents the olives from touching the ground, keeping them clean and undamaged. Once the olives fall onto the net, they can be easily collected and removed, making the harvesting process more efficient.

- Q:Can olive nets be used in areas with high bird populations?

- Yes, olive nets can be used in areas with high bird populations. Olive nets are designed to protect olive trees and their fruits from birds and other pests. They are made of tightly woven materials that prevent birds from accessing the trees and damaging the olive crops. However, it is important to note that no netting is 100% foolproof, and some determined birds may still find their way through or around the nets. Therefore, additional bird deterrents or management strategies may be required to effectively control bird damage in areas with high bird populations.

- Q:Are olive nets easy to maintain?

- Yes, olive nets are generally easy to maintain. They require regular cleaning to remove any debris or fallen olives, and occasional repairs or replacement of damaged sections. Overall, with proper care and attention, olive nets can be easily maintained.

- Q:Can olive nets be used on olive trees grown in windy areas?

- Yes, olive nets can still be used on olive trees grown in windy areas. However, it is important to ensure that the nets are properly secured to withstand strong winds. Additionally, selecting a net with a smaller mesh size can help prevent wind damage to the olive trees and improve overall effectiveness.

- Q:Can olive nets be customized for specific orchard layouts?

- Yes, olive nets can be customized to accommodate specific orchard layouts. Different sizes, shapes, and configurations can be tailored to fit the specific needs and dimensions of an orchard, ensuring optimal coverage and protection for the olive trees.

- Q:How do olive nets prevent olives from getting sunburned?

- Olive nets prevent olives from getting sunburned by providing shade and reducing direct exposure to the intense sunlight, thus protecting the delicate fruit from heat stress and sun damage.

- Q:Are there any specific guidelines for removing olive nets without damaging the trees?

- Yes, there are specific guidelines for removing olive nets without damaging the trees. Some recommended practices include: 1. Begin by removing any debris or branches that have accumulated on the net. 2. Slowly and carefully lift the net from the edges, ensuring that it doesn't catch on any branches or twigs. 3. Avoid pulling or tugging on the net aggressively, as this can cause damage to the olive tree. 4. If the net is tightly tangled around branches, carefully untangle it or cut it away using a pair of sharp scissors or pruning shears. 5. Take extra care while removing the net from around the trunk, as this is a sensitive area that can be easily damaged. 6. Once the net is completely removed, inspect the tree for any signs of damage or stress, and take appropriate measures if necessary, such as pruning or treating any wounds. By following these guidelines, olive nets can be safely removed without causing harm to the trees.

- Q:How do olive nets prevent fungal damage to olives?

- Olive nets prevent fungal damage to olives by providing a physical barrier that blocks the entry of fungal spores. These nets act as a shield, preventing the spores from coming into contact with the olives and reducing the risk of fungal infections. Additionally, the nets promote better air circulation and sunlight exposure, creating an unfavorable environment for fungal growth.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Conveyor Belt PU Conveyor Belt Light Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords