PVC Ceiling And Wall Cladding PVC Tiles for Ceiling

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

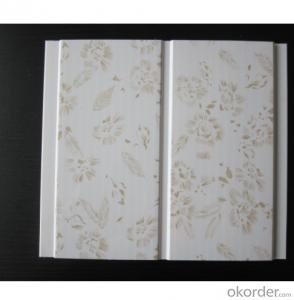

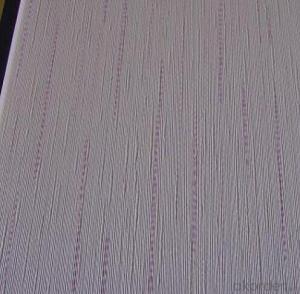

PVC ceiling and wall cladding

1. Size: 7mm X 25cm

2. Elegant ceiling effect

3. Max length is 5.95m for loading&install

Product Applications:

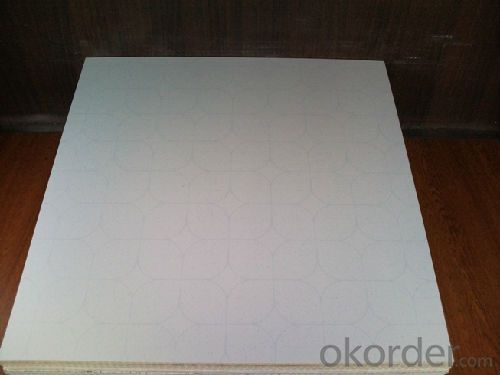

Ceiling Tile Sharp:Rectangle

Ceiling Tile Type:PVC Ceiling

Width:200mm

Surface treatment:printed

PVC content:40% or 50%

Thickness:6.8-12mm

Color and design:Hundreds of designs for your ...

Package:PVC shrink-film or PE-flim

Product Advantages:

Other companies claim their tiles/panels are washable (only temporarily) and some even claim to be waterproof, but only our tiles can be washed over and over, even a million times, and never be damaged. They are completely waterproof, will never grow mold and will never sag, bow, or bend due to humidity. They have a Class A flame spread and smoke developed index that's approved for all commercial kitchens and dining areas and can be used in any standard grid for drop ceilings. They are very decorative (not industrial looking) and are perfect for not only kitchens but offices, warehouses, food processing plants, clean rooms, bottling plants, and gymnasiums. Too numerous to name them all, so basically anywhere there is a drop ceiling our tiles will work great.

Main Product Features:

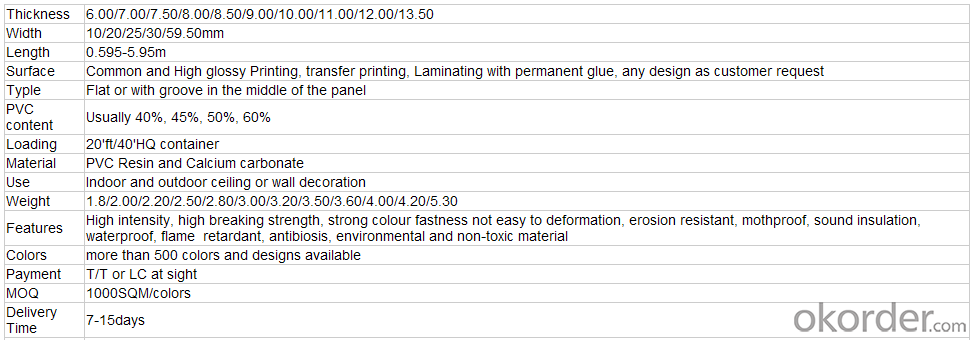

Thickness: 5mm, 7mm, 7.5mm, 8mm, 9mm or by request

Width: 10cm, 18cm, 20cm, 22cm, 24cm, 25cm, 38cm or by request

Length: Regular 5.95m, also as per your requirements.

pvc ceiling panels Features: Fireproof, waterproof, anti-warm and environment friendly,

For Ceiling and Wall decoration

Product Specifications:

Images:

- Q:Pvc how to heat the deformation of soft board, to make their own shape

- Small on the hair dryer, the factory on the infrared or oven heating

- Q:Will pvc floor is how to make out, it is best to specific? Thank you!

- There are many, soft heart. Soft multi-layer lamination. Hard wood plastic, foam and so on

- Q:What is the difference between pvc flooring and plastic flooring? Is there a stone floor?

- Of course there is a difference! Stone floor is a sheet, plastic floor is a coil, OKorder and OKorder plastic flooring factory has a coil dance plastic floor dance dedicated! Sports plastic floor badminton court dedicated, table tennis field dedicated, gym dedicated, basketball court dedicated! OKorder plastic floor PVC flooring is a very popular in the world of a new type of lightweight ground decoration materials, the advantages of many, also known as "light body material." Is a popular in Japan and the United States and Japan, Japan and South Korea popular products, popular in foreign countries, from the early 80s began to enter the Chinese market in the country's large and medium-sized cities have been widely recognized, the use of a very wide range, such as indoor families, hospitals, Schools, office buildings, factories, public places, supermarkets, commercial, sports venues and other places. "PVC floor" refers to the use of PVC material produced by the floor. Specifically, polyvinyl chloride and its copolymer resin as the main raw material, adding filler, plasticizer, stabilizer, coloring agent and other accessories, in the continuous sheet on the substrate, the coating process or by rolling, extrusion or extrusion Craft production.

- Q:Whether the pvc board is poisonous

- Pvc sheet is mainly plastic material, case of heat easily deformed at the same time the distribution of gas Certainly some of the home decoration do not use PVC, kitchen and toilet area is not great, with more than one hundred points hanging plate hanging good, PVC for a long time will be yellow, buckle plate thickness of the best in more than 0.6mm, Buy the time to pay attention to the next package, the installation of PVC, but also to install people. Also buy wood to fight trouble.

- Q:How to clean the kitchen ceiling pvc board What cleaning?

- Like to avoid the use of wood keel, and PVC board after a period of time easy to change color, aging or damage, sticky oil is difficult to clean. Therefore, the current open kitchen ceiling decoration generally use waterproof plaster board, aluminum plate, moisture board.

- Q:Bathroom cabinet pvc plate is solid wood particles board it

- General performance PVC resin is a white or light yellow powder, the relative density of 1.35-1.45. The soft and hard degree of the product can be adjusted by adding a plasticizer. The following are the same as the " Mechanical properties PVC has a high hardness and mechanical properties. And increased with the increase of molecular weight, but with the temperature rise. Hard PVC mechanical properties, and its elastic modulus up to 1500-3000MPa. While the soft PVC elasticity of 1.5-15 MPa. But the elongation at break up to 200% -450%. PVC friction in general, static friction factor of 0.4-0.5, dynamic friction factor of 0.23. The following are the same as the " Thermal properties of PVC heat stability is very poor, 140 ℃ began to break down, the melting temperature of 160 ℃. PVC linear expansion coefficient is small, with flame retardant, oxidation index of up to 45 or more. So in the processing process need to add heat stabilizer, to ensure product performance. The following are the same as the " Electrical properties PVC is a good electrical properties of the polymer, but because of its large polarity, electrical insulation than PP and PE. Dielectric constant, dielectric loss tangent and volume resistivity, resistance to corona is not good, generally suitable for low pressure and low frequency insulation materials. The following are the same as the " Environmental performance PVC can withstand most of the inorganic acid, alkali, salt, most organic solvents. Suitable for medicine, chemical anti-corrosion materials.

- Q:Do blister light with 5 mm PVC board when the bottom plate, no knife cut there is no good way to quickly repair the bottom

- Cut with a cutting machine just fine, as long as the file to do a good floor can also be engraved with engraving machine

- Q:On the PVC plastic plate pressure groove

- It is very simple, you want to weld is not a hot air gun? First punch, and then the front and back bake soft, pay attention to the distance away, do not bake coke, crack, bubble, to be a corresponding size of the lumps (male) and bowl-shaped plate (female), and then baked a good plate Put on a good position, with the Yang model hammer or stamping is not enough

- Q:Outside are haze, home to be environmentally friendly, it is best sterilization, who knows who knows this is the case

- 1. Home pvc floor is usually pvc sheet flooring, the thickness of the board in the 2.0mm to 5.0mm, usually in the case of household 3.0mm to 5.0mm can be, the thicker the better. 2. Construction conditions are: flatness (within less than 2 meters gap is less than 2mm), humidity (less than 3.5), temperature (higher than 18 degrees). The ground of the hairy house is usually cement, the domestic cement ground cut corners too much, usually do self-leveling cement (that is, "leveling"), not much money. 3. Small holes are cemented vent holes, too much water lead. And then make the following self-leveling cement. 4. Home pvc floor, useful glue, there is no glue. Do not glue the home pvc floor moving at any time can be removed very convenient, that is more expensive unit.

- Q:Is the test board with high temperature?

- To a certain extent

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PVC Ceiling And Wall Cladding PVC Tiles for Ceiling

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords