PVC Conveyor Belt Green Diamond 3.0mm For Light Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

PVC Conveyor Belt Green Diamond 3.0mm For Light Industry

We can divide the conveyor belt into three categories: PVC conveyor belt, PU conveyor belt and some special material, such as silica gel, rubber.

conveyor belt fabric layers: A layer of cloth and a layer of glue, two layers of cloth and two layers of glue, three layers of cloth and three layers of glue, and so on. It can be customized according to your requirements.

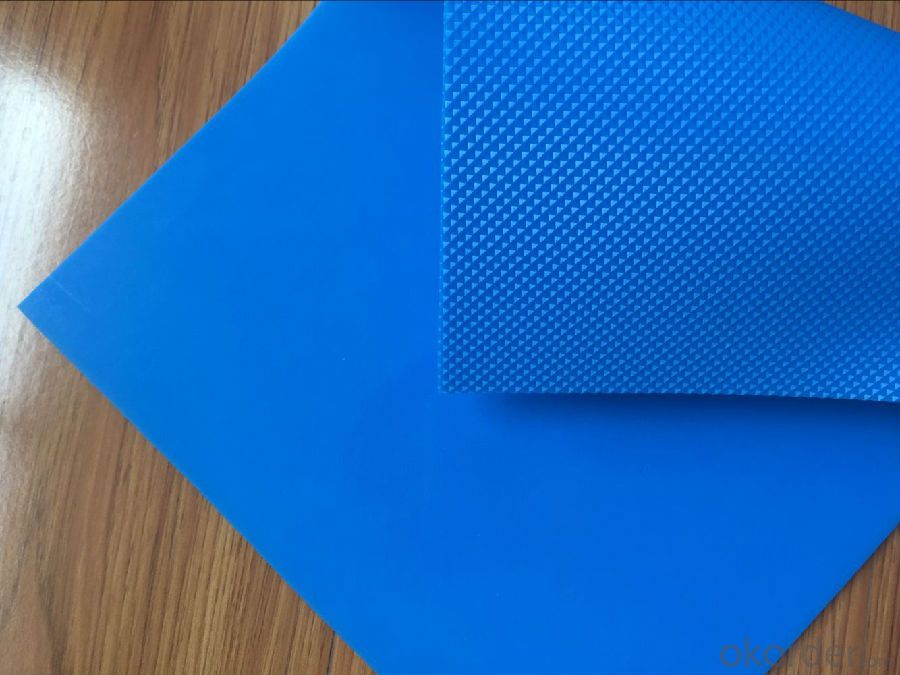

Colors: red, yellow, green, blue, gray, white, black, blue, green, transparent (in general we have)

Thickness: PVC (1~7mm) PU (0.8~4mm)

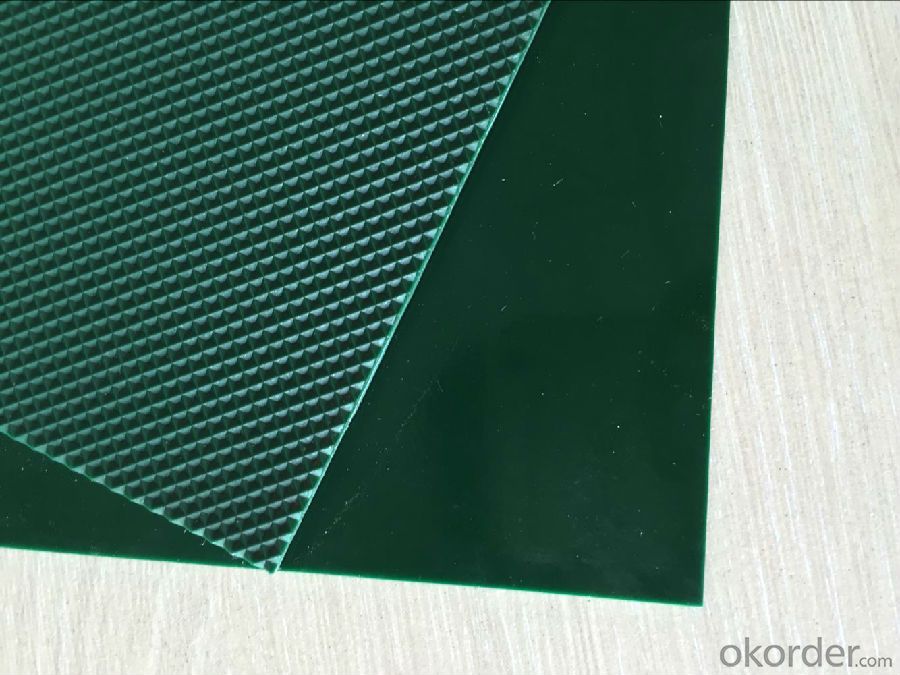

Appearance: flat surface, diamond pattern, lawn pattern, golf pattern etc.

Advantages: PVC: economical and practical, technology is mature.

PU: applicable to the food industry, abrasion resistant and corrosion.

Subsequent machining technology: it can add baffle, skirt, sponge, guide bar.

Feature PVC Conveyor Belt:

*Anti-static and non-conductive

*Food quality types to FDA standards

*Resistance to abrasion, oils, fats and chemicals

*Surfaces with low, medium or high coefficient of friction

*High transverse rigidity and dimensional stability

* Low noise (LdB belts)

* Working temperature ranges from -10 to 80Deg.C

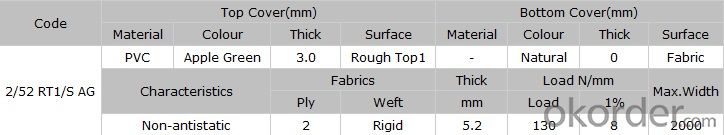

PVC Conveyor Belt Specifications

Photos of PVC Conveyor Belt

FAQ

Q: Can you do OEM?

A: Yes, we can do OEM products. It's no problem.

Q: How can I get some samples?

A: 1, We are honored to offer you samples. New clients are expected to pay for the courier cost, the samples are free for you, this courier cost charge will be deducted from the payment for formal order.

2, Regarding the courier cost: you can arrange a RPI (remote pick-up) service upon Fedex, UPS, DHL, TNT, etc. to have the samples collected; or inform us your DHL collection account. Then you can pay the freight direct to your local carrier company.

Q: How do you do regarding quality control?

A: Quality is priority? We always attach great importance to quality controlling from the very beginning to the very end:

1).All raw material we used are environmental-friendly;

2).Skilful workers care every details in handling the producing and packing processes;

3).Quality Control Department specially responsible for quality checking in each process.

Q.What are your payment terms?

A: Standard payment terms are 30%T/T,and balance upon the B/L copy .

L/C at sight is acceptable

Other payment terms can be negotiable.

If you want to find more details about the PVC conveyor belt, you could make an Inquiry in okorder.com. Okorder.com provides you the products with best price and quality!

- Q:Can olive nets be used to reduce nutrient deficiencies?

- No, olive nets are primarily used for protecting olive trees and collecting olives during harvest, and they do not have any direct impact on reducing nutrient deficiencies in plants or humans. Nutrient deficiencies are typically addressed through proper soil management, fertilization, and dietary interventions.

- Q:Can olive nets be used in areas with frequent wildfires?

- No, olive nets should not be used in areas with frequent wildfires as they can potentially increase the risk of fire spread and pose a safety hazard. It is important to prioritize fire safety measures in such areas.

- Q:Can olive nets be used to increase yield?

- Yes, olive nets can be used to increase yield. By placing nets under olive trees, they help catch falling olives during harvesting, reducing fruit loss and increasing overall yield. The nets also provide shade, preventing sunburn on the fruit and improving their quality. Additionally, nets can protect the olives from birds and other pests, further enhancing the yield.

- Q:How long does an olive net typically last?

- The lifespan of an olive net typically depends on various factors such as the quality of the material used, the frequency of use, and the level of maintenance. On average, a well-maintained olive net can last anywhere from 5 to 10 years.

- Q:Can olive nets be used in different climates?

- Yes, olive nets can be used in different climates. Olive nets are designed to protect olive trees from pests, birds, and wind. They are made from durable materials that can withstand various weather conditions, including hot summers, cold winters, and rainy seasons. Additionally, olive nets are versatile and can be easily adjusted or modified to suit different climate needs, such as adjusting the mesh size or adding additional layers for extra protection.

- Q:Can olive nets be used for olive tree rejuvenation?

- No, olive nets cannot be used for olive tree rejuvenation. Olive nets are typically used for harvesting olives by preventing them from falling to the ground. Rejuvenation of olive trees involves specific pruning and fertilization techniques to stimulate new growth and improve the overall health and productivity of the tree.

- Q:How does an olive net affect the overall erosion control in the olive grove?

- An olive net can significantly improve erosion control in an olive grove. By covering the ground beneath the trees, the net prevents soil erosion caused by heavy rainfall or strong winds. It also helps retain moisture in the soil, reducing water runoff and promoting healthy root growth. Additionally, the net acts as a barrier, preventing soil compaction and protecting the topsoil from being washed away. Therefore, the overall effect of an olive net is to enhance erosion control and maintain the stability and productivity of the olive grove.

- Q:What are the different materials used to make olive nets?

- The different materials used to make olive nets include nylon, polyethylene, and polypropylene.

- Q:What materials are olive nets made from?

- Olive nets are typically made from lightweight and durable materials such as high-density polyethylene (HDPE) or polypropylene.

- Q:Where can you purchase olive nets?

- You can purchase olive nets at agricultural supply stores, online marketplaces, or directly from olive equipment suppliers.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Conveyor Belt Green Diamond 3.0mm For Light Industry

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords