PVC Coated/galvanized Welded Wire Mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

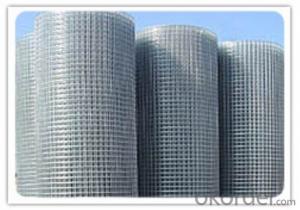

welded wire mesh

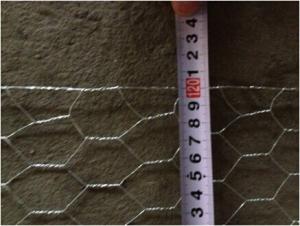

1.Diameter: 0.4-3mm (Roll )

2.Mesh Hole:1/4''--2''(Roll)

3.High quality

4.Rich export experience

1.Welded wire mesh detail information and Specification:

*Welded wire mesh material

Mild steel wire, stainless steel wire, galvanized steel wire, hot-dipped zinc plating iron wire

*Welded wire mesh Surface treatment

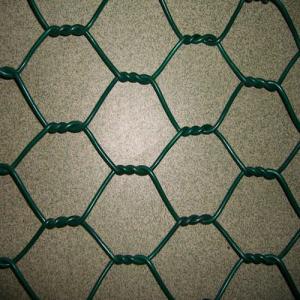

Hot dipped galvanized, electro galvanized, PVC coate

*Welded wire mesh Color:green,blue,black,silvery,etc,

*Welded wire mesh Finish: Electric galvanizing, hot-dip zinc plating, stainless steel or PVC coated

*Welded wire mesh Classification:

•Stainless steel wire welded wire mesh

•Electro or hot dipped galvanized after or before welded

•PVC coated welded wire mesh

•Black wire or without coated welded wire mesh

*Welded wire mesh roll Specification:

opening |

Wire Diameter<BWG> | |

In inch | In metric unit(mm) | standard |

1/4"×1/4" | 6.4mm×6.4mm | 22,23,24 |

3/8"×3/8" | 10.6mm×10.6mm | 19,20,21,22 |

1/2"×1/2" | 12.7mm×12.7mm | 16,17,18,19,20,21,22,23 |

5/8"×5/8" | 16mm×16mm | 18,19,20,21 |

3/4"×3/4" | 19.1mm×19.1mm | 16,17,18,19,20,21 |

1"×1/2" | 25.4mm×12.7mm | 16,17,18,19,20,21 |

1-1/2"×1-1/2" | 38mm×38mm | 14,15,16,17,18,19 |

1"×2" | 25.4mm×50.8mm | 14,15,16 |

2"×2" | 50.8mm×50.8mm | 12,13,14,15,16 |

*Welded wire mesh panel Specification:

| Wire diameter(mm) | Vertical spacing(mm) | Horizontal spacing(mm) | Length(m) | Width(m) |

| 10 | 100-500 | 30-300 | 1-8 | 0.5-3 |

| 9 | 100-500 | 30-300 | 1-8 | 0.5-3 |

| 8 | 100-500 | 30-300 | 1-8 | 0.5-3 |

| 7 | 50-200 | 20-300 | 1-8 | 0.5-3 |

| 6 | 50-200 | 20-200 | 1-8 | 0.5-3 |

| 5 | 50-200 | 10-200 | 1-8 | 0.5-3 |

| 4 | 30-200 | 10-200 | 1-8 | 0.5-3 |

| 2-4 | 25-100 | 10-100 | 1-6 | 0.5-3 |

| 1 | 33 | 15-80 | 2.2 | 28 |

2.Welded wire mesh welding style:

Welded wire mesh, galvanized before weaving

Welded wire mesh, galvanized after weaving

Welded wire mesh, thermal electroplated

Welded wire mesh, PVC coated

carbon steel wire welded into a network → heating → cooling to the required temperature

4.Welded Wire Mesh Features

Made of high quality low carbon steel wire.

Various colors and sizes.

Range of sizes to suit roadway width and bolting patterns.

Easy installation

5.Welded Wire Mesh Application

Welded wire mesh is widely used in industry and agriculture building

Egg baskets, pet cages

Runway enclosures

1. Payment:

1) TT, 30% deposit , 70% before shipment.

2) TT, 30% deposit, 70% L/C at sight or 100% by L/C at sight. (high bank charge,

not suggest , but acceptable)

3) 100% Western Union in advance. (specially small amount)

2. Delivery:

1) Generally by ship. 2) By express or air. (small quantity of sample order)

- Q:What is the barbed wire in the cable line?

- Some good quality line, in addition to the shielding network, but also wrapped in this layer of gold-plated film, its role is shielding.

- Q:Is it possible to protect the radiation around the computer with a wire mesh?

- I have not heard of the wire, the chassis cover is the original radiation ah. Just do not advocate bare metal battle (no chassis or 24 hours cover)

- Q:What is the role of wire in the wire

- Protection and shielding effect of the outermost glue is insulated, fire effect. Some inside there will be iron / copper layer, is the protection and shielding effect.

- Q:Why do you want to shop a barbed wire?

- Finally, after the core wall of the cement touched, with the level of correction that looks very flat, so whether it is from the aesthetic level or practical

- Q:How does the "jagged" on the back of the knife cut the barbed wire?

- Army knife sawtooth is mainly to eliminate the internal strength of the knife body, processing to be quenched, there are jagged, quenching time to eliminate the knife's internal stress, is more solid knife body, and in special times as a saw, do not have to cut wire mesh,

- Q:Will the gray sand brick wall is full of hanging wire mesh?

- Do not cover, mainly the block and concrete frame at the junction to hang 300mm wide steel wire mesh, barbed wire is in the bearing beam, column with the late brick between the wall of the nail,

- Q:This material of the barbed wire in the water I do not know how long?

- Protection and shielding effect of the outermost layer of glue is insulated, the role of fire inside some iron / copper layer, is the protection and shielding effect of the innermost copper wire, is the current effect, used for conductive transmission

- Q:Is the warm tube laid on top of the steel wire or below?

- on the maintenance of the warm tube I told you to see what you use the pipe to decide, if the use of high temperature polyethylene PE-RT material, then you can use a dedicated interface to hot-melt connection to repair, if used Is the coach polyethylene PE-X pipe, then it is difficult to deal with,

- Q:Barbed wire fence is what the iron ring

- Thorns are divided into ordinary wire and barbed wire. Surface treatment process: electro-galvanized, hot-dip galvanized, plastic, spray

- Q:Wire mesh for wire mesh applications

- The current barbed wire Uses: used for coal mountain, mining, construction, breeding, glass, oil, metal products, petrochemical, construction machinery, protective net, barbecue net, crafts net, food machinery net,

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Coated/galvanized Welded Wire Mesh

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords