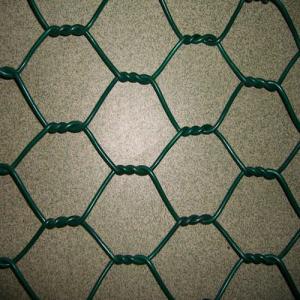

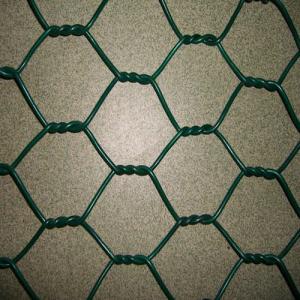

PVC Coated Chain Link Fence

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Type: | Place of Origin: | Hole Shape: | |||

| Model Number: | Frame Material: | Metal Type: | |||

| Pressure Treated Wood Type: | Frame Finishing: | Feature: | |||

| Item: | Material: | Assortment: | |||

| Mesh: | Wire dia: | Length: | |||

| Height: | zinc coating: | Color: | |||

Packaging & Delivery

| Packaging Detail: | woven bags in two edge of rolls |

| Delivery Detail: | 15-25days |

Specifications

Chain link fence

1.Material: low carbon steel wire,stainless steel wire, PVC coated wire.

2.Wire dia 0.2mm~5.0mm

- Q:How durable is steel wire mesh?

- Steel wire mesh is known for its high durability. It is specifically designed to withstand heavy loads, resist corrosion, and maintain its structural integrity over time. The durability of steel wire mesh depends on various factors such as the thickness of the wire, the size of the mesh openings, and the type of steel used. Generally, steel wire mesh is highly resistant to impact, abrasion, and extreme weather conditions, making it suitable for a wide range of applications. It can be used in construction, agriculture, mining, fencing, and various industrial settings where strength and longevity are crucial. With proper maintenance and regular inspections, steel wire mesh can last for many years, providing a reliable and robust solution for different requirements.

- Q:What are the different mesh counts available in steel wire mesh?

- Steel wire mesh comes in various mesh counts, indicating the number of openings or holes per linear inch. The available mesh counts for steel wire mesh can differ significantly depending on the specific use and desired level of filtration or screening. Typical mesh counts for steel wire mesh range from as low as 2 mesh (equivalent to 2 openings per linear inch) to as high as 400 mesh (equivalent to 400 openings per linear inch). The selection of mesh count is usually based on the size of particles or materials that need to be filtered or screened. For instance, larger mesh counts like 2 mesh or 4 mesh are suitable for heavy-duty applications that require coarse filtration or screening, as seen in the mining or construction industries. On the contrary, finer mesh counts such as 100 mesh or 200 mesh are employed for more precise applications where a finer level of filtration or screening is necessary, like in the pharmaceutical or food processing industries. It's essential to recognize that mesh counts can also differ in terms of wire diameter and opening size. Having a higher mesh count doesn't necessarily mean smaller openings, as the wire diameter and opening size can affect the overall effectiveness of the mesh. As a result, it is crucial to consider both the mesh count and other specifications of the steel wire mesh to ensure it meets the requirements of the specific application.

- Q:Can steel wire mesh be used for signage?

- Yes, steel wire mesh can be used for signage. It provides a durable and versatile material for creating unique and eye-catching signs. The mesh allows for creative designs and can be easily customized to fit specific branding or messaging needs. Additionally, steel wire mesh is weather-resistant, making it suitable for both indoor and outdoor signage applications.

- Q:How is steel wire mesh used in reinforcement of chemical and petrochemical facilities?

- Steel wire mesh is commonly used in the reinforcement of chemical and petrochemical facilities due to its exceptional strength and durability. These facilities often deal with harsh and corrosive environments, which require materials that can withstand extreme conditions. In chemical and petrochemical facilities, steel wire mesh is primarily used for reinforcement in concrete structures. Concrete is a widely used construction material due to its high compressive strength, but it lacks tensile strength. By incorporating steel wire mesh into concrete structures, it helps to enhance the overall strength and structural integrity. Steel wire mesh is typically embedded within the concrete to form a reinforcing grid. This grid acts as a reinforcement system, distributing the load evenly across the structure and preventing cracks or failures. The mesh reinforces the concrete by resisting tensile forces and providing stability, especially in areas prone to high stress or potential impact. Moreover, steel wire mesh is highly resistant to corrosion, making it an ideal choice for chemical and petrochemical facilities. The exposure to various chemicals, high temperatures, and moisture in these facilities can cause significant damage to the reinforcement materials. However, steel wire mesh has excellent corrosion resistance properties, ensuring long-term durability and structural stability. Additionally, steel wire mesh can be customized to meet specific requirements, such as different mesh sizes and wire diameters. This versatility allows engineers and contractors to design and reinforce structures based on the specific needs of the chemical and petrochemical facilities. Overall, the use of steel wire mesh in the reinforcement of chemical and petrochemical facilities provides numerous benefits, including increased strength, durability, and corrosion resistance. It plays a crucial role in ensuring the safety and longevity of these facilities in challenging environments.

- Q:How is steel wire mesh used in reinforcement of concrete columns?

- Steel wire mesh is used in the reinforcement of concrete columns by providing additional tensile strength to the structure. The mesh is placed within the concrete during the pouring process, and it helps to prevent cracking and improve the overall durability and load-bearing capacity of the columns.

- Q:Is steel wire mesh suitable for use in wastewater filtration systems?

- Yes, steel wire mesh is suitable for use in wastewater filtration systems. It is highly durable, resistant to corrosion, and can effectively trap and remove solid particles from wastewater. Additionally, its strength allows for high-pressure filtration processes, making it an ideal choice for wastewater treatment applications.

- Q:Can steel wire mesh be used for ventilation purposes?

- Yes, steel wire mesh can be used for ventilation purposes. Steel wire mesh is a versatile material that can effectively allow air to pass through while providing a barrier to prevent the entry of unwanted pests, debris, or larger particles. It can be used in various applications such as window screens, air vents, HVAC systems, or even as a protective cover for machinery or equipment that requires airflow. The fine openings in the mesh allow air circulation, ensuring proper ventilation in the desired area while maintaining security and protection. Steel wire mesh is durable, fire-resistant, and can withstand harsh weather conditions, making it suitable for both indoor and outdoor ventilation needs.

- Q:What is the barbed wire fence? What is the general specification?

- The appropriate bending, creating a unique aesthetic effect of this product, and the surface can be used in a variety of colors of the dipping treatment, columns and mesh with different colors is pleasing to the eye, while the use of such products with a chassis

- Q:Can steel wire mesh be used for greenhouse structures?

- Certainly, greenhouse structures can make use of steel wire mesh. Steel wire mesh proves to be a versatile material with a wide range of applications, including greenhouse structures. Its strength and durability allow it to withstand even the harshest weather conditions, making it an ideal choice for constructing a greenhouse. Furthermore, the wire mesh not only provides the necessary structural support but also allows for ample airflow and sunlight penetration, which are crucial for optimal plant growth. Moreover, steel wire mesh is resistant to rust and corrosion, ensuring the longevity of the greenhouse structure. In conclusion, due to its strength, durability, and ability to create a favorable environment for plant cultivation, steel wire mesh stands as a reliable option for greenhouse construction.

- Q:Is steel wire mesh suitable for use in automotive airbag systems?

- Steel wire mesh is not suitable for automotive airbag systems because it is heavy, rigid, and lacks the necessary flexibility for proper deployment and protection during collisions. Furthermore, it does not offer the same level of impact absorption as other materials used in airbag systems, which may compromise the safety of vehicle occupants. Therefore, alternative materials like nylon or polyester fabric are commonly utilized in automotive airbag systems due to their lightweight, flexible, and high tensile strength properties.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Coated Chain Link Fence

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords