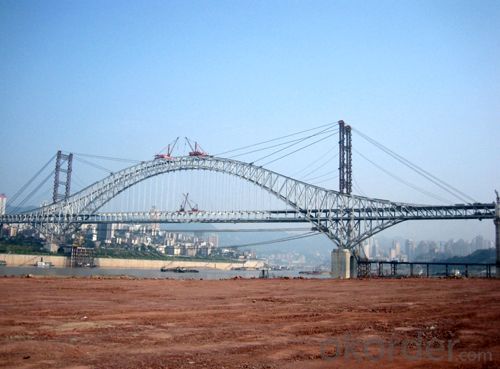

Professional Bridge Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

| Model Number | B |

| Material | Metal |

| Drawing for design | According to your requirement.We can quote according to your drawing. |

| Surface Treatment | Hot galvanized,painted,powder coated |

Packing Details

| a)Steel strip. |

| b)According to the customers' requirement |

Payments and Shipping Terms

| MOQ | 25 Ton |

| Supply Ability | 100 ton/Month |

| Payment Term | a)L/C b)T/T |

| FOB Shanghai Price | USD1000-1200/Ton |

Check Below for more imformation on placing an order

| 1. Inquiry-Professional quotation. |

| 2. Confirm the price, lead time, payment term etc. |

| 3. Our sales send the Proforma Invoice. |

| 4.Customer make the payment for deposit and send us Bank receipt. |

5.We will arrange the production & inform the estimated time. |

6. Middle Production:send photos to show the production line which you can see your products in . Confirm the estimated delivery time again. |

7. End Production:Mass production products photos will send to you for approval. You can also arrange the third party Inspection. |

8. Clients make payment for balance and we Ship the goods .Also can accept payment term-Balance against B/L Copy Or L/C payment Term. Inform the tracking number and check the status for clients. |

9. Order can be say “finish” when you receive the goods and satisfy with them . |

10. Feedback to us about Quality , Service, Market Feedback & Suggestion. And we will do better. |

- Q:What are the different types of steel walls used in construction?

- There are several types of steel walls commonly used in construction, including structural steel walls, steel stud walls, and steel curtain walls. Structural steel walls are typically used in high-rise buildings and industrial structures, providing strength and stability to the overall structure. Steel stud walls are commonly used in commercial buildings and residential construction, featuring lightweight steel framing with gypsum board or other cladding materials. Steel curtain walls are often used in modern architecture, consisting of a steel frame with large glass panels, allowing for natural light and panoramic views while providing structural support.

- Q:How are steel structures designed to accommodate for expansion and contraction?

- Steel structures are designed to accommodate for expansion and contraction through careful consideration of the materials used and the design of the joints and connections. Expansion and contraction in steel structures occur due to changes in temperature. To address this, engineers use materials with low coefficients of thermal expansion, such as stainless steel, and design joints and connections that allow for movement without compromising the structural integrity. These joints and connections may include expansion joints, sliding connections, or flexible connections that can absorb the thermal expansion and contraction, ensuring the stability and longevity of the steel structure.

- Q:What are the different methods of steel structure fire protection?

- There are several methods of steel structure fire protection that are commonly used to ensure the safety and integrity of steel structures in the event of a fire. These methods include: 1. Intumescent coatings: Intumescent coatings are a popular method of fire protection for steel structures. These coatings are typically applied to the surface of the steel and provide a protective layer that expands when exposed to high temperatures. This expansion creates a barrier that insulates the steel and slows down the heat transfer, giving more time for evacuation and fire-fighting efforts. 2. Fire-resistant insulation: Fire-resistant insulation materials, such as mineral wool or fiberglass, are commonly used to protect steel structures. These materials are installed around the steel members to provide insulation and prevent the rapid spread of fire. They help to maintain the structural integrity of the steel by reducing the heat transfer and protecting it from the direct flame. 3. Fireproofing sprays: Fireproofing sprays are another method of steel structure fire protection. These sprays are typically made of cementitious materials or fiber-reinforced polymers and are sprayed onto the surface of the steel. They form a durable protective layer that acts as a barrier against the flames and heat, minimizing the damage to the steel structure. 4. Fire-resistant boards: Fire-resistant boards, such as gypsum or calcium silicate boards, are often used for fire protection of steel structures. These boards are installed around the steel members to provide a protective barrier against fire. They are effective in preventing the heat transfer and can withstand high temperatures, thus safeguarding the steel structure. 5. Structural fire-resistant coatings: Structural fire-resistant coatings are specifically designed to protect steel structures from fire. These coatings are often made of epoxy-based or cementitious materials and are applied directly to the steel surface. They provide a heat-resistant layer that slows down the rate of temperature rise on the steel, preventing structural failure. It is important to note that the selection of the appropriate method for steel structure fire protection depends on factors such as fire rating requirements, building codes, and the specific environment in which the structure is located. Professional fire protection engineers and consultants should be involved to ensure that the chosen method is in compliance with the applicable regulations and provides the necessary level of fire resistance for the steel structure.

- Q:How is steel used in transportation infrastructure, such as airports or railway stations?

- Due to its exceptional strength, durability, and versatility, steel finds widespread usage in transportation infrastructure, including airports and railway stations. One of the primary applications of steel in transportation infrastructure involves utilizing it for the construction of main structural components such as beams, columns, and trusses. These elements form the framework for buildings, terminals, and platforms, ensuring stability and the ability to bear heavy loads. In airports, steel sees extensive use in the construction of hangars, terminals, and control towers. The lightweight nature of steel structures, combined with their high strength, allows for the creation of large open spaces and flexible designs. This proves especially crucial in airport terminals where there is a need for wide, open areas to accommodate a large number of passengers and support heavy mechanical and electrical systems. Steel is also employed in the construction of overhead walkways, escalators, and elevators, ensuring the safe movement of passengers within the airport. Similarly, in railway stations, steel plays a crucial role in the construction of platforms, bridges, and tunnels. Steel platforms provide a strong and stable surface for passengers to embark and disembark from trains. Steel bridges are commonly used to span over water bodies or other obstacles, enabling trains to pass through smoothly. Steel tunnels provide a protective enclosure for railway tracks, ensuring the safety of trains and passengers. Moreover, steel is chosen for transportation infrastructure due to its corrosion resistance properties, which prove particularly important in areas exposed to harsh weather conditions. Steel structures are often galvanized or coated with protective layers to prevent rust and deterioration, leading to an increased lifespan and reduced maintenance costs. Additionally, steel is valued for its fire-resistant properties in transportation infrastructure. Steel structures are designed to withstand high temperatures, providing a safe environment for passengers in case of fire emergencies. In conclusion, steel is an indispensable material in transportation infrastructure, including airports and railway stations, due to its strength, durability, versatility, corrosion resistance, and fire-resistant properties. Its use in constructing the main structural components ensures stability and load-bearing capacity, while also allowing for flexible designs and large open spaces. Overall, steel plays a vital role in the creation of safe and efficient transportation hubs for travelers worldwide.

- Q:How are steel structures designed to resist lateral loads?

- Steel structures are designed to resist lateral loads through various methods such as the use of bracing systems, shear walls, moment-resisting frames, and base isolation techniques. These elements are strategically incorporated into the design to provide stability and strength against lateral forces, such as wind or seismic loads. The choice of the specific design method depends on factors like the type of structure, local building codes, and anticipated loads. Overall, steel structures are engineered with careful consideration of lateral load resistance to ensure their safety and stability.

- Q:What are the design considerations for steel theme parks?

- Some design considerations for steel theme parks include structural integrity, durability, aesthetic appeal, and ease of construction. Steel is a popular choice for theme park structures as it offers high strength and flexibility, allowing for creative and ambitious designs. The materials used must be able to withstand heavy loads, extreme weather conditions, and the wear and tear of constant use. Additionally, the design should prioritize visitor safety and comfort, incorporating elements such as shade structures, seating areas, and efficient crowd flow.

- Q:How are steel structures installed on-site?

- On-site, steel structures are typically put in place through a well-coordinated and systematic process. Initially, the site is prepared by clearing the area and establishing a level foundation. Once the site is ready, the steel components are delivered and unloaded. The installation commences with the assembly of the steel framework. This entails connecting different steel members like columns, beams, and trusses using bolts or welding. With great care, the steel components are aligned and secured to guarantee the overall system's structural integrity. To facilitate installation, cranes or other lifting equipment are employed to position the steel members accurately. This requires skilled operators who maneuver the components with precision according to design specifications. As the installation progresses, temporary bracing may be utilized to stabilize the structure until all the components are in place. Once the framework is completed, secondary steel elements like stairs, handrails, and platforms are added to finalize the structure. Throughout the installation process, strict adherence to safety measures ensures the workers' protection and a secure work environment. This includes the use of personal protective equipment, proper lifting techniques, and regular inspections to identify any safety hazards. Upon the full installation of the steel structure, a final inspection is conducted to verify the proper alignment and securement of all components. Any necessary adjustments or corrections are made at this stage to ensure compliance with building codes and regulations. In conclusion, the installation of steel structures on-site requires meticulous planning, skilled labor, and the use of heavy equipment. The process encompasses site preparation, assembly of the steel framework, precise lifting and positioning of components, installation of secondary elements, and final inspections. By following these steps, a robust and enduring steel structure can be successfully erected.

- Q:What are the key considerations in the design of steel structures for industrial applications?

- When designing steel structures for industrial applications, there are several key considerations that need to be taken into account. Firstly, the structural integrity of the steel structure is crucial. Industrial environments often involve heavy machinery, high loads, and potential impacts, so the structure needs to be able to withstand these forces. The design should include appropriate load calculations, considering not only the static loads but also dynamic loads and potential vibrations. Secondly, the durability of the steel structure is important. Industrial environments can be harsh, with exposure to extreme temperatures, humidity, chemicals, and corrosion. Therefore, the choice of steel grade and protective coatings is critical to ensure the structure remains in good condition over its intended lifespan. Another key consideration is the functionality and layout of the industrial space. The design should take into account the specific requirements of the industrial processes, including the placement of equipment and machinery, access points, and workflow efficiency. The structure should be flexible enough to accommodate potential future modifications or expansions. Safety is also a crucial consideration in the design of steel structures for industrial applications. The design should adhere to all relevant safety standards and regulations, including fire safety, escape routes, and emergency systems. Adequate provision should be made for the installation of safety features such as handrails, guardrails, and safety barriers. In addition, cost-effectiveness is an important consideration. The design should aim to optimize the use of materials and minimize construction time and costs while still meeting the required performance and safety standards. Lastly, sustainability and environmental impact should be considered. Designing steel structures with energy-efficient features, incorporating renewable energy sources, and using recyclable materials can contribute to reducing the environmental footprint of industrial applications. Overall, when designing steel structures for industrial applications, it is crucial to consider structural integrity, durability, functionality, safety, cost-effectiveness, and sustainability to ensure a successful and efficient industrial facility.

- Q:How are steel structures designed to resist wind-induced vibrations?

- Steel structures are designed to resist wind-induced vibrations through a combination of structural engineering techniques. These include the use of stiffening elements like bracing or shear walls to increase the overall rigidity of the structure. Additionally, aerodynamic considerations such as the shape and profile of the building are taken into account to minimize wind loads. Damping devices, such as tuned mass dampers or viscous dampers, may also be incorporated to absorb and dissipate vibrations. Furthermore, computer simulations and wind tunnel testing are conducted to analyze the structural response to wind, ensuring the design can withstand the anticipated wind loads and vibrations.

- Q:How do steel structures contribute to the overall sustainability of a building?

- There are several ways in which steel structures enhance the overall sustainability of a building. To begin with, steel possesses exceptional durability and a long lifespan. Consequently, steel structures necessitate less maintenance and replacement over time in comparison to alternative building materials. This durability diminishes the requirement for regular repairs and renovations, thereby decreasing the overall environmental impact of the building. Furthermore, steel is a recyclable material. At the conclusion of a building's life cycle, it is effortless to dismantle steel structures and recycle the steel for alternative purposes. This reduces the quantity of waste generated during the demolition process and minimizes the depletion of natural resources. Moreover, steel structures present design flexibility, permitting efficient utilization of space and the capability to adapt to changing needs. This flexibility implies that buildings can be easily modified or expanded without extensive demolition or reconstruction. Consequently, construction waste is reduced, contributing to the overall sustainability of the building. Additionally, steel is a lightweight material when compared to other construction materials like concrete. This lightweight characteristic facilitates easier transportation and assembly, resulting in reduced energy consumption during construction and minimized carbon emissions during transportation. Lastly, steel structures possess high resistance to fire, earthquakes, and other natural disasters. By providing a secure and safe environment, steel structures increase a building's longevity and reduce the necessity for reconstruction following a disaster. This resilience minimizes the environmental impact of rebuilding and decreases the risk to human life, thus contributing to the overall sustainability of the building. In conclusion, steel structures enhance the overall sustainability of a building due to their durability, recyclability, design flexibility, lightweight nature, and resilience. By selecting steel as a building material, we can construct structures that are not only environmentally friendly but also cost-effective and safe for occupants.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Professional Bridge Steel

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords