PU PVC Conveyor Belt Food Processing Usage

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Food Processing Conveyor Belt

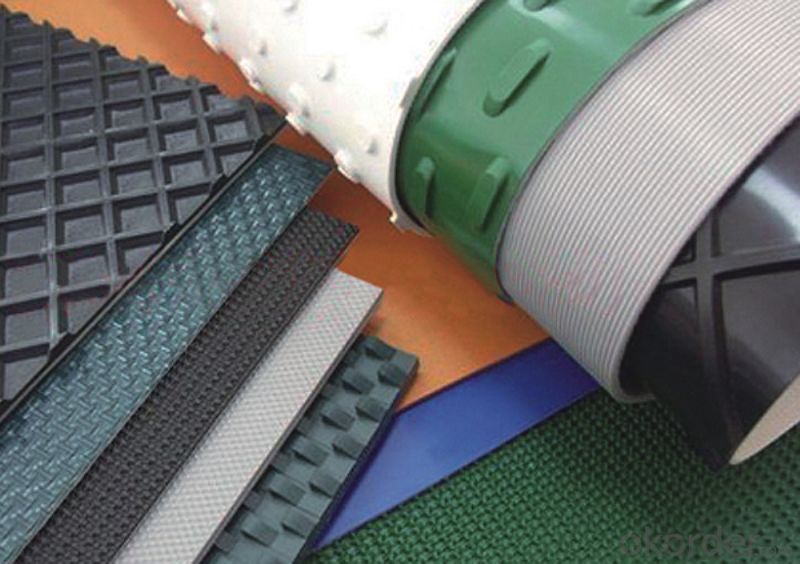

Food Processing Conveyor Belt Introduction

Food processing conveyor belt choose high quality high strength polyester fabric are the core, coated with PU or PVC as loading surface. With advantages of good flexibility, material environmental friendly, light duty, high tensile strength, anti oil, easy learning, our food processing conveyor belt meet EU and USA market requirements.

Food Processing Conveyor Belt Application

Food processing conveyor belt is widely used in food industry, such as vegetables, snack food, beer, sea food, etc.

Food Processing Conveyor Belt Advantage

Food processing conveyor belt is made of harmless material, no toxicity, no smell, anti-oil, easy cleaning, high tensile strength, good flexibility, light weight, solid and durable.

Food Processing Conveyor Belt Specifications

Total thickness(mm) 0.8~5.0 | Top coating hardness( Shore A) 55~92 |

Total weight(kg/m2) 0.9~5.4 | Belt tension 1% elongation(N/mm) 5~ 30 |

Minimum production width(mm) 15~180 | Working temperature range(℃) -20/+90 |

Type of support R=expansion cylinder, S=flat, T=groove shape | Max production width(mm) 3000 |

Lateral stability Yes | Food grade Yes |

Low noise | Fire resistance |

Surface antis tatic |

Food Processing Conveyor Belt Photos

FAQ

1. Which payment do you accept?

For you convenience, our payment can be L/C, TT

2. Is free sample available?

We can supply free samples. You'll just need to pay for express cost.

3. How about your quality?

Quality is the first priority, we have strict quality control system.

1) All raw material we used are environmental freindly

2) Quality Control Department specially responsible for quality checking in each process. We make testing on incoming raw material and finished products. Your third party testing is also welcomed.

3) Skillful workers care every details in handling the producing and packing processes.

Our product quality is accepted by clients from all over the world. Warmly welcome your samples requirement or trail order.

- Q:Can olive nets be used for olive tree protection from animals?

- Yes, olive nets can be used for olive tree protection from animals. Olive nets are commonly used to prevent animals such as birds, squirrels, or other pests from accessing the olives. These nets are designed to cover the entire tree or specific branches, creating a physical barrier that keeps animals away from the olives. Additionally, olive nets can also protect the olives from potential damage caused by strong winds or extreme weather conditions.

- Q:How does an olive net affect the overall erosion control in the olive grove?

- An olive net can significantly improve erosion control in an olive grove. By covering the ground beneath the trees, the net prevents soil erosion caused by heavy rainfall or strong winds. It also helps retain moisture in the soil, reducing water runoff and promoting healthy root growth. Additionally, the net acts as a barrier, preventing soil compaction and protecting the topsoil from being washed away. Therefore, the overall effect of an olive net is to enhance erosion control and maintain the stability and productivity of the olive grove.

- Q:Are there any other plastic products besides stretch?

- Ductility refers to the degree of temper used. Forging material without annealing can be malleable material. Temper rolling, annealing and rolling to temper. Brittle material in the temper rolling after the degree of L is poor. The object under the action of external force can be extended into filaments and properties called ductility fracture;

- Q:How does an olive net work?

- An olive net is a type of netting used in olive orchards to help with the harvesting process. It is typically laid out underneath the olive trees, and when the olives are ripe and ready to be harvested, the branches are gently shaken or mechanically agitated, causing the olives to fall onto the net. The net acts as a catchment system, preventing the olives from falling directly onto the ground and potentially getting damaged. Once the olives have been collected on the net, they can be easily gathered and transferred into containers for further processing.

- Q:Can olive nets be customized for different orchard sizes?

- Yes, olive nets can be customized for different orchard sizes. Olive nets are available in various dimensions and can be tailored to fit the specific size and shape of different orchards.

- Q:Do olive nets affect the size of the olives?

- Yes, olive nets can affect the size of the olives. Olive nets are used to protect the olives from birds and other pests, preventing them from pecking or damaging the fruits. By providing this protection, the nets allow the olives to grow without interference, potentially resulting in larger-sized olives compared to those not protected by nets.

- Q:How do you prevent olive nets from damaging the branches or leaves of the olive trees?

- To prevent olive nets from damaging the branches or leaves of olive trees, it is crucial to ensure proper installation and maintenance of the nets. Here are a few key steps: 1. Choose high-quality nets: Opt for nets specifically designed for olive harvesting, which are made of durable and lightweight material. These nets should have small enough mesh size to prevent branches and leaves from getting entangled. 2. Install the nets correctly: Prior to installation, inspect the tree branches for any sharp or protruding objects that could potentially rip the net. Secure the net tightly around the tree trunk, ensuring it is adequately spread over the tree canopy. 3. Regularly check and adjust the nets: Regularly monitor the nets during the harvesting period to ensure they are properly positioned and not causing any undue pressure on the branches or leaves. Adjust the nets if needed to evenly distribute the weight of the olives. 4. Timely harvesting: Harvest the olives when they are fully mature but still firm to reduce the risk of branches or leaves breaking under the weight. Promptly remove harvested olives from the nets to minimize prolonged pressure on the tree. 5. Prune and trim the trees: Regular pruning helps maintain a balanced and open structure for the olive trees. Trim away any excessive or weak branches that could potentially get tangled in the nets, reducing the risk of damage. By following these preventive measures, olive nets can effectively protect the harvest without causing harm to the olive trees' branches or leaves.

- Q:Can olive nets be used in combination with rootstock selection methods?

- Yes, olive nets can be used in combination with rootstock selection methods. The use of olive nets can help protect the trees from pests, birds, and other environmental factors, while rootstock selection methods can ensure optimal growth, disease resistance, and fruit quality. The combination of these two techniques can contribute to a successful olive cultivation.

- Q:Is there a difference between recycled plastics and new ones?

- Polyvinyl chloride: more obvious discoloration after regeneration, once after the extrusion will have a light brown, and three times almost become opaque brown. The specific viscosity is unchanged at two times, and tends to decrease more than two times. Both hard and soft PVC shall be joined with stabilizers. In order to make the product shiny, ABS 1% - 3% can be added when recycled.

- Q:The working principle of plastic mould

- First of all in the plastic injection machine bottom heating barrel heating melt, then the injection machine screw or plunger driven by the gating system of injection machine and mold nozzle into the mold cavity plastic molding cooling sclerosis strippingget products.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PU PVC Conveyor Belt Food Processing Usage

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 6000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords