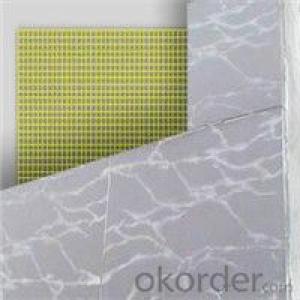

Professional fiberglass mesh roll with great price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 g/m²

- Supply Capability:

- 4000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Product Introduction

Fiberglass mesh, alkali resistant fiberglass mesh is on the basis of alkali-resistant or C-glass or E-glass woven fabric, then coated by acrylic acid copolymer liquid.

Characteristics: Good alkaline-resistance, high stength, excellent alkali and acid resistance, good cohesion, excellent in coating etc.

Uasge: Ti is widely used in wall reinforce, out side wall heat insulation, roof waterproof, reinforcement, plastic, bitumen, plaster, marble, mosaic. Etc. It is an ideal engineering material in construction.

Our best quality ablity:

1) mesh of warp and wet mesh is very straight

2)coating enough alkaline resistant glue and keep 60%-80% strength after testing in NaOH 28 days later

3)Made by C-glass or E-glass fiber roving as basis material and then treated with acrylic acid coplolymer liquid.

| Products | Weight sq.meters(g/s.m) | Mesh size (mm) | Roll size (50sq.meters) | quantity of rolls in one container 40HQ | Color | Package |

| Fiberglass Mesh | 60g | 4X4-10X10mm | 1m*50m | 4000 rolls | White | Bulk,plastic,caton or as your demand |

| (fiberglass net) | Blue | |||||

| 70g | 1m*50m | 3500 rolls | ||||

| 80g | 1m*50m | 3000 rolls | Yellow | Certification | ||

| 90g | 1m*50m | 2900 rolls | ||||

| 100g | 1m*50m | 2800 rolls | Black | ISO9001:2000 | ||

| 110g | 1m*50m | 2700 rolls | MOQ | |||

| 120g | 1m*50m | 2600 rolls | Red | 75000 or one container | ||

| 130g | 1m*50m | 2550 rolls | ||||

| 140g | 1m*50m | 2500 rolls | Green, | Delivery time | ||

| 150g | 1m*50m | 2450 rolls | ||||

| 160g | 1m*50m | 2400 rolls | etc. | 10 days |

- Q:The difference between alkali resistant mesh fabric emulsion and urine glue 7.5

- Grid cloth stereotypes are used in the market, a wide range of species, can generally be divided into urine gel, latex twoThe grid cloth made of urine gum is hard, and the quality of latex is almost worse than that of latex

- Q:Can fiberglass mesh waste be recycled? What can you do if you can?

- Mesh cloth, such as discarded cloth, is not corrosive and may not corrode for hundreds of years, causing serious pollution to the land;

- Q:How is fiberglass mesh used?

- The wall should be cleaned before paving and the pits will be patched and leveled

- Q:How to fill the sample size of glass fiber mesh cloth, fill what general specifications

- Glass fiber mesh fabric is based on glass fiber woven fabric as its base material and is coated with high polymer emulsion.

- Q:Glass fiber mesh fabric stereotypes poor, general use of glue is acrylic emulsion, please add what accessories, you can finalize a better shape

- To increase the penetration of some surface active agent, increase the permeability of the emulsion, adding some phenolic thermosetting resin, melamine formaldehyde and improve sizing effect, to prevent the resurgence of soft, adding cationic film plasticized thermosetting resin while reducing fiber absorption and softening fiber

- Q:What is the function of the wall cloth mesh?

- The main uses are widely used:1) wall reinforcement materials (such as glass fiber wall, net cloth, GRC wallboard, EPS internal and external wall insulation board, gypsum board and so on.2) reinforce cement products (such as Rome column, flue, etc.).3) granite, mosaics, special mesh, marble back net.4) waterproof coiled material and bituminous roof waterproof.5) strengthen the skeleton material of plastic and rubber products.

- Q:The building is how to choose the external wall thermal insulation material of glass fiber mesh cloth?

- When the heat of the interior passes through the wall mesh, the insulation will be cut off and retained, and when the room temperature falls. The wall of the heat will be released, by adjusting the indoor temperature; in the summer, glass fiber mesh insulation would block the sun's radiation and external heat into the room, so that the indoor situation of "cool", and the ten seasons and pleasant residential Polygonatum and physical skills improved significantly

- Q:Glass fiber mesh cloth, crack mortar, tiling there is no problem?

- Now, many sites are pure in the transfer problem of various types of work, if the base treatment bends up, after the winter freeze will soon fall, you can put the case to the party to write a material, as long as you don't sign the party a no problem.

- Q:What kind of wall fabric is covered with fiberglass mesh? Do you apply the powder or the powder? Thank you

- And the wallFully paved, just an industry standard, the requirements are yes, but rare, there are really such a use, on the one hand is the cost, on the one hand is now mostly cast-in-place, there is no need!

- Q:Can indoor glass fiber mesh cloth be stuck with wall tiles?

- Yes, glass fiber mesh is used for roofing, waterproofing and gypsum, marble, mosaic and other wall or plate reinforcement.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Professional fiberglass mesh roll with great price

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 g/m²

- Supply Capability:

- 4000000 g/m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords