PV Solar Panel 285w with TUV

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 600MW Annual Year watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Prices for pv Solar Panels (285W Solar Module) with 285W Solar Panel Certification TUV

Mono 285w Panel Certificated with TUV,IEC,CEC,CE and so on.

Solar Panel Mechanical Characteristics

Cell Type | Mono Crystalline 156×156mm(6 inch) |

No. of Cells | 72(6×12) |

Dimension | 1956×992×50mm |

Weight | 23kg |

Solar Panel Specifications

Module Type | NBJ-285M | ||||

Maximum Power at STC (Pmax) | 285Wp | ||||

Maximum Power Voltage (Vmp) | 36.25V | ||||

Maximum Power Current (Imp) | 7.87A | ||||

Open-circuit Voltage (Voc) | 43.4V | ||||

Short-circuit Current (Isc) | 8.41A | ||||

Module Efficiency (%) | 14.7% | ||||

Operating Temperature( °C ) | -40°C ~+90°C | ||||

Maximum System Voltage(V) | DC 1000V(TUV) / DC600V(UL) | ||||

Maximum Rated Current Series(A) | 15A | ||||

Power Tolerance | 0~+3% | ||||

Temperature Coefficients of Pmax | (-0.45±0.05)%/°C | ||||

Temperature Coefficients of Voc | (0.05±0.01) %/°C | ||||

Temperature Coefficients of Isc | (-0.35±0.02)%/°C | ||||

NOTC(°C ) | (47±2)°C | ||||

STC: Irradiance 1000W/M2 Module Temperature: 25°C AM=1.5

Quality and Safety

1. Rigorous quality control meets the highest international standards.

2. High-transmissivity low-iron tempered glass, strong aluminium frame.

3. Using UV-resistant silicon.

4. IS09001/14001/CE/TUV/UL

Solar Panel Warranty

Warranty | 10-year warranty on product material and processing technology |

Industry power output warranty: 90% in 12 years, 80% in 25 years |

Solar Panel Packing Configuration

Q’ty/Pallet, | 1×20’ft | 1×40’GP | 1×40’HQ |

Pallet Q’ty | 10pallets | 24pallets | 24pallets |

Q’ty/Container | 200pcs | 480pcs | 528pcs |

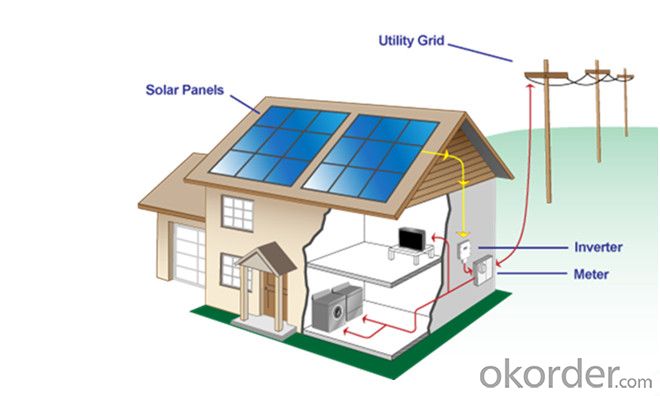

How the Solar Panel Works

FAQ

I..Will you focus on the safety of the goods during transportation?

Yes, Safety of the cargo is the primary element that we would consider on transportation.

II..How would guarantee the quality will meet the requirements of your clients?

Before shipment, we will have inspection for each batch of goods.

III..What certificates do you have?

IEC,UL,TUV,CSA,etc.

IV..Can you do OEM according to clients’ requirements?

Yes, we have our own brand while we can provide OEM service.

- Q:Can solar panels be installed on a hotel or hospitality establishment?

- Yes, solar panels can be installed on a hotel or hospitality establishment. In fact, many hotels and hospitality establishments are increasingly adopting solar energy to reduce their carbon footprint, lower energy costs, and showcase their commitment to sustainability. Solar panels can be installed on rooftops, parking lots, or even as shading structures, providing clean and renewable energy to power the establishment's operations.

- Q:Can solar panels be used in areas with high humidity or saltwater exposure?

- Yes, solar panels can be used in areas with high humidity or saltwater exposure. However, it is important to choose solar panels specifically designed for such environments, as they need to be corrosion-resistant and have proper sealing to prevent any damage from moisture or saltwater.

- Q:Can solar panels be installed on a barn or shed?

- Yes, solar panels can be installed on a barn or shed. In fact, barns and sheds are often ideal locations for solar panel installations due to their large, open rooftops that receive ample sunlight. Installing solar panels on a barn or shed can help generate clean and renewable energy while utilizing otherwise unused space.

- Q:Can solar panels be installed on a boat?

- Yes, solar panels can be installed on a boat. In fact, it is a popular and efficient way to generate electricity for various onboard systems, such as lighting, navigation, and charging batteries. Solar panels are lightweight, durable, and can be easily mounted on the deck or roof of a boat to harness solar energy and contribute to a more sustainable boating experience.

- Q:Can solar panels be installed on concert venues or music festivals?

- Yes, solar panels can be installed on concert venues or music festivals. In fact, many venues and festivals are increasingly adopting solar power as a sustainable and renewable energy source. Solar panels can be installed on roofs, canopies, or even on the ground surrounding the venue, providing clean energy to power the event and reduce its carbon footprint.

- Q:Can solar panels be used to power a greenhouse?

- Yes, solar panels can be used to power a greenhouse. Solar panels are a sustainable and efficient energy source that can generate electricity to operate various greenhouse systems, such as lighting, heating, ventilation, and irrigation. By harnessing the sun's energy, solar panels provide a clean and renewable power supply, reducing greenhouse gas emissions and minimizing reliance on conventional energy sources.

- Q:Also, what's the solar panel's rate of producing electricity?

- I'm okorder /

- Q:Can solar panels be used for satellite communication?

- Yes, solar panels can be used for satellite communication. Solar panels are commonly used to provide power to satellites, including the communication systems on board. The panels convert sunlight into electricity, which is then used to operate the satellite's communication equipment and other systems.

- Q:Can solar panels be installed on tile roofs?

- Yes, solar panels can be installed on tile roofs. However, the installation process may require additional precautions and expertise to ensure the integrity of the roof.

- Q:I just connected my 5 Watt 2V solar panel directly to my 300 Watt 2 inverter. It worked for about 2 minutes then it popped (sparks, smoke etc)! What the hell did I do wrong? I thought the solar panel was 2 volts? Can someone with experience with these things help me out?

- An 300W inverter will draw 25 amps from a car battery but the solar panel will only produce about 4 amps. By drawing too much power with the inverter you lowered the voltage so much in the panels wiring that the amp rating on the internal wiring was exceeded and they melted. Next, time run the panel to a voltage regulator, then the regulator to a car battery, then the battery to the inverter.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PV Solar Panel 285w with TUV

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 600MW Annual Year watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords