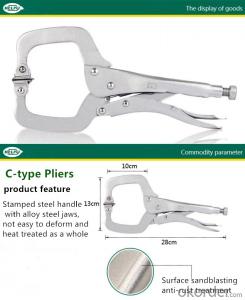

PSquare Tube Aluminum Handle Saw Frame SJ-0132

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Adjustable saw frame:8"/10"/12",

surface treadment:chrome plating, plastic spraying, corrosion resistance,with non-slip handle.

Saw blade:18TPI,carbon steel product whole steel structure, with non-slip handle. Can cut steel, wood, plastic stool rod type, durable

Our Services

1.Well-trained and experienced staffs to answer your enquirers within 24hrs.

2.OEM&ODM or customized tools are available.

3.We have strict test and QC system to guarantee the high quality.

4.Track the order until you get the goods.

We can supply the sampe for inspect,but the sample cost and freight paid by customers

We have a special team for oversea marketing service,if there is any query,please feel free to contact with us.

- Q:How to saw blade

- Saw tooth, there are many methods to open edge, still continue to use the method of the most common and most primitive is: first, put a good tooth tooth breaking material, Baicheng s type material three times. According to the 1 real - Jagged jagged teeth (2 teeth left off about 0.5-1 mm) - 3 - the real tooth tooth tooth to break 4 (tip of about 0.5-1 mm) - 5 real - Jagged jagged teeth (6 teeth of Xiang Zuobo about 0.5-1 mm) order cycle breaking after the end, breaking the material with triangle file (file of sawtooth blade and the angle of 90 degrees to file each pin, the sawtooth) each saw tooth cutting, leveling, saw blade tension, ok.

- Q:What is sawing? What's the function of it?

- When the saw blade is made, all the saw teeth are staggered according to a certain rule, and they are formed into a definite shape side by side, which is called sawing road. Saw a wave shaped and cross shaped, with a saw blade, so that the kerf width is greater than the thickness of the blade back, thereby preventing the clamping saw blade and blade wear and reduce overheating.

- Q:Do you have to replace the carbon brush for the curve saw?

- Do not need the original, as long as the model is OK, it is not so easy to bad rotor, unless you install improperly burned rotor

- Q:What is the best saw for sawing ivory?

- Secondly Lahua saw, technical requirements for Qualcomm Changping whole is not good, the lowest loss.Electric wire type. High smoothness, loss according to the thickness of wire saw.

- Q:What's the use of a steel saw?

- Carpentry mainly uses it in the fine, multi turn artistic modelling, the writing, the pattern soaring.

- Q:What are the brands of imported German band saw blades? What's the performance like?

- Saw sales point made of the Hunan Liaoning Benxi Sl talcomSaw blade cost control is a comprehensive thing, one is the quality of saw, there is the quality of sawing machine, as well as the relationship between operators, in fact, is very important

- Q:How can the cutter change the saw blade?

- When removing parts, mark and record parts according to the order in which they are disassembled.3. Change the new saw blade.4, according to the disassembly parts of the reverse order and mark, reset parts.5 tighten the fastening nut.6 、 test run to see whether the saw blade is stable or not. That is to complete the saw blade work.

- Q:Woodworking, DIY power tools, curve saws and circular saws, which is more practical?

- Their use is different, can not be replaced, the curve saw is mainly cutting arc, cutting straight line can also, but the performance is too bad, electric circular saws are mainly cutting wood, wood side, sticks, etc., convenient and quick. It's not what a curve saw can do.

- Q:What are the types of curve saw blades?

- The gray handle saw blade is especially suitable for cutting softwood, three plywood and fiberboard, and also acts on hardwood and plywood.

- Q:Why do fitter saws T8, T10, T12 and other steel materials work harder than saw 10,20 steel, and the saw blades tend to be dull?

- T8, T10 and T12 are carbon tool steels. They are very hard. The Brinell hardness in annealed state is more than 300.Manual saw blade is T12 material, just quenching, hardness is greater.10 and 20 are low carbon, high quality structural steel, very soft, Brinell hardness is less than 155.Therefore, the fitter saw, laborious, the saw is very easy to wear.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PSquare Tube Aluminum Handle Saw Frame SJ-0132

- Loading Port:

- Ningbo

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords