PVC Ceiling Newly Design Competitive pice

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 550000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

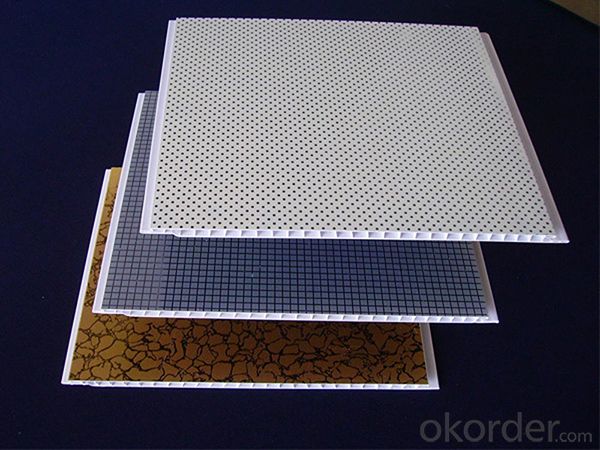

PVC Ceiling Newly Design Competitive pice

Main material:

PVC (50%, 60%, 70%, 85% or as your request), Caleium Carbon and other chemicals

Usual

specification

Length: customized size, such as 2.95m, 3m, 3.8m, 5.6m, 5.8m, 5.95m

Width: 5cm to 40cm or customized

Thickness: 5mm to 10mm or customized

Surface treatment

Oil print, hot stamping foil, thermal transfer print, laminated and so on as your pattern and color

Surface effect Bright/glossy, high glossy, matt, gleam, roller coating and so on

Production quality

Light of weight, powerful strength, high intensity, heat insulation, flame resistant, corrode resistant, age resistant, no aspiration, easy cleaning, easy installing and so on

Producing scale

With more than 60 PVC production lines and 100 kinds of moulds

Certificate

ISO9001:2000, Soncap, Intertek certificate

Application

Hotels, commerical buildings, hospital, schools, home kitchen, bathroom, indoor decoration and so on

Sample Free with International Express Delivery

FAQ

1. Is OEM available?

Re: Yes, OEM service is available.

2. Are you factory?

Re: Yes. we are the largest factory in China.

3. Can we get sample?

Re: Yes, sample is free for our customer.

4. How many days for production

Re: usually 2 weeks after receiving of downpayment

Pictures

- Q:PVC foam board on the market now uneven quality, is said to have a true crust and false crust, but do not know how to distinguish, and asked, Baotian Hi-Tech production of PVC crust foam board quality? Please tell you please.

- The true crust is made with a stoppage method, which forms a layer of dense hard crust on both sides of the sheet, which can improve the hardness and nail force of the plate. These physical properties are very important for the manufacture of furniture or for the decoration of the house. To identify the PVC board is (really) crust, in fact, very simple! As long as the shop does not pay attention to the thumb with the nail on the PVC board pressure, and then carefully check whether there is a deep dent, if there is, is clearly false, it is best not to. Celuka (Celuka) also known as controlled foam method, the current application is very wide, by the French gine kulmann company invented, it is the first patented one of the extrusion foam molding method. The principle of the Luca method is that the outer skin of the melt is compressed and cooled in the styling device directly connected to the die, and the mandrel in the cavity ensures that there is room left when the extrudate leaves the die Through the melt in the mold within the free foam is filled. Cooling strength, core mold size, extrusion speed, can affect the foam core layer density and outer crust thickness. The complex shapes of the profiles produced in this way have the characteristics of low density, high hardness and smooth surface. Baotian Hi-Tech can visit, in addition to their production of PVC crust foam board, but also the production of PVC own foam board, PVC foam profiles, product quality belongs to the high-end

- Q:Pp board and pvc board 20mm thick now how much money a square?

- Production of PVC external wall hanging plate with anti-aging, anti-radiation, anti-corrosion, fire-retardant, handsome in appearance, easy to install features for all types of buildings indoor and outdoor walls, shed decoration, is a new Green materials. The newly developed hot-dip galvanized electrostatic spray guardrail has the characteristics of simple installation, high strength, no pollution, corrosion resistance, maintenance-free, self-cleaning and so on. It is suitable for industrial and mining enterprises, institutions, municipalities, roads, parks, Schools and other places

- Q:Hibiscus board and PVC board commonly used and do what?

- Product characteristics Anti-aging, anti-ultraviolet radiation; oil, acid, alkali and other organic chemical composition corrosion; sound-absorbing, noise, thermal insulation; light texture, easy to store, anti-aging, anti-aging, anti-aging Transport, processing, cutting, carving and so on

- Q:PVC board acid resistance?

- Hydrochloric acid concentration of 32%, the temperature of 50 degrees below the PVC board. no problem Temperature over 50 degrees with CPVC board, the cost of low available PP board, but the hardness and CPVC are different.

- Q:Production of PVC foam board of raw materials are what ah? What is the role of ah?

- PVC resin: This is the most important raw materials, foam substrate, the production of PVC foam sheet generally use P-700-type PVC resin, the processing of its gelation speed, processing temperature is relatively low, product quality and density Easy to control. In the production of leather foam PVC sheet, in order to improve product quality, strict control of product density and thickness fluctuations, more use of P-700-type vinyl PVC resin. In the production of free foam PVC sheet, from the lower production costs to consider, there are many manufacturers using calcium carbide P-700-type PVC resin

- Q:PVC crust foam surface can brush latex paint?

- Water-based latex paint on the PVC foam board no adhesion, if you do not ask strict, a small area of the best spray paint, the PVC foam board grinding and then spray will be better, if it is to do the list of orders such as display panels, PVC Bathroom cabinet painting, the best use of special paint. My company is doing this PVC foam board paint, excellent adhesion, good water resistance, will not fall off the bubble.

- Q:PVC bathroom cabinet is good

- Pvc bathroom cabinet advantages and disadvantages Advantages: pvc waterproof, light weight, good stability, practical life is relatively long, and cheap. Disadvantages: pvc some of the toxic additives and plasticizers, may exudate or gasification, causing a certain harm to human health, environmental protection is poor.

- Q:You decorate people ~ PVC board to do the whole living room bedroom wall and how the top?

- not so good. Monotonous rigid grade is not enough I hope my solution will help you

- Q:What is the temperature of the production PVC board?

- PVC board is divided into hard board and soft board, the general hard PVC melting temperature of 120 degrees, soft PVC melting temperature of 115 degrees.

- Q:Acrylic PVC organic board What is the difference between these three materials What is the difference

- Acrylic chemical name: PMMA good light transmission, the board is more brittle, blister forming effect is good, mainly for light box plate Organic chemical name: PS good light, the board is more brittle, plastic molding rate without high acrylic, mainly for light box plate PVC material performance unfamiliar

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Ceiling Newly Design Competitive pice

- Loading Port:

- Ningbo

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 550000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords