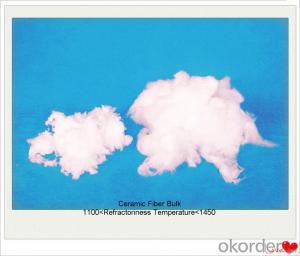

Pure White Thermal Insulation Blown Ceramic Fiber Bulk

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The ceramic fiber are manufactured from high purity raw material alumina powder ,silica sand for the high temperature grades and zircon sand is also used. The ceramic mixture is heated in an high temperature electric furnace and the stream of molten material is drawn into fibers by either spinning or blowing .It is produced by advanced “blown” and “spun” processes .Ceramic fiber bulk shows a high temperature stability ,low weight and heat capacity and an outstanding sound absorption is complemented by their resistance to oxidation and reduction

Excellent thermal and chemical stability

Low thermal conductivity and heat storage

Excellent thermal shock resistance and sound –absorption capability

No bonding agent and corrosive substance

Asbestos free

Technical data

Type | COM | STD | HP | HA | HZ |

Classification temp(ºC) | 1100 (2012℉) | 1260 (2300℉) | 1260 (2300℉) | 1360 (2480℉) | 1430 (2606℉) |

Work temp(ºC) | <1000 (1832℉) | 1050 (1922℉) | 1100 (2012℉) | 1200 (2192℉) | 1350 (2462℉) |

Color | Pure White | Pure White | Pure White | Pure White | Pure White |

Fiber diameter(um)Blown | 2--3 | 2--3 | 2--3 | 2--3 | 2--3 |

Fiber diameter(um)Spun | 3—4.5 | 3—4.5 | 3—4.5 | 3—4.0 | 3—4.0 |

AL2O3(%) | 44 | 45--46 | 47--49 | 52--55 | 39--40 |

AL2O3+SIO2(%) | 96 | 97 | 99 | 99 | ------- |

ZrO2(%) | -------- | -------- | -------- | -------- | 15--17 |

Fe2O3(%) | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 |

Na2O+K2O(%) | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 |

Application of Ceramic Fiber Bulk

Textile manufacture

Chimney fill

Expansion joint packing

Wet process feedstock

Filtration media

Kiln car infill

Ladle insulation

FAQ

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What other products does OKorder offer?

A3: We offer a full range of refractory bricks, monolithic material, ceramic fiber products, and more.

Q4: If I need your offer, what information do you need?

A4: In order to choose suitable products, it will be appreciated to provide us the information, such us specification, technical data, order quantity, products application etc.

If any question, please contact us freely.

- Q:Is aluminum silicate fiber poisonous?

- Hello, silicate in the stomach and stomach acid reaction, forming insoluble silicic acid. There should be no toxicity.

- Q:Aluminum silicate ceramic fiber cotton smoke will cause pneumoconiosis?

- 1, general masks, gauze, masks, etc., can not be used as dust masks.2, mask must pass GB 2626-2006 standard certification.3, it is recommended to choose N100 class dust masks.4, individual suggestions according to choose different shapes masks.5, it is recommended to change the filter gauze mask. Material recommended for silicone material.Through the above way, it can effectively prevent pneumoconiosis.

- Q:Glass fiber cotton, aluminum silicate cotton, rock wool, what's the difference between these three?

- Three kinds of materials are heat insulation materials, applications and temperature resistance is different.Glass fiber cotton is a kind of excellent performance of inorganic non-metallic materials, variety, has the advantages of good insulation, strong heat resistance, good corrosion resistance, high mechanical strength, but the disadvantage is brittle, poor wear resistance, the maximum temperature of four less than Baidu.

- Q:The difference between the ceramic fiber blanket and rock cotton blanket

- The heat capacity (heat storage capacity) of ceramic fiber lining is low: the heat capacity of ceramic fiber is only about l/10 of light heat resistant lining and light castable lining, and the heat capacity of lining material is proportional to the weight of lining. Low heat capacity means the furnace in the reciprocating operation absorb less heat and heating speed, greatly reducing the operational control of the temperature in energy consumption, especially for heating furnace and furnace, furnace shutdown has obvious energy saving effect.

- Q:Is the ceramic fiber cloth poisonous?

- Aluminum silicate fiber textiles can replace asbestos textiles, widely used in metallurgy, chemical industry, ceramics. Glass, refractories, shipbuilding, aerospace, automotive, machinery, electronics, building materials, light industry and other industrial sectors of the fire-resistant, heat insulation, fire prevention, friction, sealing, silencing, labor protection, high temperature filtering etc..Landlord, it seems that this material is non-toxic, rest assured that the use of good.

- Q:What are the main differences between an ordinary furnace and a ceramic fiber furnace?

- Energy saving: ordinary furnace heat loss, heat rate, furnace insulation can. The holding time of ceramic fiber furnace is ten times higher than that of ordinary furnace, and it is easy to quench and quench.

- Q:Ceramic fiber material fire shutter door how many square?

- Now there are two kinds of rolling to use ceramic fiber: a called inorganic super fire shutter (commonly known as the double track curtain), the curtain surface is glass fiber cloth + ceramic fiber cloth + ceramic fiber blanket + aluminum foil cloth, one is WFJ (glass fiber cloth + ceramic fiber cloth + glass fiber cloth).

- Q:What is the density of ceramic fiber modules? The best insulation effect

- Ceramic fiber module density is only a standard in the world, is 220Kg/m fand, but in the actual application, according to the heat treatment furnace, furnace temperature, combustion medium, temperature rise requirement of ceramic fiber module density in 200-240Kg/m fand, ceramic fiber blanket, because the processing of ceramic fiber module uses double roller today advanced technology and technology of silk, fiber length of the ceramic fiber blanket which produced in 80-130 mm, so the maximum density of the ceramic fiber module is more than the density, 240Kg/m fand, a large amount of fiber fracture, the fracture rate is as high as 48%. So after the actual verification at home and abroad of tens of thousands of industrial furnaces, the best density of ceramic fiber module is fand 220Kg/m.

- Q:Aluminum silicate needle carpet and ceramic fiber insulation performance of the good

- Aluminosilicate ceramic fiber has two different production processes, respectively, the rejection process and the blowing process. The carpet produced by the spinning process has long fiber length, high tensile strength and wide range of use. The blanket produced by blowing process is short in length and easy to break, and the scope of application is relatively narrow.

- Q:Should the ceramic fiber furnace be compacted?

- The simplest, the least durable method, uses ceramic fiber blankets for wrapping, which is often caused by the poor density of the ceramic fiber blanket and the lack of anchorage

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Pure White Thermal Insulation Blown Ceramic Fiber Bulk

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords