PVC Ceiling Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 Square Meters m²

- Supply Capability:

- 100000 Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description of Pvc Ceiling Board

we are a professional manufacturer of pvc ceiling panel.pvc decorative wall panel.pvc sheet.pvc ceiling tiles.

Pvc Ceiling Board Specification:

1) Width: 20cm, 25cm, 30cm, 60cm or or as per customers'requirements

2) Thickness: 4.5mm,5mm,6mm,7mm,7.5mm,8mm,8.5mm,9mm,9.5mm,10mm,12mm or as per customers'requirements

3) Length: 2m, 2.7m, 3m, 4m, 5.8m, or 5.95m, or as per customers'requirements

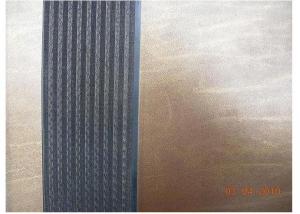

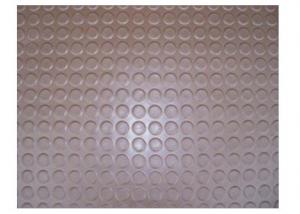

4) Color: marble, wooden, and other more than 200 article designs.

5) Pattern: Modern design

6) Surface Treatment: Printing, transfer printing, high glossy, laminated,

7) Packing: Shrink-film, usually 10PCS/bundle or according to per customers' requirements

Feature Of Pvc Ceiling Board

1) Easily assembly, surface even, without gap when install

Widely used in bathroom, kitchen, house room, drawing room, hotel, school and hospital and other business buildings.

2) High intensity, corrode-resisting, aging-resisting, can be used more than 30 years

3) Prevent fire, antibiotic, healthy and environmental

4) The surface picture is clear and adhesive

5) For Ceiling and Wall decoration...

6) More than 200 specifications, 300 article pictures...

- Q:How long is a fire extinguisher still usable? How do you safely dispose of an old one?

- Kewl, I'm kind of the same way only instead of hurling lightning it's usually a lamp or my dog

- Q:Spiritually speaking, doesn't a lightning rod on top of a church show a lack of faith?

- Wash with Cetaphil for oily skin (not the bar) 2 times a day After washing, use Dickinson's Witch Hazel 100% natural (walgreens, cvs) Then, use Aloe Vera Gel Moisturizer by Fruit of the Earth.morning and night. And, for extra measure use De Slick by Urban Decay Exfoliate a few times a week (I use Apricot Scrub by St Ives and Jan Marini's Bioglycolic Cleanser) Drink lot's of water.

- Q:I have had bad luck with 2 part casting resins , is there an easy-to-use product on the market?

- Necessary: -kool-stop salmon brake pads - BRIGHT lights - rainpants, Frogtoggs are cheap and good - rubber knee-high boots - glittens - goggles - balaclava - practice fishtailing (skidding) on mud and wet grass, very different from clear pavement. -bus pass Helpful: - classic drop handlebars as the wind feels at least three times as dense in winter and availability of an aero-position is a cheap luxury - lower the saddle .5 - 1 inches for more wiggle room navigating chunks of car-poop and newly formed potholes - fenders - dual fixed hub w/ 4 tooth difference between cogs and a short chain extension with 2nd master link, choose a chainring to go with a ~14t cog for non-snow riding and then have a 18 or bigger cog for when you get the inevitable heavy wet snowstorm. Not necessary: - knobby tires (they help in dirt but seriously do almost nothing in snow) - being a badass and trying to ride when ice is forecasted I have a second bike that I built up for dealing with the ice with studded tires. I've put it to good use nine times in the last four years. I'm turning it back into a trail bike and leaving it that way. When the ice is bad enough that you need studs, it is also bad enough that you don't want to share the road at all with the cars. I do keep a pack of stainless steel guitar strings in my toolkit along with a few scraps of cloth (to protect the rim) just in case after working the night shift the formerly clear roads have turned into oily glass.

- Q:this is my first time to handle any plumbing. i want to install a hand shower (hand bidet) beside the toilet.Guys at Lowe's helped me with a Watts 3 way 3/8 adapt-a-vavle and a piece of 3/8 soft copper tubing to connect the outlet on the adapt-a-valve to the 3/8 intake on the hand shower.Problem is i don't know how attach copper tubing to both sides.the tube fits inside both fittingsbut it's loose.should they have given me some tubing with a flar ? any ideas ??

- There are rubber casters you get get in the hardware section of the Home Depot. The rubber ones will be best since you will need the friction to stop from movinghopes this helps.

- Q:I want to do the experiment but im worrying about the threats may encounter.

- Either they don't like the feeling of going over the bump or they don't want to risk damaging their cars.

- Q:ok so the ice is melting, and with technology today scientists know how much new water will be added into the ocean, and they have a rough estimate of when the ice will all be gone. at the same rate why dont they take giant containers filled with ocean water each year, matching the amount of new water from the melting ice. these containers could be stored anywhere, and could even serve as backup water supplys for times of drought, or in times of disaster like hurricane katrina.

- Doesn't your religion have a rule against bearing false witness against thy neighbor ???? Home depot said no such thing about the wrong God or Allah.They gave him a free pass on the rules for one year (which was their first mistake, they should enforce the dress code across the board and consistently), and now he is having a hissy fit, because he is no longer getting a free pass on the dress code. If you really think that what REALLY happened is so terrible, why do you have to embellish the story with FALSEHOODS ????

- Q:i need to know what a reflective essay is, please it's very important i need one of those for my SSE class. please explain how many paragraphs, what to say in those or just an example of a reflective essay to see how it looks like so i can see what to include or not. I really appreciate that and thank u for answering my Qs. :)

- well, the way i look at it is 'live and let live'; my dd always wears swaddlersdoes that make me a snob? well, that's all she can wear that works..as for strollers, yep, i splurged on a maclaren umbrella stroller and i am glad i did, it's great! if i couldn't afford it, i wouldn't have bought it, and i didn't buy it bc of the name, ibought it simply bc i liked it and it's features..same with everything else; if i like it i will buy it, if it is a huge brand name or not; if i don't, i don't care what brand it is, i am not buying itjust like maclaren has a black leather baby strollerhow crazy is that? it was a 1000, but now like 800, but i wouldn't pay ten bucks for it bc i think that would be uncomfy for my baby..sucks, but a lot of the time, u get what you pay for.and i don't mean to come off as snooty, but for instance, i got my dd one of those push along toys, it sucked. so i went back and found another brand that was ten or fifteen more dollars than the first, but it is great and she loves it!

- Q:What are the internal structures of sand blasting room?

- Sand blasting room wear-resisting plywood: the choice of wear-resistant plywood, after years of experience in the use of white rubber panels, produced by professional manufacturers, professional packaging. The white rubber plate has good light reflection and greatly increases the brightness of indoor lighting, and is more wearable.

- Q:I'm building an HHO torch, meaning that the gas I'll be using for welding is Hydrogen. I've heard (but I don't know for sure) that Hydrogen burns at 4000 degrees Fahrenheit. What kind of goggles would give sufficient protection for my eyes for welding. I'll be welding all types of metal: Stainless steel, copper lots of stuff. Let me know what would work best.Thanks!

- The best product to use is felt pads. They are small round pads made of compressed fibre (either with adhesive or nails) to be fitted under each chair or table leg or distributed evenly along the bottom of furniture. They are usually available in large hardware stores like Home Depot. You can also use rubber pads for example 3M Bump-ons In the worst case you cannot find these you can make your own, cutting squares out of reasonably hard synthetic rubber sheet at least 10mm thick and glue with araldite!

- Q:it seems like they are setting up for this 6 man match.BQ - Should Undertaker vs CM Punk be Hell in a Cell? BQ2 - Should CM Punk vs Taker be the last match?

- If your rubber gasket is still 'live' rubber (still pliable and soft) you should not need any other sealant. Otherwise you would do well with a silicone-100 percent silicone rubber, It will work but, you need to give it a few hours to set up and overnight to dry completely. Do the work before you got to bed and no longer use to sink.

1. Manufacturer Overview |

|

|---|---|

| Location | Zhejiang,China (Mainland) |

| Year Established | 2009 |

| Annual Output Value | US$5 Million - US$10 Million |

| Main Markets | South America Southeast Asia Mid East Eastern Asia South Asia |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 11% - 20% |

| No.of Employees in Trade Department | 1-2 People |

| Language Spoken: | English, Chinese |

| b)Factory Information | |

| Factory Size: | 5,000-10,000 square meters |

| No. of Production Lines | 5 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | Low and/or Average |

Send your message to us

PVC Ceiling Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 Square Meters m²

- Supply Capability:

- 100000 Square Meters per Month m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords