PS Foamed Picture Frame Extrusion machines equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

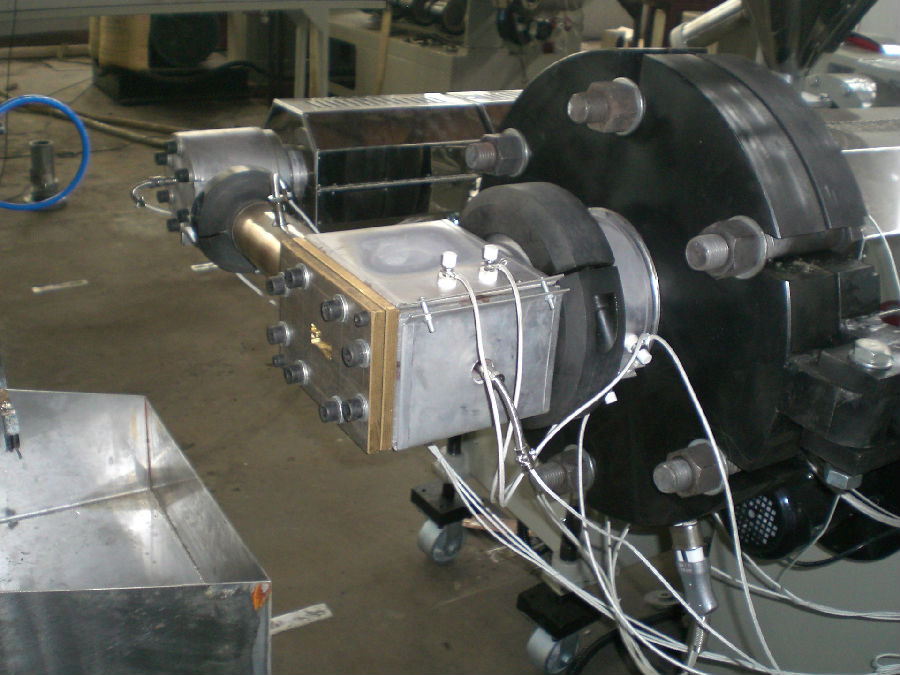

PS Foamed Picture Frame Extrusion machines equipment

1- Foamed Polystyrene Profile Extrusion Equipment for PS decoration can make Polystyrene Foamed Skirting Profile, Polystyrene Foamed Decoration Profile, Polystyrene Foamed Picture Frame, Mirro Frame, Photo Frames, which can replace the tradition wooden frame profiles, the costs are much lower and the quality is much better than wooden profiles.

2- The main raw materials are recycled PS, mixing with little some other additives in different formulas, such as HIPS, EPS, Foaming, DOP TiO2 (about 4-5 kinds), this can get different quality profiles for various application, adopting low foam technology which can save more materials cost in production for Foamed Polystyrene Profile Extrusion Equipment for PS decoration.

(1) High-speed Mixer: THE FIRST STEP before Foamed Polystyrene Profile Extrusion Equipment for PS decoration.

(2) Hot-stamping & Embossing Machine: the most advanced technology to decide profile quality.

(3) PS Profile Crusher: Recycle waste head materials and damaged profiles to crush less than 15mm

Main technical parameters:

Model | Production line speed | Production line power (KW) | Appearance size (mm) |

PS65 | 2-6m/min | 50 | 27000×1600×2100 |

PS75 | 2-7m/min | 60 | 28000×1600×2100 |

PS90 | 1-5m/min | 90 | 33000×1700×2100 |

PS100 | 1-6m/min | 100 | 34000×1700×2100 |

PS120 | 1-3m/min | 130 | 35000×1700×2100 |

- Q:Extrusion machine operating procedures, specific points, thank you!

- 11 prohibit the use of hand to touch the dry test machine high-voltage appliances, electrical wiring or ground wire parts.No water on the 12 wire core.13, do not stop before the hand touch insulated wire core, wire connector and exposed parts; after high voltage breakdown, the wire core should first take discharge measures, and then repair.14 driving and parking should be directed by skilled workers to avoid misuse and risk.15, equipped with softening equipment, plastic machine, the operator can not arbitrarily move, adjust electrical and mechanical equipment; can not touch the wire, electric pulley, copper catheter parts.16 after the end of the drive, the power supply, water source and air source should be all closed, and the operation handle will be replaced in place, and the records of the shift shift will be kept in good order.

- Q:How to adjust the 65 screw gap in the extruder?

- This should be practical learning. The outlet plane of the barrel is about 3 mm in diameter.

- Q:What is the temperature setting of the extruder and how much is the setting temperature of the head and filter?,

- The temperature setting of the extruder is related to the material you manufacture. If the type of plastic is different, the setting temperature is different, and the material of different manufacturers is also slightly different from the temperature setting. Setting the temperature completely depends on the actual situation.Generally, the position of the leaky hopper is lower than the temperature of the extruder barrel and the die head

- Q:What is the adjustment method of China's extrusion machine die?

- (2) run mode: plastic glue on the plasticizing after adjustment for mold screw, die according to how much glue circle, ran glue, side adjustment, adjustment should be loose thin screws, tighten the screws run glue thick; at the same time sampling check plastic thickness is eccentric, until evenly so far, then tighten the screw die respectively.

- Q:Where is the Huangyan extruder machine?

- You want to see what type of mold processing, but Masino comprehensive, injection mold, blow mold, mold and so on can be developed.

- Q:What is the waste gas produced by the extruder, granulator and mixer?

- Do you want water spray, dry filter, carbon adsorption, fan, and discharge? Will that be better, thank you?Chasing the answerIf the exhaust gas contains acid and alkali waste gas (slightly acid base acceptable), there is no need to water spray, the main role of water spray is used to neutralize the acid and alkali containing exhaust gas. The exhaust gas is dry organic waste gas, only dry filter, activated carbon adsorption odor can be discharged.

- Q:Why will the extruder frequency shift stop?

- Because the frequency converter is out of order, you can look at the fault record parameters of the inverter.

- Q:Taper twin screw extrusion machining of plastic masterbatch? What ancillary equipment do you need?

- Can, but need feeding machine and related auxiliary mixing granulator, the cost is not low, but the effect is less than double make flat,

- Q:Comparison of injection molding machines and Extruders

- The plastic to replace steel or nonferrous metal, plastic cement, which is widely used in agriculture, building materials, packaging, machinery, electronics, automobiles, household appliances, petrochemical and defense, extruder and daily life other fields. So it can be predicted that in twenty-first Century, the plastic will be one of the most important raw material of human activities. The extruder design due to extrusion molding is the main form of plastic processing, so the development of plastic extrusion molding technology and equipment has important significance. The polymer materials used in blending type mixing equipment modification there are three main types: parallelwith twin-screw extruder, reciprocating screw kneader and series disc extruder. The small corotating twin screw extruder has domestic production can squeeze But tons of large mixing extrusion granulation unit will rely on the import machine technology. At the same time. Reciprocating screw kneader and series disc extruder is a necessary device for preparing high fill and high added value of polymer alloy, the current domestic research on them is just in the prototype stage, specifications, varieties not all, have broad prospects for development.

- Q:Ask everyone about the extrusion machine at the wire factory...... How do you adjust the speed of the motor?

- Adjust the main speed buttonAskI've changed the line.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

PS Foamed Picture Frame Extrusion machines equipment

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 10 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords