PVC Ceiling Wall Panels for Cheap Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 2400000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. good resistance to climate change, and the geometry of the stability

2. light weight, tension strong, fire resistant, acoustical absorption, warm keeping, ametabolic

3. water-proof, smoke-proof, moisture-proof, mould-proof, fading-proof, heat-resistant and cold-

preventing, antistatic, no color difference

4. high intensity and strong tension, hard to twist under pressure

5. beautiful and unique designs, with coverage of any patterns you desire, being installed with keel(T-

bar) could get excellent decoration effect and makes life relaxed and delightful.

Product Applications:

Household Ornament: Wall and ceiling of indent independent house bathroom

Public and Management Place: Toilet of building and hall, bathroom and kitchen

Usual Packing: 10pcs/shrink wrapping or carton

Main market: South America, Eastern Europe, Southeast Asia, Eastern Asia, Africa, Oceania and Mid East.

Product Advantages:

1.resistance to humidity;

2.resistance to extreme temperatures;

3.it doesn't require any special maintenance being sufficient to wash it with water spray and a sponge;

4.doesn't get mouldy, doesn't rust or rot, doesn't require sanding and doesn't require painting or varnishing;

5.economy of money and time due to easy and quick mounting way;

6.they can be easily replaced in comparison with tiles or wallpapers;

7.doesn't support combustion;

8.minimum 30 years of life.

Main Product Features:

1 The Glossy printing ,smooth, without gap when concatenated

2 The variety of colors and patterns

3 High intensity, resist corrode ,long life time, simple to maintain

4 Healthy and good for environmental protection

5.We export our goods to the following area:

Middle-east, East Europe, Africa, Russia, South-eastern Asia,and so on.

Regarding the distribution type or exclusivity type, it depends on. We also do

the brand name for the customers' request only.

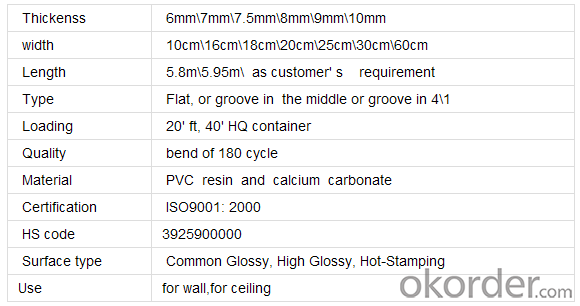

Product Specifications:

FAQ:

1.Terms of payment:

T/T or LC.

2.Delivery time:

within 10-15 days after receiving the 30% deposit.

3. Port of Loading:Shanghai

4.Price terms: FOB Shanghai

Images:

- Q:What is PVC material?

- Polyvinyl chloride. Basic features: It is one of the world's largest production of plastic products, cheap, widely used, polyvinyl chloride resin is white or light yellow powder. Depending on the application, different additives may be added, and the polyvinyl chloride plastic may exhibit different physical and mechanical properties. In the polyvinyl chloride resin by adding the right amount of plasticizer, can be made of a variety of hard, soft and transparent products. Pure polyvinyl chloride density of 1.4g / cm3, adding plasticizers and fillers such as the density of PVC plastic parts is generally 1.15-2.00g / cm3. Hard polyvinyl chloride has a better resistance to tensile, bending, compression and impact resistance, can be used alone as a structural material. Soft polyvinyl chloride softness, elongation at break, cold resistance will increase, but the brittleness, hardness, tensile strength will be reduced. Polyvinyl chloride has a better electrical insulation properties, can be used for low-frequency insulation material, its chemical stability is also good. As the thermal stability of polyvinyl chloride is poor, long-term heating will lead to decomposition, release HCL gas, so that PVC discoloration, so its narrow range of applications, the use of temperature is generally between -15 ~ 55 degrees. The main purpose: Because of the high chemical stability, it can be used to make anti-corrosion pipes, pipe fittings, oil pipelines, centrifugal pumps and blowers. Polyvinyl chloride board is widely used in the chemical industry to produce a variety of storage tank lining, building corrugated board, doors and windows structure, wall ornaments and other building materials. Because of electrical insulation performance, in the electrical, electronics industry, for the manufacture of plugs, sockets, switches and cables. In daily life, PVC used in the manufacture of sandals, raincoats, toys and artificial leather, etc.!

- Q:Pvc board how to install curved curtains

- Bending and straight rail installation is the same way, ah, to the time are straight, but according to the size of the scene is the current curvature of the bend, the installation code is similar.

- Q:Hibiscus board and PVC board commonly used and do what?

- Mainly the ceiling material , Furong board is a new type of chemical materials, polyethylene is the main raw material, sweet plus a variety of additives, the chemical bridge from the foam, single-sided composite PVC board.

- Q:PVC safety sign board 2mm thick, tolerance selection part of the mold activity is not affected by the mold or part of the impact of the activities of the class B it? Accuracy without requirements, 1.8mm thick can meet the standard? Please let the big god to explain. thank!

- GB / T 22789.1-2008 provides general purpose grade extruded sheet thickness (d) limit deviation = ± 13%. Ie 2 ± 0.26mm. Specified special purpose grade Extrusion sheet thickness (d) Limit deviation = ± (0.1 + 0.03d). That is 2 ± 0.16mm

- Q:Plastic buckle ceiling ceiling how much money a square meter

- Twenty or five, slightly different around, it is recommended to consult the local master.

- Q:Blister and PVC board distinction. Detailed description of the best.

- Blister board is an amorphous, odorless, non-toxic, highly transparent colorless or slightly yellow thermoplastic engineering plastics, with excellent physical and mechanical properties, especially excellent impact resistance, tensile strength, bending strength, compressive strength High; creep small, stable size. In fact, PVC can do plastic panels but do not have the effect of PMMA good At present the industry with acrylic plastic products to do more, but the price relative to the PVC to be high! Hope to help you

- Q:In the MDF posted a layer of PVC, is the plastic plate? But the plastic board is surrounded by the edge of the ah, who knows the name of this plate ah?

- Density fiberboard (HDF) is a kind of sheet made of wood fiber or other plant fiber as raw material, urea urea resin, or other synthetic resin under the conditions of heating and pressing. Smooth, in the ambient temperature and humidity changes, the size of good stability, easy to surface decoration treatment. The internal structure of fine, in particular, has a dense edge, can be processed into a variety of special-shaped edge, and do not have to cover the edge of the direct coating, you can achieve better shape effect. Uniform structure, inside and outside the same, so you can carry out the surface of the carved processing and processing into a variety of sections of the decorative lines, suitable for the replacement of natural wood for structural materials. Fiber density board is made of wood, branches and other objects in the water after soaking broken, made of wood fiber or other plant fiber as raw material, the application of urea-formaldehyde resin or other suitable adhesive made of man-made sheet. A particle made of wood or other lignocellulosic material, a wood - based panel that is glued under the action of heat and pressure. Also known as particle board. Mainly used in furniture and construction industry and trains, car manufacturing. Here mainly describes the fiber density board.

- Q:Pvc stamina board can drill their own?

- Yes, but before installation, it is recommended to re-drill, according to the recommendations provided by the manufacturers to install, the plate itself has the characteristics of thermal expansion and contraction, need to reserve space. Hope that the above answer can help you, thank you.

- Q:Pvc floor green? Can you pave it in the bedroom?

- Pvc floor is absolutely environmentally friendly. General pvc floor of the main raw material is PVC, is environmentally friendly non-toxic renewable resources, relative to the wood floor of formaldehyde and other harmful substances, pvc floor environmental performance has an absolute advantage. Pvc plastic flooring is the main raw material is polyethylene plastic, and the selection of non-radioactive marble powder. Polyethylene plastic is environmentally friendly non-toxic renewable resources, in the production process all added ingredients are completely non-toxic non-radioactive, does not contain any heavy metal its environmental protection is no need to worry, it is real, green green floor. At present, many people do not understand this floor,

- Q:Who has pvc foam board performance indicators ah?

- Applicable temperature: -50 degrees Celsius -70 degrees Celsius Heating temperature: 70 degrees Celsius -120 degrees Celsius (making profiles) Bending strength: 45.6mpa Low temperature: (-5 degrees Celsius down the impact) 10 times zero broken life: not less than 50 years Product testing methods: (1) board: smooth and smooth, mechanical texture is not obvious, the surface color without color, milky white, no stains on the surface, no obvious pits, no pinholes, no thick holes, cracks. Note: non-milky white foam plate into the recycling waste plate, does not belong to the environmental protection board, environmental protection board does not lead (content is less than Europe and the United States standard). (2) plate side: incision smooth, fine pores, no pinhole, no thick hole, out of powder is not serious, no honeycomb, open fiber from the fall off, do not jump mouth. Note: The above situation to be careful, and then order to do the finished product trouble. (3) thickness measurement: caliper stand surface, the contact seamless seamless, left and right thickness uniform, left and right measurement, the deviation is large, thickness deviation positive and negative 0.2MM as normal. (4) Plate weight algorithm: Weight (g) = L * W * Thickness (cm) * Density, (5) Density algorithm: Density = Weight (g) / L * W * H (cm).

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Ceiling Wall Panels for Cheap Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 2400000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords