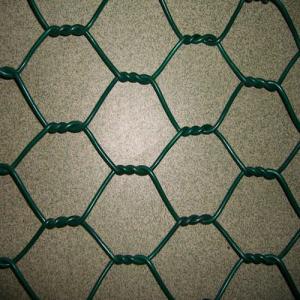

PVC Coated Chain Link Fence With Hot Dipped Galvanized Wire Inside

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Type: | Place of Origin: | Hole Shape: | |||

| Model Number: | Frame Material: | Metal Type: | |||

| Pressure Treated Wood Type: | Frame Finishing: | Feature: | |||

| Item: | Material: | Assortment: | |||

| Mesh: | Wire dia: | Length: | |||

| Height: | zinc coating: | Color: | |||

Packaging & Delivery

| Packaging Detail: | woven bags in two edge of rolls |

| Delivery Detail: | 15-25days |

Specifications

Chain link fence

1.Material: low carbon steel wire,stainless steel wire, PVC coated wire.

2.Wire dia 0.2mm~5.0mm

- Q:Is steel wire mesh suitable for use in mining operations?

- Yes, steel wire mesh is suitable for use in mining operations. Steel wire mesh is a versatile material that offers several benefits for mining operations. Firstly, steel wire mesh is incredibly strong and durable, making it suitable for use in rugged and demanding mining environments. It can withstand heavy loads, impacts, and abrasion, ensuring long-lasting performance. Secondly, steel wire mesh provides excellent resistance to corrosion, which is crucial in mining operations where the presence of moisture, chemicals, and other corrosive substances is common. This resistance to corrosion helps extend the lifespan of the mesh, reducing the need for frequent replacements. Moreover, steel wire mesh offers high tensile strength, allowing it to withstand extreme tension without breaking or deforming. This property is essential in mining operations where the mesh is often subjected to heavy loads and pressure. Additionally, steel wire mesh is highly versatile, as it can be easily customized to fit specific mining applications. It can be fabricated into various shapes and sizes to meet the specific requirements of different mining operations, ensuring optimal efficiency and safety. Lastly, steel wire mesh is cost-effective compared to other materials commonly used in mining operations. Its durability and long lifespan reduce maintenance and replacement costs, making it a cost-efficient choice for mining companies. In conclusion, steel wire mesh is a suitable material for use in mining operations due to its strength, durability, corrosion resistance, versatility, and cost-effectiveness. It can withstand harsh mining environments, ensuring optimal performance, safety, and cost savings for mining companies.

- Q:Can steel wire mesh be used for dewatering applications?

- Indeed, dewatering applications can make use of steel wire mesh. Given its robustness, endurance, and resistance against corrosion, steel wire mesh is frequently employed in diverse industrial procedures, including dewatering. It effectively segregates solid particles from liquids, permitting the fluid to flow through while retaining the solids. To cater to different dewatering needs, steel wire mesh screens can be woven with varying aperture sizes. Moreover, the mesh can be effortlessly cleaned and upheld, rendering it an economical choice for dewatering applications in sectors like mining, construction, wastewater treatment, and agriculture.

- Q:Can steel wire mesh be used for moisture control?

- Steel wire mesh can be used as a component in moisture control systems. While it may not directly control moisture, it can be used in various applications to support moisture control efforts. For example, steel wire mesh can be used as a reinforcement in concrete structures such as retaining walls or foundation slabs, which can help prevent moisture infiltration. Additionally, steel wire mesh can be used in drainage systems to facilitate the flow of excess moisture away from structures. Furthermore, steel wire mesh can also be used as a barrier or protective cover to prevent moisture from entering certain areas, such as crawl spaces or ventilation systems. However, it is important to note that steel wire mesh alone is not a complete solution for moisture control and should be used in conjunction with other appropriate measures for effective moisture management.

- Q:How is steel wire mesh used in reinforcement of agricultural projects?

- Steel wire mesh is commonly used in the reinforcement of agricultural projects as it provides strength and stability to structures such as fences, cages, and enclosures. It is often used to create durable and secure boundaries for livestock and crops, preventing them from wandering off or being damaged by external forces. Additionally, steel wire mesh can be used to support climbing plants or create trellises, allowing for efficient use of vertical space and promoting healthy growth. Overall, the use of steel wire mesh in agricultural projects enhances the efficiency and effectiveness of farming practices while ensuring the safety and protection of crops and livestock.

- Q:How is steel wire mesh used in the mining industry?

- Steel wire mesh is widely used in the mining industry for a variety of applications. One of the primary uses of steel wire mesh in mining is for safety purposes. It is commonly used to create barriers and fences around mine shafts, open pits, and other hazardous areas to prevent unauthorized access and protect workers from potential accidents. In addition to safety, steel wire mesh is also utilized for sieving and filtering purposes in the mining industry. It is commonly used as a screen or sieve to separate and classify different sizes of minerals, rocks, and ores during the mining process. This helps in the efficient extraction and processing of materials, ensuring that only the desired particles are collected and further processed. Furthermore, steel wire mesh is used in mining for reinforcement and support purposes. It is often installed as a mesh lining in tunnels, underground mines, and other excavations to provide structural stability and prevent the collapse of surrounding rocks and soil. This reinforcement helps to maintain the integrity of the mining infrastructure and ensures the safety of workers and equipment. Moreover, steel wire mesh is also utilized for ventilation purposes in the mining industry. It is installed as ventilation screens or ducting covers to allow the flow of fresh air into underground mines and remove harmful gases and dust. Proper ventilation is crucial for maintaining a safe and healthy working environment for miners. Overall, steel wire mesh plays a vital role in the mining industry by providing safety barriers, facilitating sieving and filtering, reinforcing structures, and enabling proper ventilation. Its versatility, strength, and durability make it an indispensable material in various mining applications, helping to enhance efficiency, productivity, and safety in mining operations.

- Q:Can steel wire mesh be used for agricultural cages?

- Yes, steel wire mesh can be used for agricultural cages. It provides a sturdy and durable structure that can effectively contain and protect animals or plants in an agricultural setting.

- Q:Can steel wire mesh be used for architectural elements such as facades?

- Steel wire mesh is an excellent choice for architectural elements like facades. Its numerous advantages make it highly suitable for architectural applications. Firstly, it is highly durable and can withstand harsh weather conditions, making it perfect for outdoor use. Additionally, it is resistant to corrosion, ensuring that it will last a long time. Furthermore, its design flexibility allows architects to easily shape and mold it into various sizes and shapes, enabling them to create intricate and unique facades. Moreover, it provides transparency, allowing natural light to enter while still maintaining privacy. It can also be used to create captivating visual effects and patterns on the facade, enhancing the building's aesthetic value. In conclusion, steel wire mesh is a versatile and practical material that can be effectively used in architectural elements such as facades.

- Q:How is steel wire mesh used in reinforcement of slabs?

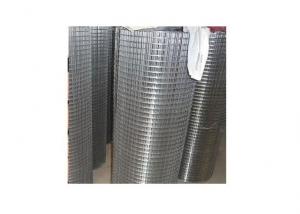

- Steel wire mesh is commonly used in the reinforcement of slabs to enhance their structural integrity and durability. The mesh is made up of interconnected steel wires arranged in a grid pattern, which provides additional strength to the concrete slab. To use steel wire mesh for slab reinforcement, it is typically placed in the middle of the concrete slab, slightly above the bottom layer. The mesh is positioned to provide uniform coverage throughout the slab's area, and it is held in place using support chairs or steel rebar. The primary purpose of steel wire mesh reinforcement is to control cracking and provide tensile strength to the concrete slab. As concrete is strong in compression but weak in tension, the mesh helps distribute the tensile forces evenly across the slab's surface, preventing cracks from forming and spreading. This reinforcement also improves the slab's resistance to bending and shear forces, making it more resistant to structural failure. In addition to enhancing the strength of the slab, steel wire mesh reinforcement also provides other benefits. It improves the overall durability of the slab by reducing the impact of temperature and shrinkage-related stresses. It also helps to minimize the effects of settling or shifting of the ground beneath the slab. Furthermore, steel wire mesh reinforcement can be used to reinforce thinner slabs, reducing the amount of concrete needed and saving on construction costs. It is also relatively easy to install, making it a practical choice for various construction projects. Overall, steel wire mesh is an essential component in the reinforcement of slabs as it significantly improves their strength, durability, and resistance to cracking. Whether used in residential, commercial, or industrial applications, this reinforcement method ensures that the concrete slab can withstand the loads and forces it will encounter over its lifespan.

- Q:What are the different mesh counts available for steel wire mesh?

- There are various mesh counts available for steel wire mesh, ranging from very fine to more open weaves. The mesh count refers to the number of openings or holes per linear inch in the mesh screen. The most common mesh counts for steel wire mesh are typically between 2 and 400. Mesh counts below 10 are considered coarse, while those above 200 are considered fine. Coarse mesh counts, such as 2 to 10, have larger openings and thicker wires, making them suitable for heavy-duty applications like mining screens or fencing. Medium mesh counts, ranging from 12 to 100, are commonly used in applications like filtration, separation, and reinforcement. These mesh counts strike a balance between strength and openness, providing durability while still allowing for adequate airflow or visibility. Fine mesh counts, from 120 to 400, are ideal for applications requiring precise filtration or separation. They have smaller openings and thinner wires, offering excellent particle retention capabilities. Fine steel wire mesh is often used in industries such as pharmaceuticals, food processing, and laboratory testing. It is important to note that the specific mesh counts available for steel wire mesh may vary depending on the manufacturer or supplier. Additionally, custom mesh counts can be made to suit specific project requirements.

- Q:Can steel wire mesh be used for bird feeders?

- Indeed, bird feeders can make use of steel wire mesh. Steel wire mesh, known for its durability and sturdiness, can withstand the harsh outdoor conditions, making it an excellent option for bird feeders. It offers a robust framework that securely holds the bird seeds, facilitating easy access for the birds. Moreover, the fine gaps in the mesh prevent larger birds or squirrels from reaching the food, ensuring that only the intended bird species can partake. Furthermore, steel wire mesh is effortless to clean and maintain, making it a highly practical choice for bird feeders.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Coated Chain Link Fence With Hot Dipped Galvanized Wire Inside

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products