PVC Ceiling & Wall Panel for Interior Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Description

PVC Ceiling for Interior Decoration

We are a professional PVC Ceiling panel manufacture since 1992, offering hundreds of patterns and colors of PVC panel with high quality and competitive price. And monthly output up to 480,000 Sqms.

Different types of PVC Panel we are producing:

1, Glossy PVC Panel (most common type)

2, Sub-glossy PVC Panel (Natural surface handing)

3, High-glossy PVC Panel (high-light surface handling)

4, Transfer Printing PVC Panel

The hottest specifications of PVC panels on the market:

Length: 3m-6m as request.

Width: 200mm/250mm/300mm/600mm

Thickness: 4mm/4.5mm/6mm/7.5mm/8mm/9mm/11mm

PVC percentage: 35%-75%

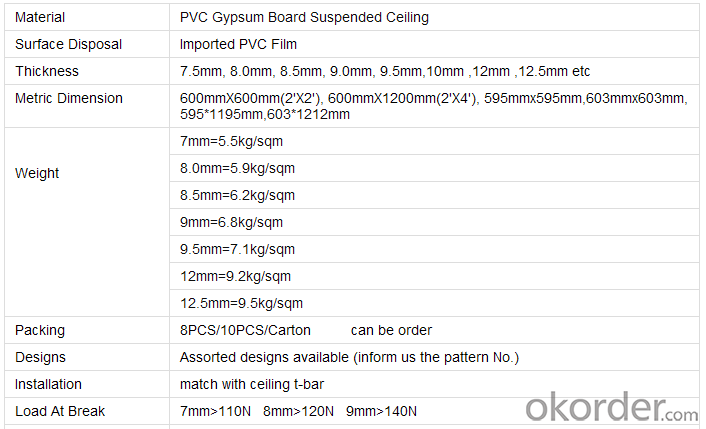

Specification:

1) Easily installation,surface is smoothness,flatness,without gap when concatenated.

2) High intensity,good quality,not easy to deformation,resist erosion,mothproof,sound insulation,waterproof,fireproof,aging-resisting,durable.

3) It can be processed by drilling,sawing,nailing.Hot bending,hot-folded.

4) Interior decoration for ceiling,wall.Easy cleaning,healthy and environmental.

3.Image

4.Detailed Specification

5.FAQ

Application

The panels are designed for covering internal walls or ceilings in any room in the home or commercial space, but they are specifically conceived for wet environments such as bathrooms, showers, kitchens or utility rooms.

Feature:

1) Easily installation, surface is smoothness, flatness, without gap when concatenated.

2) It can be processed by drilling, sawing, nailing.

3) High intensity, high strength, not easy to deformation, resist erosion, sound insulation, waterproof, fireproof, aging-resisting, durable.

PVC Panel Production Process:

A) Main Raw Material: PVC Resin and Calcium Carbonate, More PVC Resin better quality.

B) Step 1: Mixing Machine mixes the PVC Resin, Calcium Carbonate and others material thoroughly.

Step 2: Molding machine heat the raw material to make it as whole PVC by 230degree temperature.

Step 3: The mold pile out the PVC, and then change it as semi-manufactured PVC panel goods.

Step 4: Put the semi-manufactured PVC panel on the printing machine to print design and color and PVC resin oil on the PVC panel.

About us:

1. Has a certain degree of the scale and efficiency till now

2. Advanced printing machines

3. Twenty lines work together

4. Treat every order with responsibility

5. Rich experience in export to countries from Middle East, South Africa, Southeast Asia, South America and so on.

- Q:Pvc board ceiling how much manual

- Now about 40 yuan per square meter.

- Q:Ring thickness of 5-10mm, diameter 250mm, diameter 150mm, PVC board raw material is 1 meter by 2 meters. Products to mass production, would like to ask what kind of equipment can be directly on the shelf 1 meter by 2 meters on the plate to cut products? I find someone else manufacturers out of a sample, but I do not know what they are using the machine, only know that carved machine.

- Computer engraving machine with program control.

- Q:Hollow engraved high density board and PVC which is good

- Hollow carved flowers

- Q:How to bend the pvc board into the desired shape, that is, a plexiglass-like plate. To process the DIY accessories. I want to bend it into the desired curvature or drum shape. How to get. Or burning it, it will turn black. Ugly. Do you use a hair dryer or do you use other methods? Hot water is really useful. Is there any other way? Do not work with a microwave oven?

- Small area with a small hair dryer or hot water on the line, it is best to do a mold, pouring hot water pressure and then pour cold water can quickly shape

- Q:just put a plastic ceiling up and my labourer put a dent in the 2nd board there are 9 pvc cladding boards on the ceiling but I cannot start taking them back out from the end to replace it as I have put a walk in shower in and the wet wall shower boards tie them in is there any other way I can replace it I havnt tiled it in yet the boards are silicone and screwed on the lip HELP PLEASEEEEEEEEEE!!! Thanks

- Without inspecting the installation, it would be hard to say. However, some general pointers. Possibly you can remove the ceiling boards from the other side. Consider carefully cutting away the dented portion of the panel. You can probably cut away the entire damaged panel and squeeze in a replacement. You can offer the customer a 50% discount on the job.

- Q:Wood-plastic board, PVC board, science and technology What is the difference between wood?

- Wood-plastic board is made of wood fiber mixed polymer plastic after extrusion molding, is an environmentally friendly material, its weather resistance is very good, generally used for outdoor decoration. Pvc board is made of pvc material of a material, it is light weight, have a certain strength, but the weather resistance of acid and alkali difference for product packaging and interior decoration. Science and technology wood is made of artificial veneer made of decorative panels, generally with no color, pattern and other natural decorative panels can not achieve the decorative effect, but its pattern rigid, color frivolous no less than the natural decorative panel texture and decorative grade.

- Q:Pvc board do cabinet how exactly? Urgent demand

- Well, beautiful decorative effect is good, durable and solid ah, but also cheap, alternative wood products

- Q:Pvc stone floor with hot water bubbles after the UV layer can be torn from the floor, and then you can smell the irritating smell, the business that no formaldehyde, but I think this taste UV layer is certainly sticking up and not hot The

- No. Pvc floor from the structure of the main multi-layer composite and homogeneous through-heart and semi-homogeneous body type 3. The so-called multi-layer composite PVC floor is that it is a multi-layer structure, generally from 4 to 5 layers of laminated structure, generally wear-resistant layer (including UV treatment), printing film, glass fiber layer, Foam layer, grass-roots level. UV treatment is the use of epoxy resin for surface reinforcement in a way that can play anti-pollution and effective absorption of ultraviolet light, enhance wear resistance, delay product aging and easy to clean the role.

- Q:PVC floor discoloration how to deal with?

- If you do, add titanium dioxide. Rutile type If the purchase has been posted up the words. You can see the floor sales shop for a long time. The normal use of this phenomenon is a quality problem

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Ceiling & Wall Panel for Interior Decoration

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords