Printing Tinplate Coils With Prime Quality for 0.23mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Printing Tinplate Coils With Prime Quality for 0.23mm

1.Structure of Description

Printing Tinplate Coils With Prime Quality for 0.23mm is one of the metal packing materials, which is widely used for making painting cans ,chemical package cans , electrical cable ,battery and metal printing etc.

2. Main Features

Steady and high quality

Fast shipment

Good experience for export work

For the surface, Plate uniform in thickness,uniform and smooth tin coating, without flaws,rusts,scratch,wave,nick of tin coating etc.

Price competitive

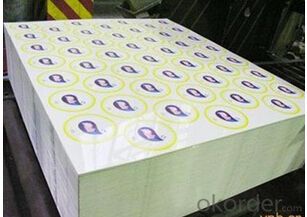

3. Images

4. Specification

Standard : GB2520-2000 ,JIS G3303

Steel type : SPCC

Coating : 2.8/2.8

Surface: Bright, Stone ,

Thickness:0.31

Width :600MM~1000MM

Temper : T1~T5

Package: tinplate wrapped completely with an inner cover of plastic or waterproof papers with vorners protected with metal angels.

5.FAQ

A. What is the package of tinplate? (Referred as below)

For sheets, thin plastic film + rust-proof paper + metallic cover + metallic angles+ steel band strips + fumigated wooden pallet.

For coil, thin plastic film + rust proof paper + metallic cover + steel band strips + fumigated wooden pallet

B. The surface of tinplate could you supply?

Stone finish, Bright finish, Matte finish, Silver finish

C. What quantity is the minimum order of tinplate?

Usually, the minimum quantity is 25MT. For special case, consult with us.

D. Can it make to be BA or CA for annealing?

Yes, both can do with.

- Q:What is tin plate?

- Tinplate is classified according to thickness and tinning. Generally speaking, in order to save costs, the current industrial production will reduce the iron thickness and tin content while guaranteeing the reliable strength of the package. One is to use less or even no tin tin (chrome iron), by 50s the development of hot dip tin plating tin to the present, China has not see the hot dip in the use of tinplate cans.

- Q:Can tinplate be used for solar panel applications?

- Yes, tinplate can be used for solar panel applications. Tinplate is often used as a protective coating for solar panels due to its corrosion resistance and ability to reflect sunlight. It acts as a barrier against moisture and environmental elements, ensuring the durability and longevity of the solar panels. Additionally, tinplate can enhance the overall efficiency of solar panels by reducing heat absorption and improving energy conversion.

- Q:What are the different types of tinplate closures available?

- There are several types of tinplate closures available, including twist-off caps, crown caps, lug caps, and screw caps.

- Q:Tin, tin plated iron. Why can't we get white wine?

- Passivation of the tinplate, if further coating, will be very good corrosion resistance, but these coatings are not resistant to alcohol.In short, tinplate is afraid of water, but also afraid of alcohol, so it can not be loaded white wine.

- Q:Can tinplate be used for packaging beauty and skincare products?

- Yes, tinplate can be used for packaging beauty and skincare products. Tinplate is a commonly used material in the packaging industry due to its durability, corrosion resistance, and ability to protect products from external factors. It is also easily customizable, allowing for attractive and eye-catching designs that can enhance the appeal of beauty and skincare products.

- Q:Can tinplate be painted or coated with other materials?

- Yes, tinplate can be painted or coated with other materials.

- Q:What are the main challenges in tinplate warehousing?

- One of the main challenges in tinplate warehousing is the fragile nature of the product. Tinplate is susceptible to scratching, denting, and corrosion, so careful handling and storage procedures are necessary to prevent damage. Additionally, due to its relatively low melting point, tinplate requires proper temperature and humidity control to avoid deformation or discoloration. Lastly, tinplate is often packaged in large and heavy rolls, making logistics and space utilization critical challenges in warehousing operations.

- Q:How does tinplate affect the recyclability of mixed-material packaging?

- Tinplate plays a significant role in enhancing the recyclability of mixed-material packaging. It is highly recyclable and has a well-established recycling infrastructure worldwide. By incorporating tinplate into mixed-material packaging, it enables easier separation of different materials during the recycling process. Tinplate's recyclability helps reduce waste and conserve resources by enabling the recovery and reuse of valuable materials, ultimately promoting a more sustainable packaging system.

- Q:Can tinplate be used for packaging hazardous materials?

- Yes, tinplate can be used for packaging hazardous materials. Tinplate is a type of steel coated with a thin layer of tin, providing excellent resistance against corrosion and creating a protective barrier. This makes it suitable for containing and transporting hazardous materials safely, as it helps prevent leaks or contamination. Additionally, tinplate is also recyclable, making it an environmentally friendly choice for packaging hazardous substances.

- Q:What are the main challenges in tinplate transportation?

- The main challenges in tinplate transportation include ensuring proper packaging and securing of the tinplates to prevent damage during transit, managing the weight and volume limitations imposed by transportation regulations, coordinating logistics and transportation routes to minimize delivery times and costs, and addressing potential issues related to customs and import/export regulations for international shipments. Additionally, maintaining product quality and preventing contamination or corrosion during transportation are also important challenges to overcome.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Printing Tinplate Coils With Prime Quality for 0.23mm

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords