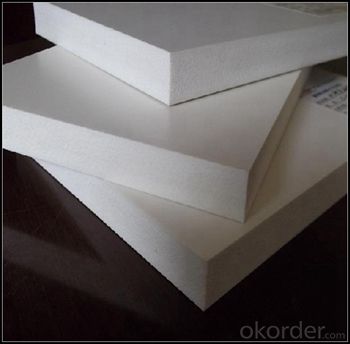

Promotion Advertisement High Density PVC Sheet White PVC Foam Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

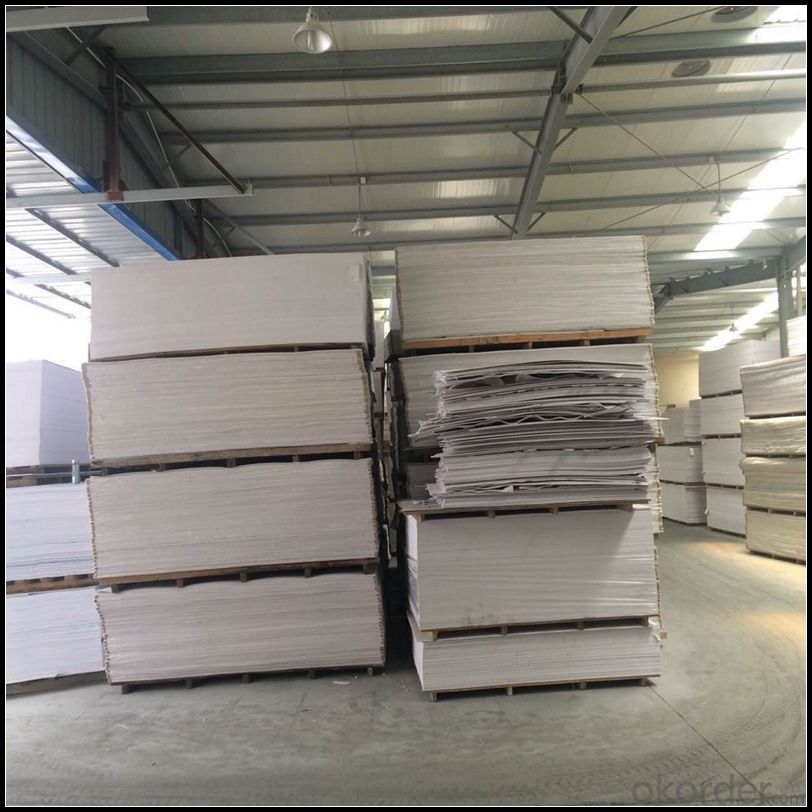

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Item specifice

Factory Price Anti Static New Material PVC Board

1.Product Introduction

PVC foam board is made from polyviny chloride, with flat plate surface, it is widely used in construction, advertising display boards, mounting board, screen printing, carving, etc.

PVC foam board / sheet / pallet is the best material in block making industry as the carrier of the green blocks, it has the advantages of highest strength with smooth surface, moisture proof and heat-resistant, it can maintain stable performance under high temperature. Waterproof, anti-corrosive ametabolic and recyclable,moisture resistant,lightweight.

2. Product Features

(1) Light weight, waterproof, fire retardant and self-extinguishing

(2) Sound insulation, heat insulation, noise absorption, heat preservation and anti-corrosion.

(3) Tough, rigid with a high impact strength, not easy to age and can keep its color for long

(4)Easy to clean and maintain.

(5)Envioronmental-firendly green and lead-free.

3. Product Application

Advertising: exhibition display, digital printing, silk screen printing, computer lettering,sign board, light box,etc.

Construction: office and bathroom cabinets, inner and outer decorate panel,commercial decorating shelf, room separating

Transportation: steamboat, airplane, bus, train carriage, roof and carriage inner layerand other industry.

Item Name | PVC Foam Board |

Density of PVC Foam Board | 0.45-1.05g/cm3 |

Characteristics | High Density, High Strength, Water-proof, No Poison |

Application | Cupboard, Bathroom, Advertising Material |

4. Characteristics:

(1) Light weight

(2) High strength

(3) Easily cleaned

(4) Easily fabricated

(5) Outstanding printability

(6) Uniform fine close cell structure

(7) Good resistance to light and weathering

(8) Low flammability

5. Pictures:

- Q:why do people put plastic sheeting down before pouring concrete? I think i know but want to here from experts.?

- It's cheating. If you did not put down enough gravel, then put down the plastic. Because when the dirt leaches water out of the concrete (or other reasons), then that part of the concrete is weak. (or in a wet area, it also creates problems). However, in all honesty, your result would be better WITHOUT the plastic underneath, and more gravel underneath (which costs more). Why? Because cured concrete is a bit of a sponge, and needs to also let the water it absorbed out. If someone later puts this inside a home by building over a patio, without enough gravel base, then this concrete would be constantly wet, and thus, would be an odd and difficult to figure out disaster of problem, perhaps even a mushroomy smell. So, in summary, for a foundation for a fountain, it's great...for sidewalks....ok as well. For a slab foundation, it's a disaster! For anything outside, where the winters are short....it's ok.

- Q:Do plastic sheets have any limitations or disadvantages?

- Yes, plastic sheets do have limitations and disadvantages. They can be prone to cracking or breaking under certain conditions, and they may not have the same level of durability as other materials. Additionally, some plastic sheets are not UV resistant and can become discolored or brittle when exposed to sunlight. They can also be less aesthetically pleasing compared to other materials and may not be suitable for certain applications that require a more high-end or natural look.

- Q:Are plastic sheets resistant to chemicals in swimming pool environments?

- Yes, plastic sheets are generally resistant to chemicals in swimming pool environments.

- Q:Can plastic sheets be recycled into other materials?

- Yes, plastic sheets can be recycled into various other materials through processes such as melting, shredding, and reformation.

- Q:I saw this on a solar panel website one time but am now unable to locate. It's a thin sheet of what appears to be plastic but it isn't clear... it's more opaque than anything. What the site claimed was that by shining the sun through this plastic (like shining the sun through a magnifying glass) you can intensify to some (great) degree onto a particular area. Anyone ever heard of it? Does this type of material exist? Is it a scam? Any information appreciate.

- sounds like a fresnel lense

- Q:Talk fast now.

- I swear that i just came back from Hunting.ha

- Q:You know how dvd cases are made of somewhat flexible plastic? Where can you find sheets of those? (if you even can)

- Michael's Crafts ;)))

- Q:Are plastic sheets resistant to chemicals in swimming pools?

- Yes, plastic sheets are generally resistant to chemicals in swimming pools. They are designed to withstand exposure to chlorine and other pool chemicals without deteriorating or reacting adversely.

- Q:Can plastic sheets be used for mold-making in manufacturing?

- Yes, plastic sheets can be used for mold-making in manufacturing. Plastic sheets are commonly used as mold-making materials due to their ability to be easily shaped, their durability, and their cost-effectiveness. They can be heated and molded into the desired shape, allowing for the creation of complex molds. Additionally, plastic sheets are resistant to many chemicals and can withstand high temperatures, making them suitable for various manufacturing processes.

- Q:What are plastic sheets made of?

- Plastic sheets are made from various types of polymers, such as polyethylene, polypropylene, or polycarbonate. These polymers are derived from petroleum or natural gas through a process called polymerization.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Promotion Advertisement High Density PVC Sheet White PVC Foam Board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords